2 Instructions RI8NG552 © Danfoss 10/2011 EKC 326A

0 V = ventil lukket, Valve closed, Ventil geschlossen, Vanne fermée

10 V = ventil åben Valve open Ventil offen Vanne ouverte

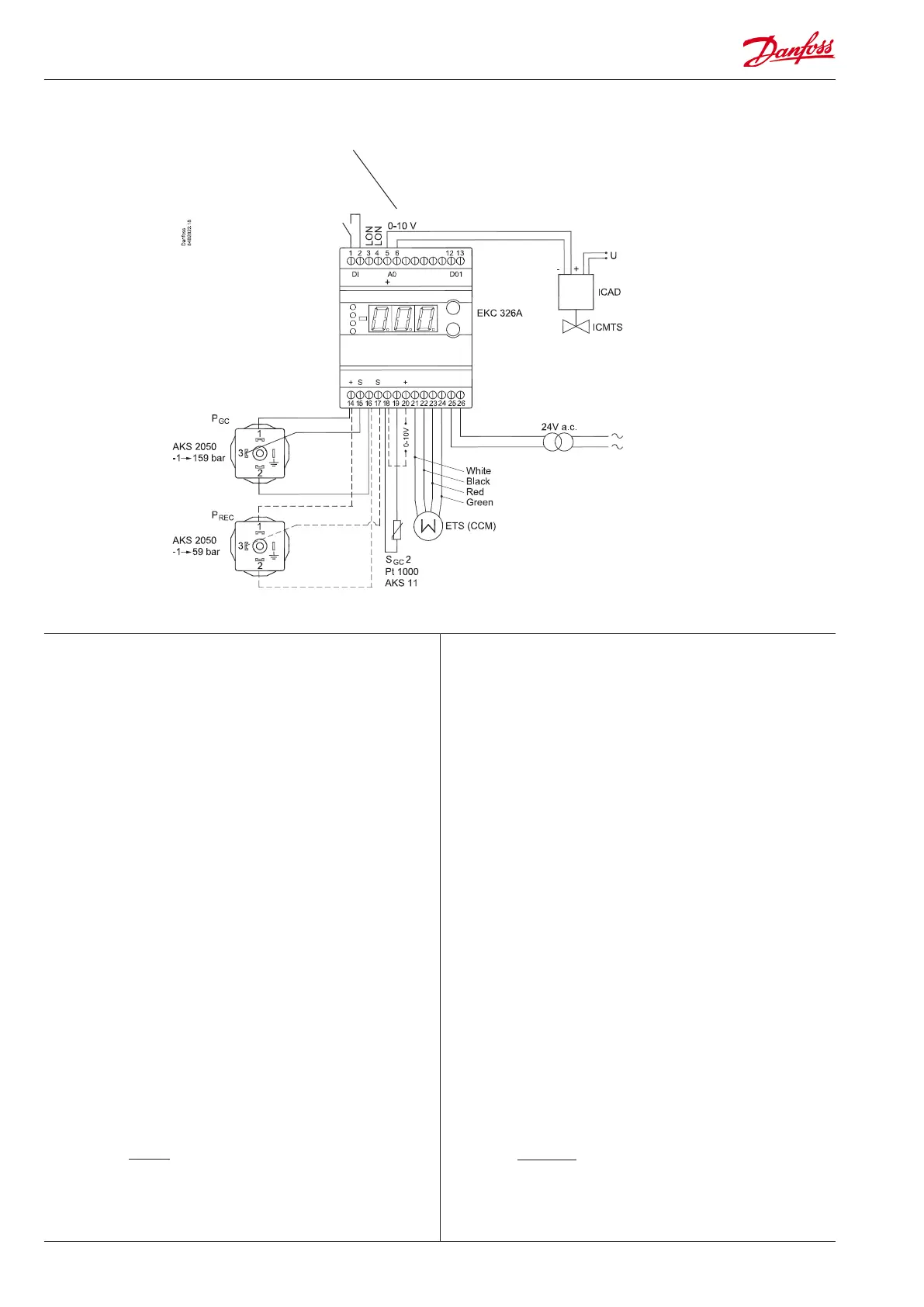

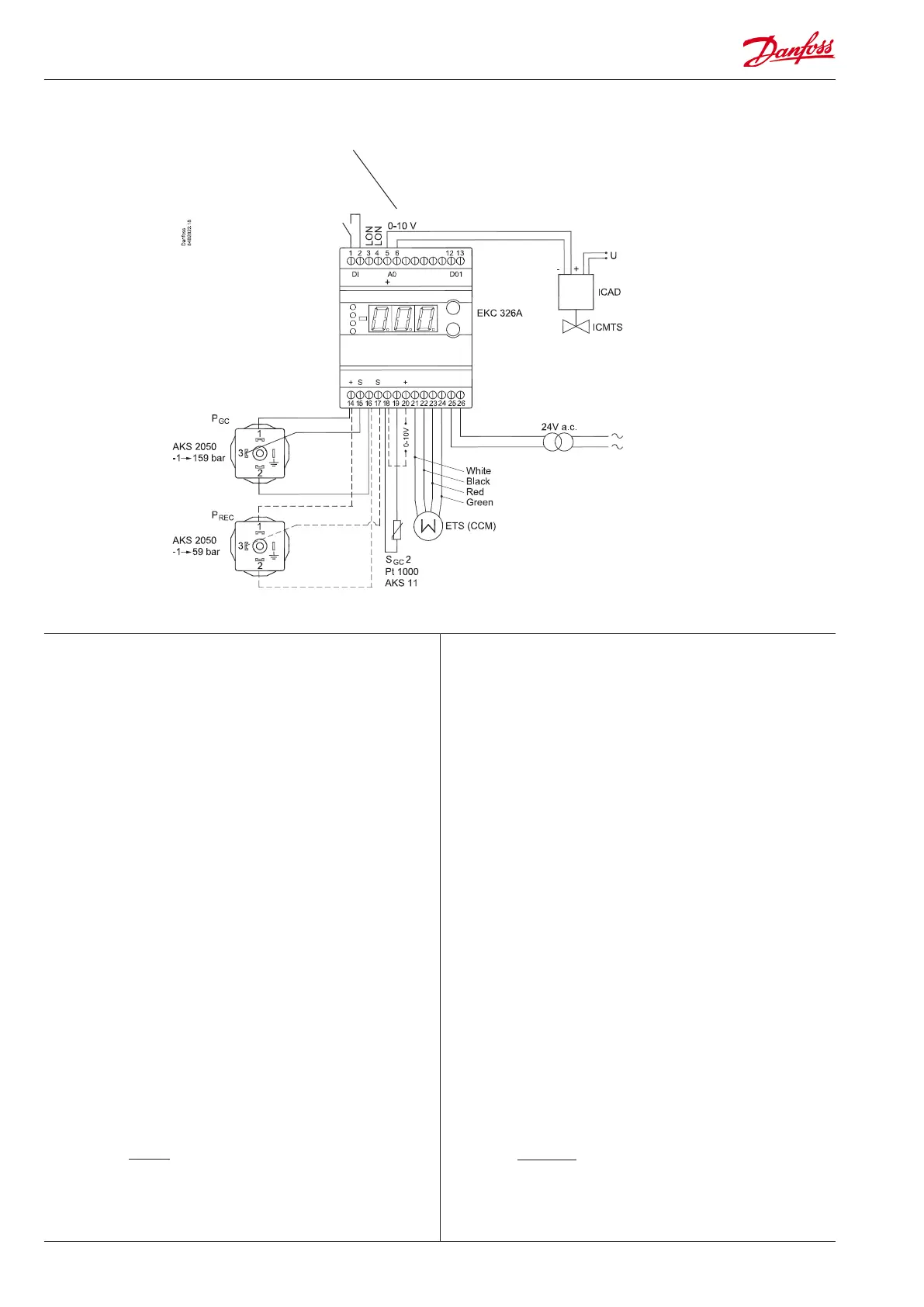

Necessary connections

Terminals:

25-26 Supply voltage 24 V a.c.

