• Fully open the shutoff valves on the liquid and gas sides after the

refrigerant replenishment is finished.

The compressor will malfunction if the system is operated with the

shutoff valves closed.

• Apply a screw lock agent to the screws of the valve cover

mounting parts and service ports.

(Otherwise, dew condensation water will intrude and freeze inside

and cause cap deformation or damage, which may result in

refrigerant gas leakage or compressor malfunctions.)

11. TEST RUN

For test run operators

Do not operate the outdoor unit alone on a trial basis.

Test run procedure

Use the following procedure to perform a test run after installation

work is complete for the entire system:

1. Fully open the shutoff valves on the gas and liquid sides of the

outdoor unit.

2. Set the operation switch of the outdoor unit to ON.

Note: Before turning power on, check that the piping cover and

control box lid of the outdoor unit are closed.

3. Check the sealing condition of the outdoor unit through the sight

glass. Make sure that the amount of refrigerant is sufficient.

4. Make sure that cold air blows from the indoor unit.

Check that the internal temperature is dropping.

(Check that the temperature will drop and reach the set

temperature in the internal unit. It will take approximately

40 minutes for the interior temperature of the internal unit to reach

–20°C.)

Check that the indoor unit (for refrigeration or freezing) goes into

defrosting operation.

5.

Turn power off with the operation switch of the outdoor unit set to OFF.

(Stopping unit operation by disconnecting the power supply directly

is dangerous. When the unit is stopped in this manner, its power

outage compensation function may cause it to resume operation as

soon as the power supply is reactivated. Additionally, stopping the

unit in this manner may cause the compressor to fail).

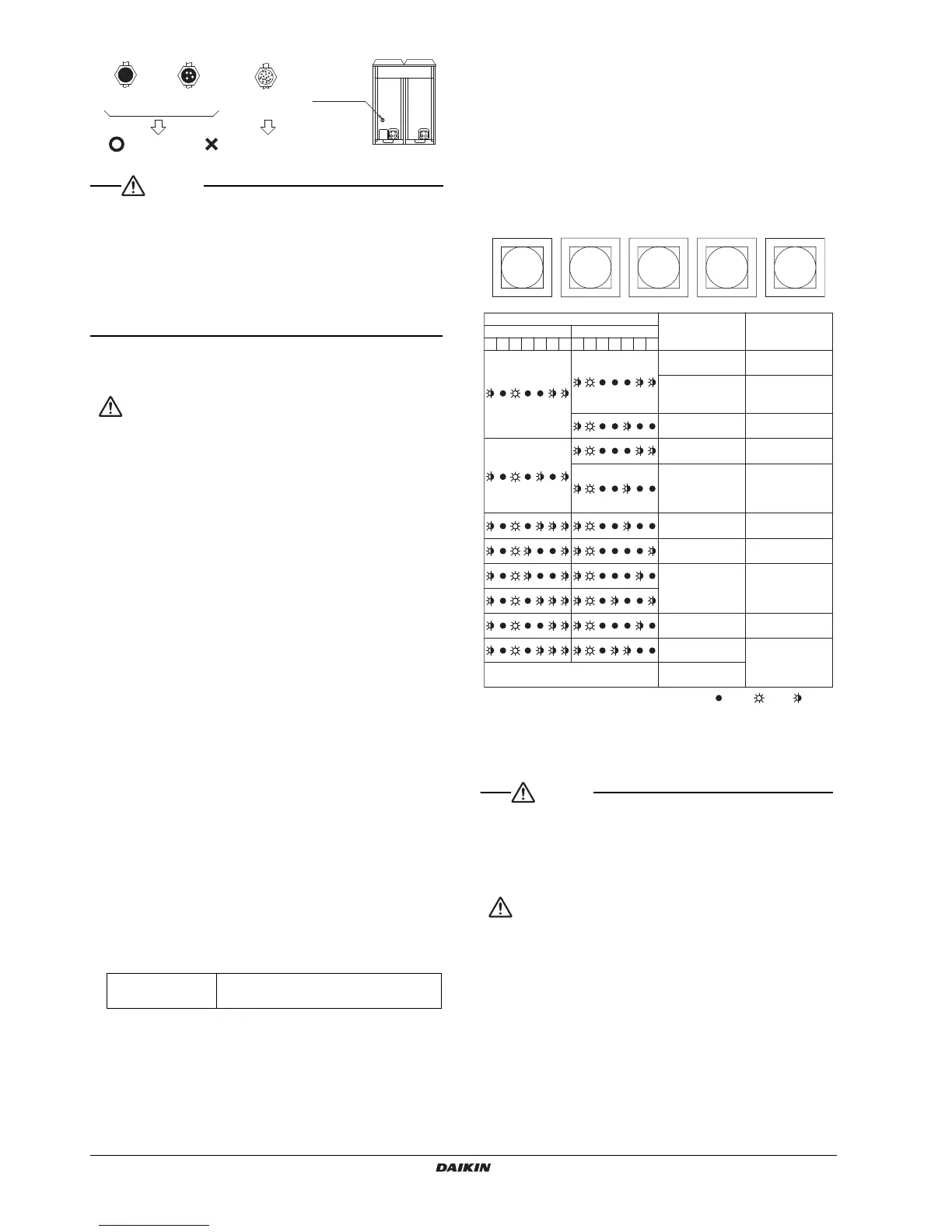

Error diagnosis

• If the system cannot operate normal at the time of test run (i.e., the

H2P indicator is lit), check with malfunction code on the system

with the pushbutton switches on the PCB of the outdoor unit, and

take the following steps.

• Make checks on other malfunction codes and pushbutton switches

by referring to the provided Technical Guide.

Display

The contents of a LED (H2P) display are as follows.

How to check malfunction code

By operating the pushbutton switches on the PCB, malfunction

code items can be displayed on the condensing unit.

1. Make sure that the LED “H1P” is off.

(If the LED is on, press the MODE button (BS1) once.)

2. Press the MODE button (BS1) once. The LED (H1P) starts

blinking.

3. Press the RETURN button (BS3) to display the first digit of the

malfunction code on the LED.

4. Press the SET button (BS2) to display the second digit of the

malfunction code on the LED.

5. Press the MODE button (BS1) to restore the LED to the original

state.

*1

Set the operation switch to the OFF position to reset the power supply

and then return the operation switch to the ON position to restart the

unit. If the problem persists, refer to the Service Manual.

• Do not disconnect the power supply for 1 minute after setting the

operation switch to ON.

Electric leak detection is performed for several seconds after the

operation switch is set to ON and each compressor starts

operating, so disconnecting the power supply during that time will

result in a false detection.

For dealers

• After the test run is finished, check that the piping cover and front

panel are mounted.

• At the time of delivery to the customer, use the operation manual

and fully explain the handling of the equipment.

• For precautions at the time of delivery, refer to the provided

installation manual for each unit as well.

LED (H2P) display

OFF.....Normal ON.....error

Blinking.....to be prepared

Loading...

Loading...