9 Configuration

Installation manual

16

RXTM30+40N2V1B + RXTP25+35N2V1B9 +

RXTP25+35N2V1B8 + ARXTP25+35N2V1B + RXTA30N2V1B

R32 split series

3P482320-10S – 2020.08

9 Configuration

9.1 Facility setting

Use this function for cooling at low outdoor temperature. This

function is designed for facilities such as equipment of computer

rooms. NEVER use in a residence or office where people occupy the

space.

9.1.1 To set the facility mode

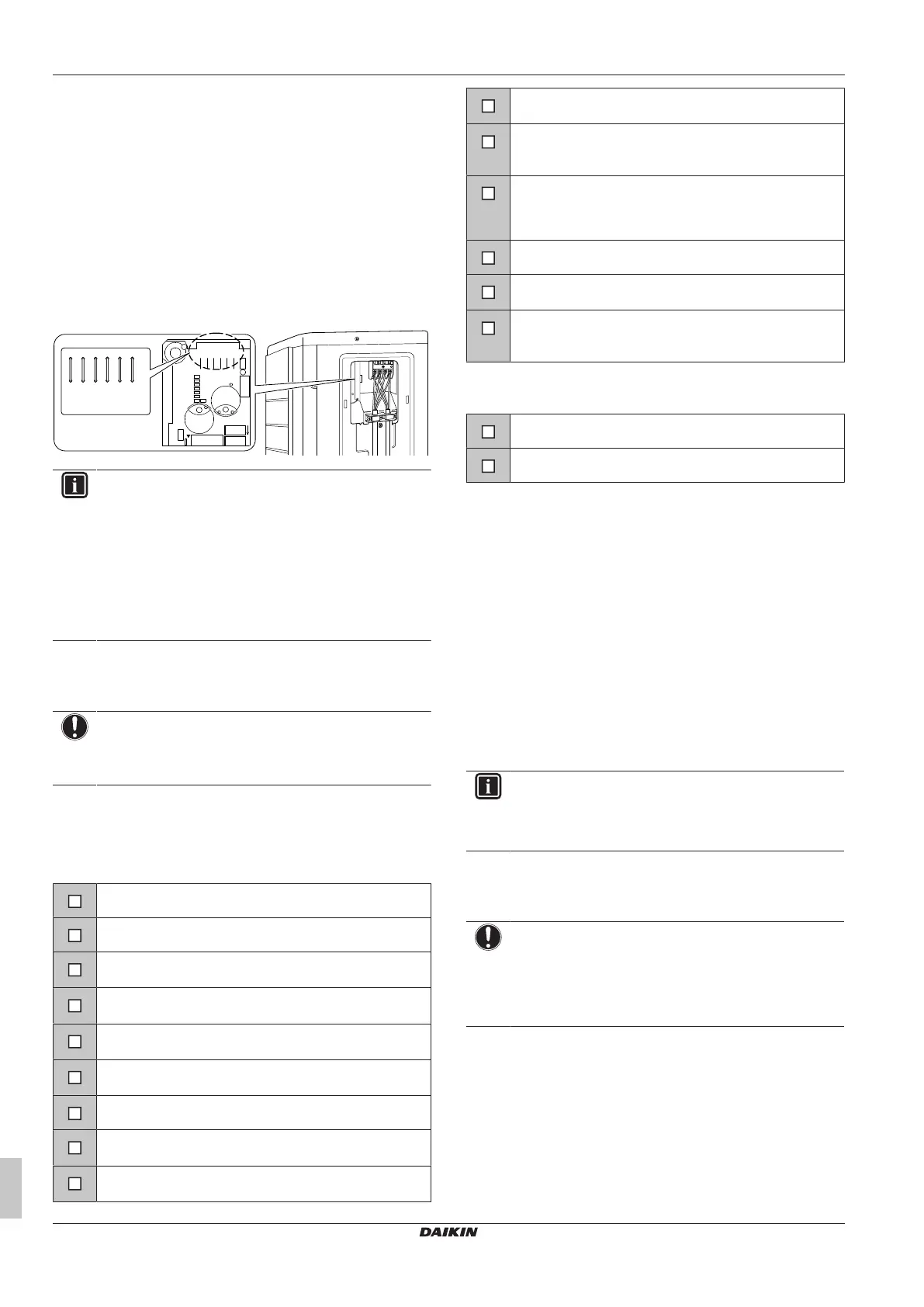

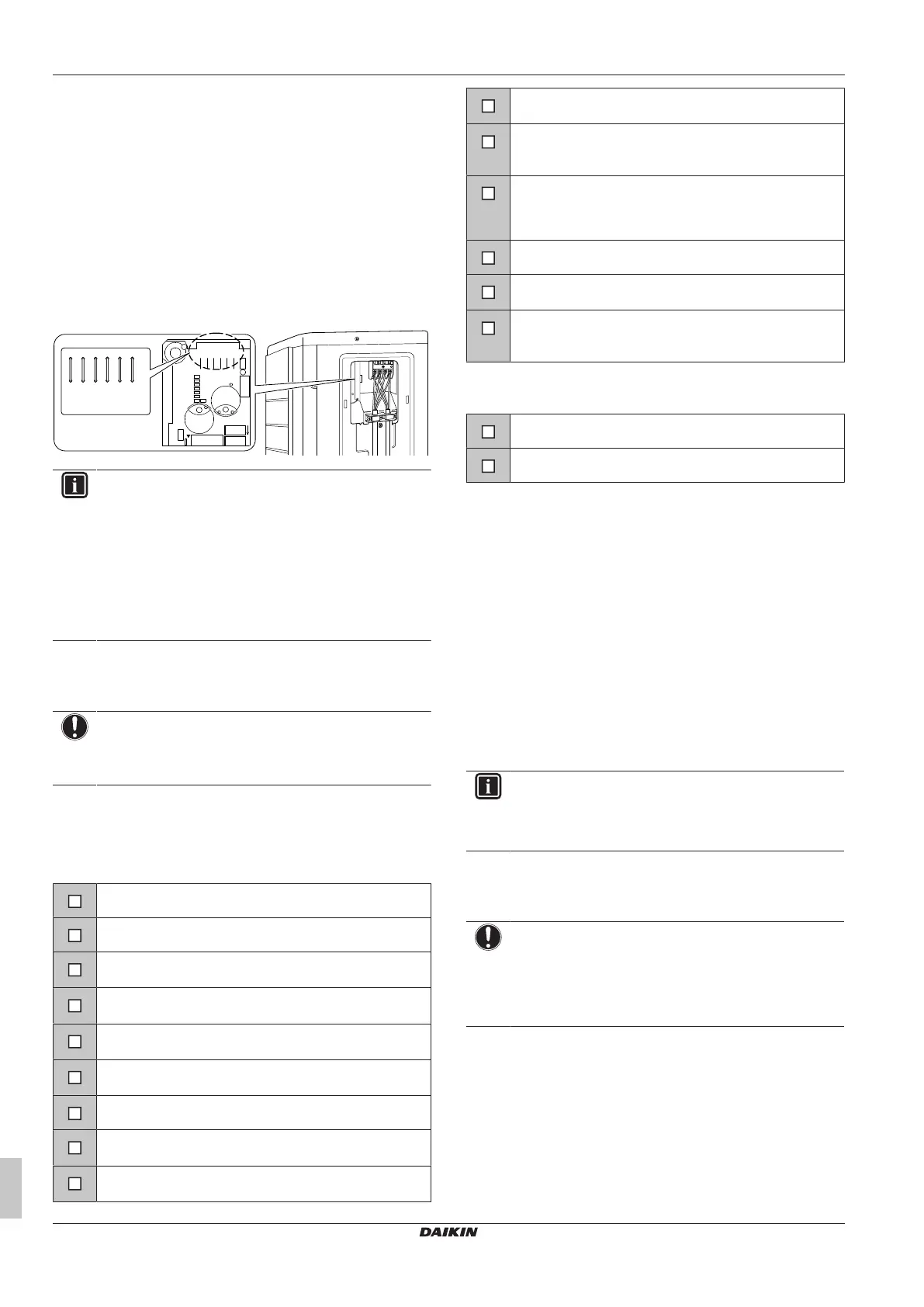

When cutting jumper J6 on the PCB, the operation range will expand

to –15°C. The facility mode will stop if the outdoor temperature drops

below –20°C and resume when the temperature rises again.

1

2

3

J5

J6

J8

J9

J11

J12

+6V

R714

R713

R712

R711

R710

R721

R612

R613

D204

D202

C207

D203

ID201

C211

D206

J12

J11

J9

J8

J6

J5

INFORMATION

▪ The indoor unit may produce Intermittent noise due to

the outdoor unit fan turning ON and/or OFF.

▪ Do NOT place humidifiers or other items which might

raise humidity in rooms when you use the facility mode.

▪ Cutting jumper J6 sets the indoor unit fan to the highest

speed.

▪ Do NOT use this setting in residences or offices with

people.

10 Commissioning

NOTICE

ALWAYS operate the unit with thermistors and/or pressure

sensors/switches. If NOT, burning of the compressor might

be the result.

10.1 Checklist before commissioning

