7 | Piping installation

Installer reference guide

39

RXTM30+40N2V1B + RXTP25+35N2V1B9 + RXTP25+35N2V1B8 +

ARXTP25+35N2V1B + RXTA30N2V1B

R32 split series

4P518023-7H – 2020.08

▪ After handling the stop valve, tighten the stem cap, and check for refrigerant

leaks.

Item Tightening torque (N∙m)

Stem cap, liquid side 14.2~17.2

Stem cap, gas side 17.1~20.9

To handle the service cap

▪ ALWAYS use a charge hose equipped with a valve depressor pin, since the service

port is a Schrader type valve.

▪ After handling the service port, tighten the service port cap, and check for

refrigerant leaks.

Item Tightening torque (N∙m)

Service port cap 10.8~14.7

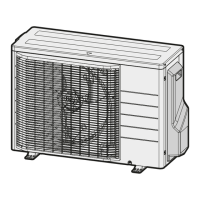

7.2.7 To connect the refrigerant piping to the outdoor unit

▪ Piping length. Keep field piping as short as possible.

▪ Piping protection. Protect the field piping against physical damage.

1 Connect the liquid refrigerant connection from the indoor unit to the liquid

stop valve of the outdoor unit.

a Liquid stop valve

b Gas stop valve

c Service port

2 Connect the gas refrigerant connection from the indoor unit to the gas stop

valve of the outdoor unit.

NOTICE

It is recommended that the refrigerant piping between indoor and outdoor unit is

installed in a ducting or the refrigerant piping is wrapped with finishing tape.

7.3 Checking the refrigerant piping

7.3.1 About checking the refrigerant piping

The outdoor unit's internal refrigerant piping has been factory tested for leaks. You

only have to check the outdoor unit's external refrigerant piping.

Before checking the refrigerant piping

Make sure the refrigerant piping is connected between the outdoor unit and the

indoor unit.

Loading...

Loading...