SiE25-110 RZP71~140D

Removal Procedure 223

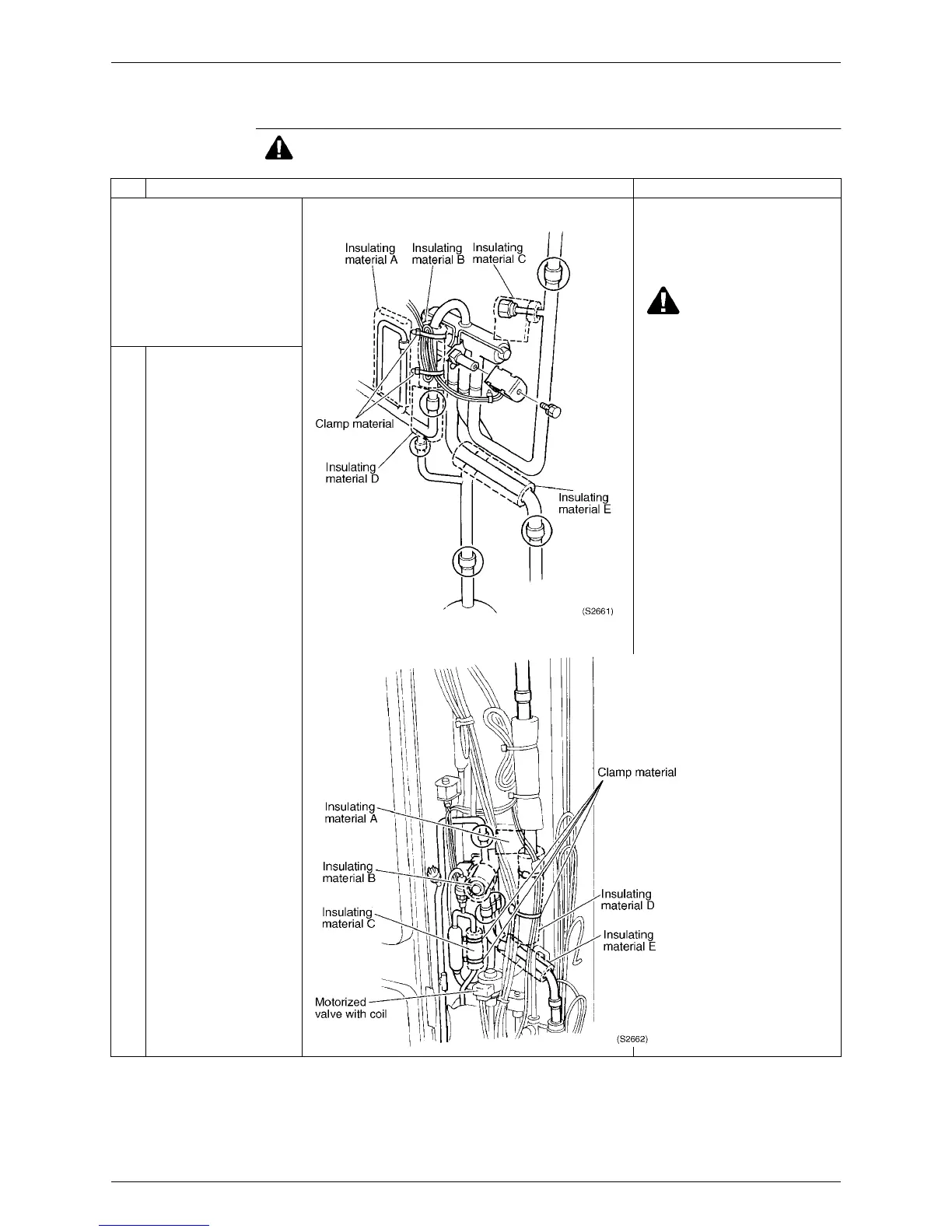

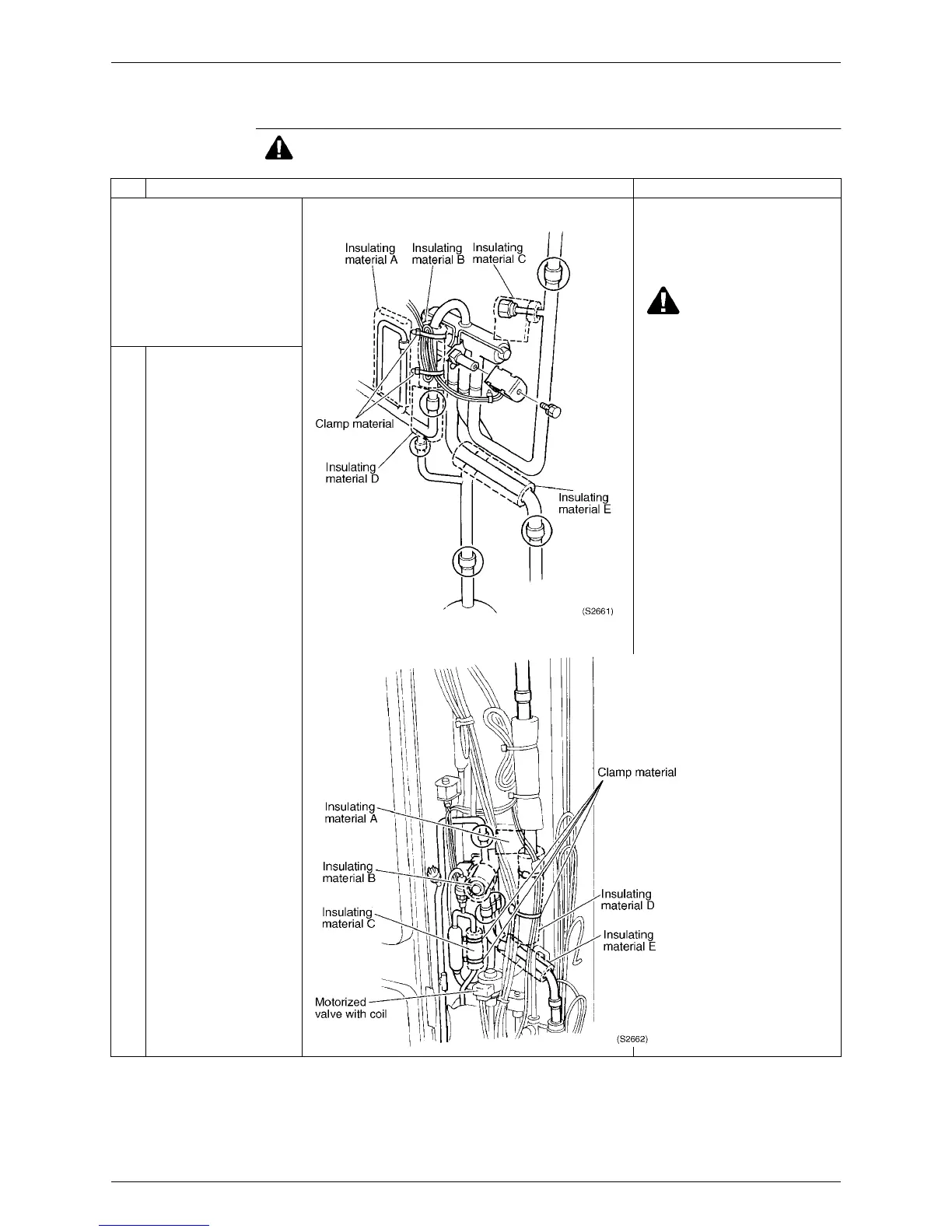

2.8 Removal of Four Way Valve

Procedure Warning Be sure to wait 10 minutes or more after turning off all power supplies

before disassembling work.

Step

Procedure Points

Remove the outside

panels according to the

procedure for removing

outside panels, etc.

Remove the stop valve

mounting plate according

to the procedure for

removing the compressor.

For RZP71D

For RZP100~140D

Make sure that there is no

refrigerant in the unit before

disassembling.

Warning

If the refrigerant gas leaks

during the service work,

ventilate the area. (When the

refrigerant gas contacts

flames, toxic gases may be

generated.)

When welding the pipes,

provide preparation sheets

or iron plates to prevent

flames of gas welder from

contacting other pipes.

Caution

When installing, use wet

cloths to cool the valve and

piping. Do not allow the

temperature of the main unit

to exceed 120˚C or more.

1

Remove the clamp

material securing the

lead wires for four way

valve and solenoid

valve.

2

Remove the 5

insulating materials

(A to E).

3

Remove the 1 screw to

disconnect the four way

valve coil.

4

Disconnect the four way

valve main unit at the 5

brazed sections

(4 brazed sections for

RZP100~140D

models).

Loading...

Loading...