17

180R9267 / IOM APP 1.5-3.5 Appendices - v04 / 11.2013

Instruction APP pump instruction APP 0.6-1.0, APP 1.5-2.5 and APP 3.0-3.5

4

180R9065 / 521B0733 / DKCFN.PI.013.C4.2T / 09.2012

2.4 General guidelines for calculation of

pressure losses

In order to avoid the risk of cavitation, the inlet

pressure at the pump must be in accordance

with the specifications mentioned in Data

sheet (521B0850).

The inlet line connection must be properly

tightened, as possible entrance of air will cause

cavitation.

The suction conditions can be optimized

according to below guidelines.

2.5 General comments on

Filtration

A good filtration is vital to ensure a long and

trouble free life of the pump.

When selecting a lter or strainer, please note

that lter materials should be compatible with

water, i.e. should neither corrode or dissolve. Also

be aware of the electrochemical series of the

applied materials.

Main lter must have a neness of 10 μm abs.

ß 10 >5000. The pressure loss across the lter

should be monitored.

Water tank

Must be made of corrosion-proof material such

as stainless steel or plastic and must be sealed to

prevent entrance of impurities from the environ-

ment.

In smooth pipes and hoses

In 90° bends

In smooth pipes and hoses

Instruction APP pump instruction APP 0.6-1.0, APP 1.5-2.5 and APP 3.0-3.5

5

180R9065 / 521B0733 / DKCFN.PI.013.C4.2T / 09.2012

3. Building up the pump

unit

Automatic pressure equalization between tank

and surroundings must be ensured.

Inlet from the water supply and inlet to the

pump should be placed in opposite ends of the

tank to calm and deaerate the water, and to

ensure optimum opportunity for particles to

settle.

Pump suction line should be placed relatively

high above the tank bottom in order to prevent

settled particles from being led into the pump.

We recommend a separation (“wall”) to separate

the inlet from the outlet end of the tank.

Monitoring

It is recommended to continuously monitor the

following conditions:

• Water level in the tank

• Filter contamination

• Pressure (inlet- and outlet side of the

pump)

