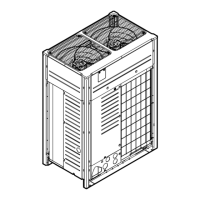

RXYQ72T

RXYQ96-168T

5

6

8

7

4

3

1

6

8

7

3

2

1

2

5

1 Power/ground wires.

2 Clear over 2 in. (50 mm)

3 Transmission wiring

4 Clamp (1) (accessory)

5 Clamp (2)(accessory)

6 Power wiring

7 Transmission wiring

8 Ground wire

Precautions when knocking out knockout holes

r To punch out a knockout hole, hit it with a hammer.

r Open an appropriate hole as needed.

r After knocking out the holes, trim off the burr, then we recommend

you to paint the edges and areas around the edges using the repair

paint to prevent rusting.

r Power line: Open a knockout hole as shown at right and connect it

using a conduit.

Choose an appropriate knockout hole for conduit size suitable for

the power and ground line to be used.

r Transmission line: Connect it using a conduit in the knockout hole

on the left.

Knockout hole (Transmission line) I7/8 in. (22.2 mm)

Knockout hole (Power line)

Burr

I7/8 in. (22.2 mm)

I1-1/8 in. (27.8 mm)

I1-3/8 in. (34.5 mm)

NOTE

r After wiring work is completed, check to make sure there are no

NQQUGEQPPGEVKQPUCOQPIVJGGNGEVTKECNRCTVUKPVJGEQPVTQNDQZ

10. Air tight test and vacuum drying

r #HVGTƂPKUJGFRKRKPIYQTMECTT[QWVCKTVKIJVVGUVCPFXCEWWOFT[KPI

NOTE

r Always use nitrogen gas for the air tightness test.

r Absolutely do not open the stop valve until the main power circuit

insulation measurement has been completed. (Measuring after the

stop valve is opened will cause the insulation value to drop.)

<Needed tools>

Gauge manifold

Charge hose

valve

r To prevent entry of any impurities and insure

UWHƂEKGPVRTGUUWTGTGUKUVCPEGCNYC[UWUGVJG

special tools dedicated for R410A.

r Use charge hose that have pushing stick for con-

necting to service port of stop valves or refriger-

ant charge port.

Vacuum pump

r The vacuum pump for vacuum drying should be

able to lower the pressure to 500 microns.

r 6CMGECTGVJGRWORQKNPGXGTƃQYDCEMYCTFKPVQ

the refrigerant pipe during the pump stops.

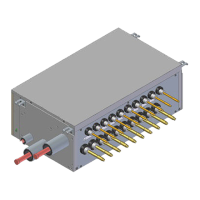

<The system for airtight test and vacuum drying>

r 4GHGTTKPIVQVJGƂIWTGDGNQYEQPPGEVCPKVTQIGPVCPMTGHTKIGTCPV

tank, and a vacuum pump to the outdoor unit.

The refrigerant tank and the charge hose connection to refrigerant

EJCTIGRQTVQTVJGXCNXG#KPVJGƂIWTGDGNQYCTGPGGFGFKP

%JCTIKPITGHTKIGTCPVQPRCIG|

1

23

4

5

11

13

12

14

15

A

7

1 Pressure reducing valve

2 Nitrogen

3 Measuring instrument

4 Refrigerant R410A tank (siphon system)

5 Vacuum pump

6 Charge hose

7 Refrigerant charge port

8 Gas line stop valve

9 Liquid line stop valve

10 Outdoor unit

11 To indoor unit

12 Stop valve

13 Field piping

14 )CUƃQY

15 Stop valve service port

A Valve A

B Valve B

C Valve C

NOTE

r The air-tightness test and vacuum drying should be done using the

service ports of equalizer pipe, gas pipe and liquid pipe stop valve.

See the [R410A] Label attached to the front panel of the outdoor

WPKVHQTFGVCKNUQPVJGNQECVKQPQHVJGUGTXKEGRQTV5GGVJGƂIWTG

below).

Loading...

Loading...