RXYQ72T RXYQ96-168T

[R410A] Label

[R410A] Label

r 5GG/GVJQFHQTCFFKPITGHTKIGTCPVQPRCIG|HQTFGVCKNUQP

handling the stop valve.

r The refrigerant charge port is connected to unit pipe. When

shipped, the unit contains the refrigerant, so use caution when at-

taching the charge hose.

<Air tight test>

Pressurize the liquid pipe, gas pipe, and equalizer pipe from the ser-

XKEGRQTVUQHGCEJUVQRXCNXGVQRUK|/2CFQPQVRTGUUWTK\G

OQTGVJCPRUK|/2C+HVJGRTGUUWTGFQGUPQVFTQRYKVJKP

hours, the system passes the test.

If there is a pressure drop, check for leaks, make repairs and perform

the air tight test again.

<Vacuum drying>

'XCEWCVGVJGU[UVGOHTQOVJGNKSWKFRKRGCPFICURKRGUVQRXCNXGUGT-

vice ports by using a vacuum pump for more than 2 hours and bring

the system to 500 microns or less. After keeping the system under that

condition for more than 1 hour, check if the vacuum gauge rises or not.

If it rises, the system may either contain moisture inside or have leaks.

NOTE

During the rainy season, moisture might enter the piping. If

working during a rainy season and the work takes long enough

for condensation to form inside the pipes, take the following

precautions:

After evacuating the system for 2 hours, pressurize the system to

|RUK|/2CXCEWWODTGCMYKVJPKVTQIGPICUCPFGXCEWCVG

the system again using the vacuum pump for 1 hour to 500 microns or

less (vacuum drying).

+HVJGU[UVGOECPPQVDGGXCEWCVGFVQOKETQPUYKVJKP|JQWTU

repeat the operation of vacuum break and vacuum drying.

6JGPCHVGTNGCXKPIVJGU[UVGOKPCXCEWWOHQTJQWTEQPƂTOVJCVVJG

vacuum gauge does not rise.

11. Pipe insulation

r Insulation of pipes should be done after performing 10. Air tight test

CPFXCEWWOFT[KPIQPRCIG|

r Always insulate the liquid piping, the gas piping, the equalizer pipes

(between the outdoor units for the outdoor multi system) and pipe

connections.

r Failing to insulate the pipes may cause leaking or burns.

Be sure to use insulation designed for HVAC equipment.

r Reinforce the insulation on the refrigerant piping according to the

installation environment. Condensation might form on the surface of

the insulation. Refer to the below.

- Ambient temperature : 86°F (30°C), humidity : 75% to 80% RH :

minimum thickness : 9/16 in. (15 mm).

- +HVJGCODKGPVVGORGTCVWTGGZEGGFU(%CPFVJGJWOKFKV[

80% RH, then the minimum thickness is 3/4 in. (20 mm).

5GGVJG'PIKPGGTKPIFCVCDQQMHQTFGVCKN

r If there is a possibility that condensation on the stop valve might

drip down into the indoor unit through gaps in the insulation and

piping because the outdoor unit is located higher than the indoor

unit, this must be prevented by caulking the connections. (Refer to

VJGHQNNQYKPIƂIWTG

1

2

1

5

3

4

1 Insulation material

2 Caulking, etc.

3 Liquid pipe stop valve

4 Gas pipe stop valve

5 Connection pipe

12. Checking of device and installation conditions

Be sure to check the followings.

For those doing electrical work

1 Make sure there is no faulty transmission wiring or loosening of a

nut.

5GG6TCPUOKUUKQPYKTKPIEQPPGEVKQPRTQEGFWTGQPRCIG|

2 Make sure there is no faulty power wiring or loosening of a nut.

5GG2QYGTYKTKPIEQPPGEVKQPRTQEGFWTGQPRCIG|

3 Has the insulation of the main power circuit deteriorated?

Measure the insulation and check the insulation is above regular

value in accordance with relevant local and national regulations.

For those doing pipe work

1 Make sure piping size is correct.

5GG5GNGEVKQPQHRKRKPIOCVGTKCNQPRCIG|CPF5GNGE-

VKQPQHTGHTKIGTCPVDTCPEJMKVUQPRCIG|

2 Make sure insulation work is done.

See 11. Pipe insulation.

3 Make sure there is no faulty refrigerant piping.

5GG2TGECWVKQPUQPTGHTKIGTCPVRKRKPIQPRCIG|

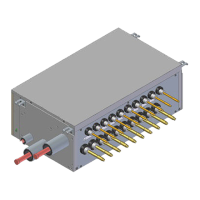

13. /CMKPIƂGNFUGVVKPIU

6QEQPVKPWGVJGEQPƂIWTCVKQPQHVJG848+8JGCVRWORU[UVGOKVKU

required to give some input to the logic board of the unit. This chapter

will describe how manual input is possible by operating the push but-

tons/DIP switches on the logic board and reading the feedback from

the 7 segment displays.

Loading...

Loading...