18-19 Pt 1000 sensor at gas cooler outlet (S

GC

2

)

14,15,16 Pressure transmitter AKS 2050, -1 to 159 bar

To register the correct pressure it must be mounted as

close as possible to the gas cooler.

5-6 Voltage output to control the ICMTS valve.

Application dependent connections

Terminals:

1-2 DI-input to either:

• External main switch (see o02 and r12)

OR

Contact function for increasing capacity (optimised COP

operation stopped). (see o02)

Open connection = optimised COP operation

Closed connection = extra capacity.

12-13 Alarm relay

There is connection between 12 and 13 in alarm situa tions

14,16,17 Optional. A pressure transmitter can be connected so

that the pressure in the receiver can be monitored. The

pressure transmitter must be an AKS 2050, -1 to 59 bar.

21-24 If receiver pressure is to be controlled, a CCM or ETS valve

should be connected.

18-20 Heat recovery. A voltage signal between 2 and 10 V will

increase the gas pressure reference.

3-4 Data communication

Mount only, if a data communication module has been

mounted.

It is important that the installation of the data communi-

cation cable be done correctly. Cf. separate literature No.

RC8AC...

Important

PGC and SGC2 must be mounted near the gas cooler outlet to produce

a correct signal.

High pressure valve

Vhp

Gas bypass valve

Vgbp

8 VA

DANSK

ENGLISH

Tilslutninger

Connections

Nødvendige tilslutninger

Klemme:

25-26 Forsyningsspænding 24 V a.c.

18-19 Pt 1000 føler ved gaskølerafgang (S

GC

2

)

14,15,16 Tryktransmitter type AKS 2050, -1 til 159 bar

For at registrere det korrekte tryk skal den monteres så

tæt ved gaskøleren som muligt.

5-6 Spændingsudgang til styring af ICMTS ventil.

Applicationbestemte tilslutninger

Klemme:

1-2 DI-indgang til enten:

• Ekstern hovedafbryder (se o02 og r12)

ELLER

Kontaktfunktion til hævning af kapaciteten (optimeret

COP-drift stoppes) (se o02).

Åben forbindelse = optimeret COP-drift

Sluttet forbindelse = extra kapacitet.

12-13 Alarmrelæet

Der er forbindelse imellem 12 og 13 i alarmsituationer.

14,16,17 Optional. Der kan tilsluttes en tryktransmitter, så trykket

i receiveren kan følges. Tryktransmitteren skal være en

AKS 2050, -1 til 59 bar.

21-24 Hvis trykket i receiveren skal reguleres, skal der tilsluttes

en ventil type CCM eller ETS.

18-20 Varmegenvinding. Et spændingssignal på 2-10 V vil hæve

gastryksreferencen.

3-4 Datakommunikation

Monteres kun, hvis der også er monteret et datakommuni-

kationsmodul.

Det er vigtigt, at installationen af datakommunikations-

kablet udføres korrekt.

Se separat litteratur nr. RC8AC...

Vigtigt

PGC og SGC2 skal monteres tæt ved gaskølerens afgang for at give

korrekt signal.

Cable connection

060G1034

14 = black

15 = brown

16 = blue

AKS 11: Max. 100°C

AKS 21: Max. 180°C

L > 5 m => AKA 211. Se manual

L > 5 m => AKA 211. See manual

L > 5 m => AKA 211. Siehe Manual

L > 5 m => AKA 211. Voir manual

<-------max. 5 m ---------------->

Loading...

Loading...