Instructions

DEN-GT

VI.CW.C1.02 / LUK40110 © Danfoss 04/2011

9

Termix VMTD-F-B - substation for direct HE and DHW

Troubleshooting DHW

We recommend that troubleshooting be carried

out only by authorized personnel.

In the event of operating disturbances, the following

basic features should be checked before carrying

out actual troubleshooting:

- the substation is connected to electricity,

- the strainer on the DH supply pipe is clean,

- the supply temperature of the DH is at the

normal level (summer, at least 60 °C -

winter, at least 70 °C),

- the differential pressure is equal to or higher

than the normal (local) differential pressure in

the DH network – if in doubt, ask the DH plant

supervisor,

- pressure on the system - check the HE pressure

gauge.

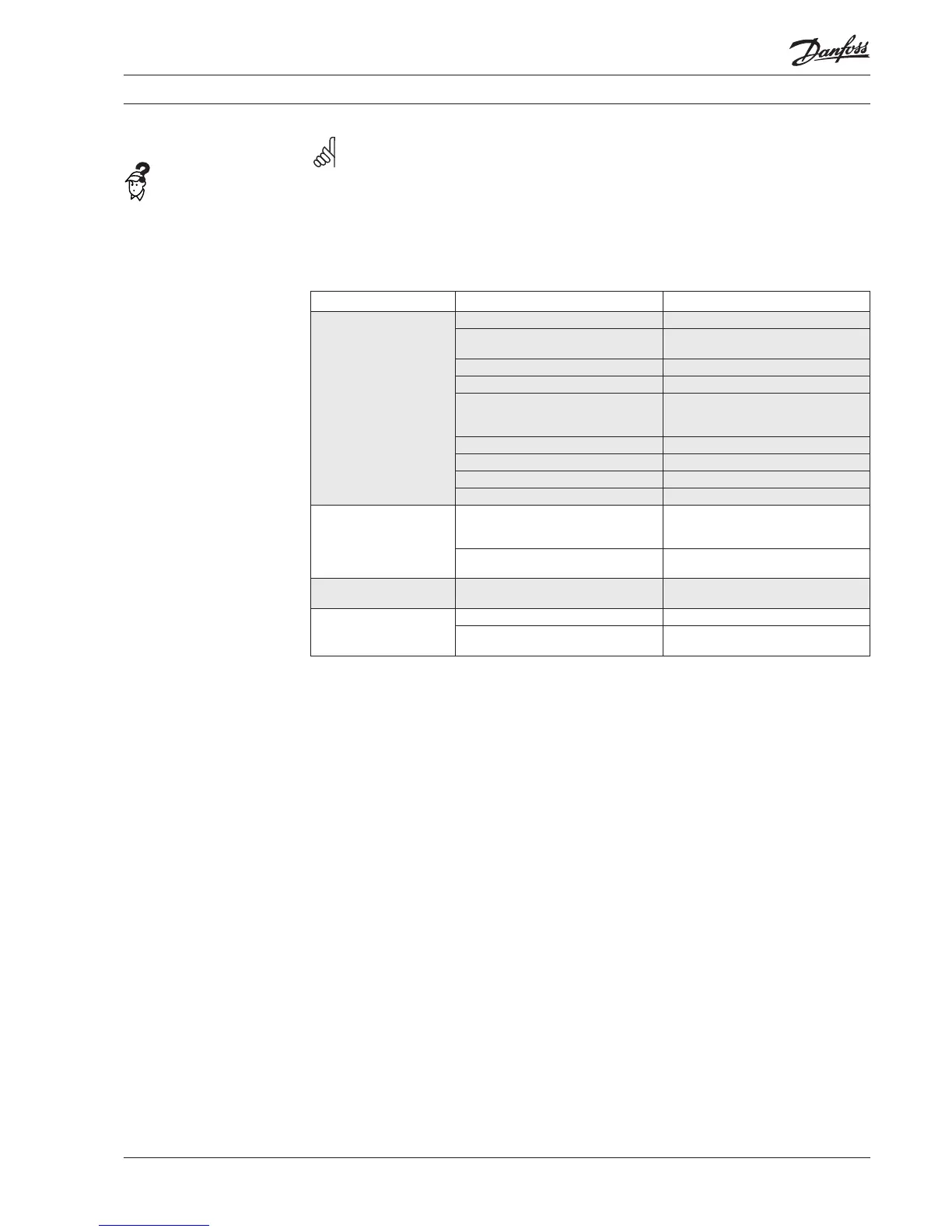

Problem Possible cause Solution

Too little or no DHW

Strainer in supply or return line clogged. Clean strainer(s).

DHW circulation pump out of order or

with setting too low.

Check circulation pump.

Defective or clogged non-return valve. Replace – clean.

No electricity. Check.

Wrong setting of automatic controls,

if any.

To adjust an electronic controller for

DHW, pls. note enclosed instructions for

electronic controller.

Scaling of the plate heat exchanger. Replace – rinse out.

Defective motorized valve. Check (use manual function) - replace.

Defective temperature sensors. Check – replace.

Defective controller. Check – replace.

Hot water in some taps but

not in all.

DCW is being mixed with the DHW, e.g.

in a defective thermostatic mixing valve

or non

Check – replace.

Defective or clogged non-return valve

on circulation valve.

Replace – clean.

Tap temperature too high;

DHW tap load too high.

Thermostatic valve adjusted to a too

high level.

Check - set

Temperature drop during

tapping.

Scaling of the plate heat exchanger. Replace – rinse out.

Larger DHW flow than the substation

has been designed for.

Reduce DHW flow.

Loading...

Loading...