IOM 1207-6 • TRAILBLAZER

®

MODEL AGZ CHILLERS 42 www.DaikinApplied.com

Pump packages may be single or dual pump arrangement.

Each pump is a vertical, in-line, radially split-case pump with a

single spring inside mechanical seal with carbon against silicon

carbide faces. Each case is cast iron. Impellers are bronze,

trimmed to design conditions and then balanced. The shaft

sleeve is bronze, extending the full length of the seal area.

Dual pumps are mounted in a common casing with a

common inlet connection and outlet connection. The pumps

are designed for duty/standby, not parallel operation, and is

capable of having one side running at one time. A apper valve

on the discharge side of the casing is ipped over to the side

by the moving water to prevent recirculation when only one

pump is operating.

The servicing of one side of the pump will require the following:

a. to stop running the pump

b. remove the one rotating head

c. install a gasket and blanking plate on one side of

the pump casing

d. start the pump back up with the one rotating head

and the defective one can be serviced.

For all pump arrangements, each pump is serviceable without

breaking pipe connections. The motor and pump rotating

assembly can be serviced without removing the pump casing

from the line.

All information and performance curves for the single pump

arrangement can be used for the dual pump arrangement.

Pump performance curves are generated by Daikin Tools for

the specic criteria of the installation. Contact a Daikin Applied

representative for this information.

Additional factory provided components:

• “Y” type inlet strainer (shipped loose)

• Combination triple-duty outlet valve having a drip-tight

discharge shuto valve, non-slam check valve, and ow

throttling valve (shipped loose)

• Combination suction guide with ow stabilizing outlet

vanes and stainless steel strainer with a disposable ne-

mesh strainer for start-up

• Factory power and control wiring from the AGZ-E chiller

to the pump package control panel

• Flow switch mounted and wired

• Interconnecting piping with grooved couplings

• Insulation of all cold surfaces

Optional components that may be factory or

eld supplied:

• Water pressure gauges on the pump suction and

discharge

• Expansion tank with size increments from 4.4 to 90

gallons, eld installed (small sizes can be factory

mounted)

• Air separator with air vent, eld installed

• Flex piping connections, eld installed

• Storage tanks - vertical, insulated, (150, 300, 600,

1000 gallon sizes) with optional immersion heater, eld

installed.

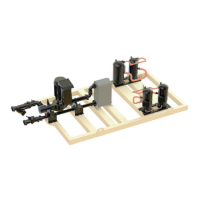

Figure 45: Pump Package Standard Components

Dual Pump Package with Storage Tank

Included with all Pump Packages

1. Wye – Strainer

3. Pump

4. Sucon Guide

7. Heat Exchanger

8. Flow Switch

9. Triple Duty Valve

15.Buerfly Valve

14. Internal to Pu-m p Check Valve s

*Only with dual pumps

Factory Mounted or Field Supplied

2. Expansion Tank

6. Pressure Gauges

Factory or Field Supplied but Field Mounted

5. Air Vent Connecon Port

11. Flex Connecons

13. Air Separator and Vent

Field Supplied and Mounted

10. Pressure Relief

12. Pressure Reducing / Fill Valve

Note: Pump Package insulaon is included

04/30/2007 TDN

07/31/2015 LTN

02/07/2019 DCG

Oponal dual pump shown in diagram

Loading...

Loading...