After the installation of the unit, first check the items listed below.

Once all checks are fulfilled, the unit must be closed. Power-up the

unit after it is closed.

The indoor unit is properly mounted.

The outdoor unit is properly mounted.

The system is properly earthed and the earth terminals

are tightened.

The power supply voltage matches the voltage on the

identification label of the unit.

There are NO loose connections or damaged electrical

components in the switchbox.

There are NO damaged components or squeezed

pipes on the inside of the indoor and outdoor units.

There are NO refrigerant leaks.

The refrigerant pipes (gas and liquid) are thermally

insulated.

The correct pipe size is installed and the pipes are

properly insulated.

The stop valves (gas and liquid) on the outdoor unit are

fully open.

The following field wiring has been carried out according

to this document and the applicable legislation between

the outdoor unit and the indoor unit.

Drainage

Make sure drainage flows smoothly.

Possible consequence: Condensate water might drip.

The indoor unit receives the signals of the user interface.

The specified wires are used for the interconnection

cable.

The fuses, circuit breakers, or locally installed protection

devices are installed according to this document, and

have NOT been bypassed.

10.2 Checklist during commissioning

To perform an air purge.

To perform a test run.

10.3 To perform a test run

Prerequisite: Power supply MUST be in the specified range.

Prerequisite: Test run may be performed in cooling or heating

mode.

Prerequisite: Test run should be performed in accordance with the

operation manual of the indoor unit to make sure that all functions

and parts are working properly.

1 In cooling mode, select the lowest programmable temperature.

In heating mode, select the highest programmable temperature.

Test run can be disabled if necessary.

2 When the test run is finished, set the temperature to a normal

level. In cooling mode: 26~28°C, in heating mode: 20~24°C.

3 The system stops operating 3 minutes after the unit is turned

OFF.

INFORMATION

▪ Even if the unit is turned OFF, it consumes electricity.

▪ When the power turns back on after a power break, the

previously selected mode will be resumed.

11 Disposal

NOTICE

Do NOT try to dismantle the system yourself: dismantling

of the system, treatment of the refrigerant, oil and other

parts MUST comply with applicable legislation. Units

MUST be treated at a specialised treatment facility for

reuse, recycling and recovery.

12 Technical data

▪ A subset of the latest technical data is available on the regional

Daikin website (publicly accessible).

▪ The full set of latest technical data is available on the Daikin

Business Portal (authentication required).

Loading...

Loading...