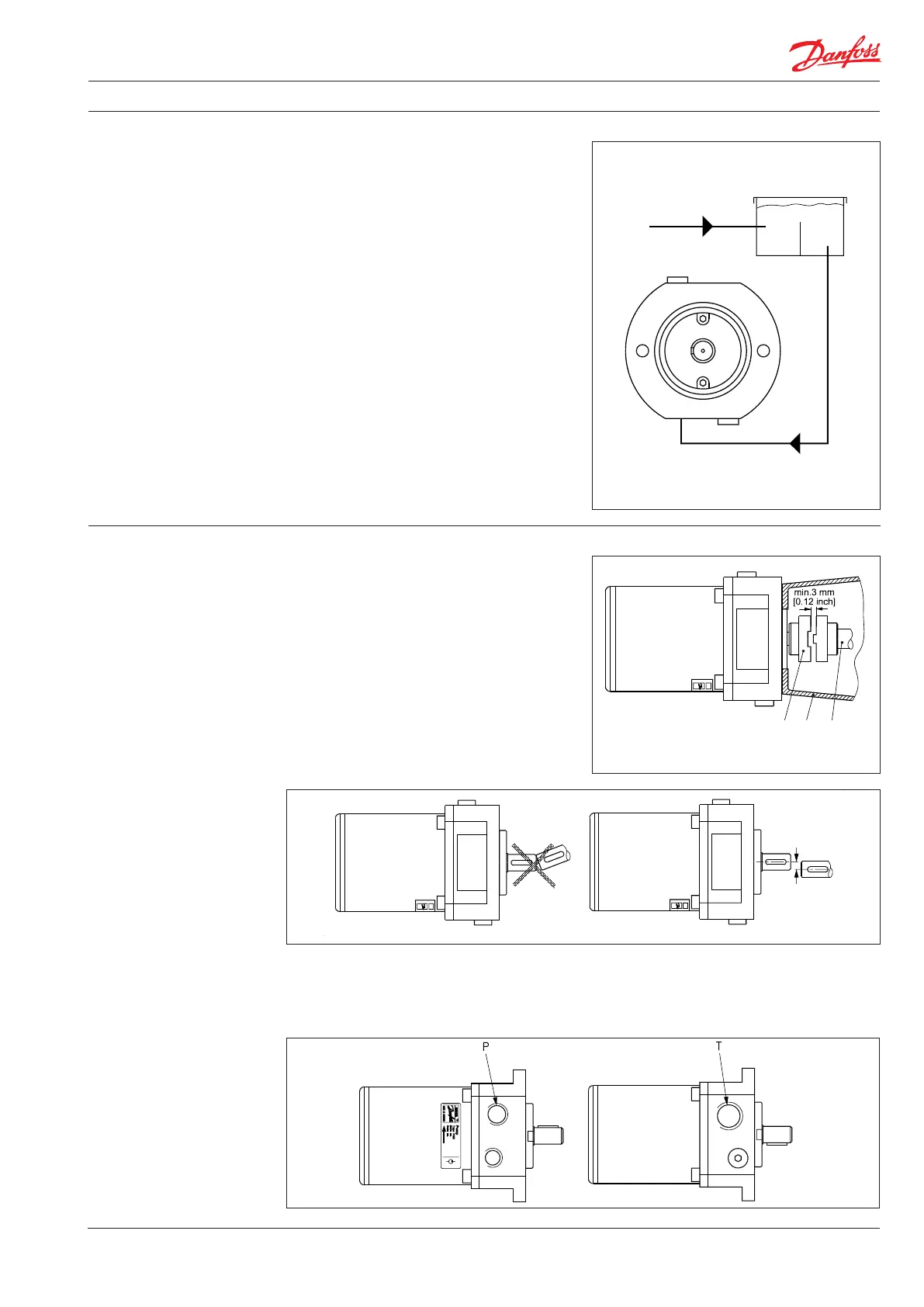

3.1 Mounting

(Please also see hints in “Right and Wrong”)

If alternative mounting is desired, please contact

the Danfoss Sales Organization.

Choose proper tolerances to ensure an easy

mounting of the elastic coupling without use of

tools.

Please take care to observe the recommended

length tolerances of the chosen coupling, as an

axial force on the pump will damage the pump.

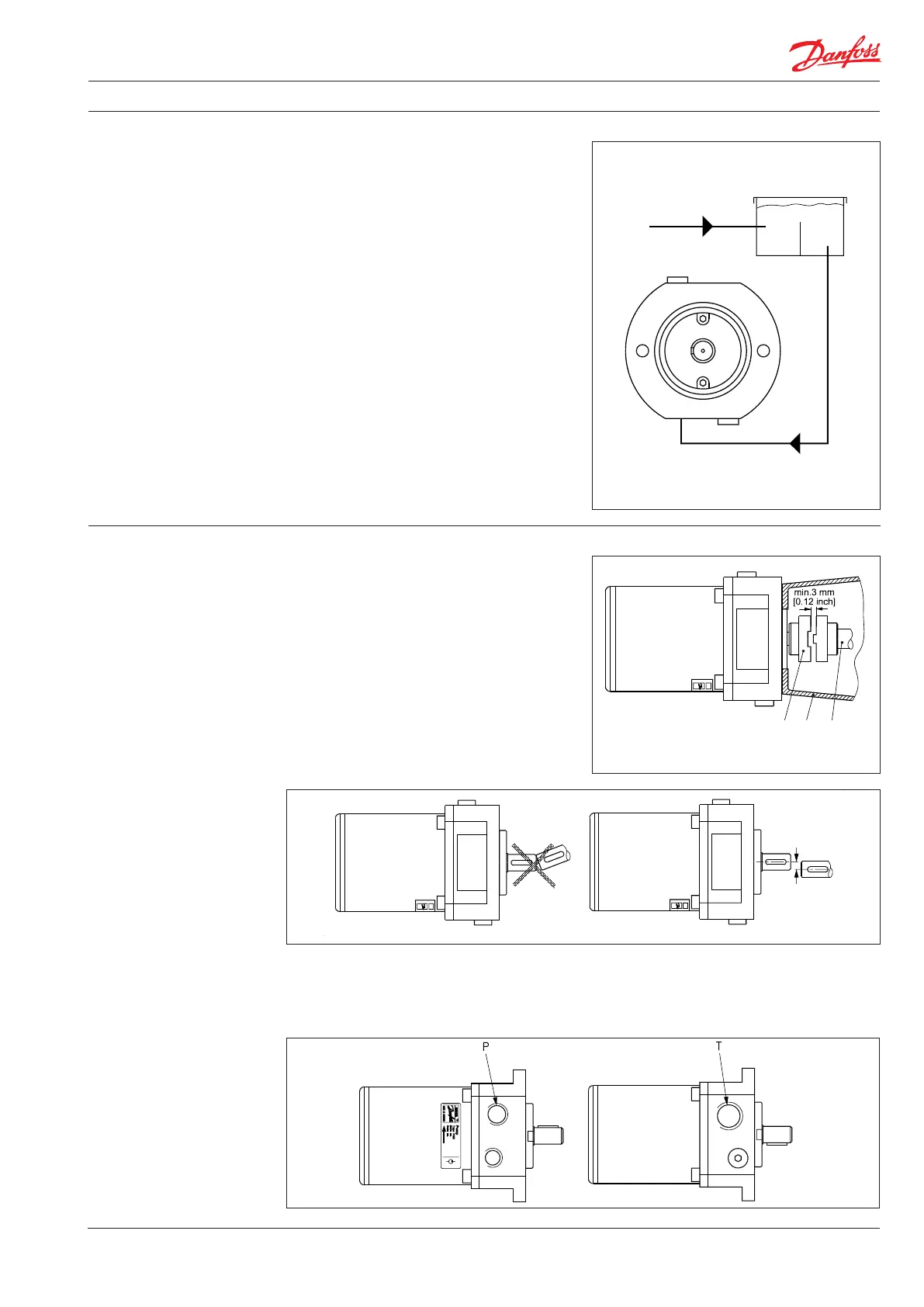

3.2 Direction of rotation

Is indicated by means of an arrow at the inlet side

of the pump.

P Outlet

T Inlet

max. 0.25 mm

max. 0.01 inch

A Elastic coupling

B Ball housing

C Motor shaft

A B C

Loading...

Loading...