Page 33 of 108

M-AP-001-EN Rev. N

General Specications

• Compressor - Semi-hermetic design

• Main Housing - Dimensionally-stabilized aluminum

• Covers - High-impact, UV stabilized, flame-resistant polymer.

• Covers - High-impact, UV stabilized, flame- resistant polymer. TG series is identified

by green cover.

• Shaft - High-strength alloy

• Impellers - High-strength aluminum

• Motor - Permanent magnet, synchronous, DC

• Bearings - Integrated, digitally-controlled, magnetic

• Compressor Control - Integrated, digital capacity control

• Enclosure - IP54 rating as per UL 984 requirement

5.1 Construction

5 General Specifications

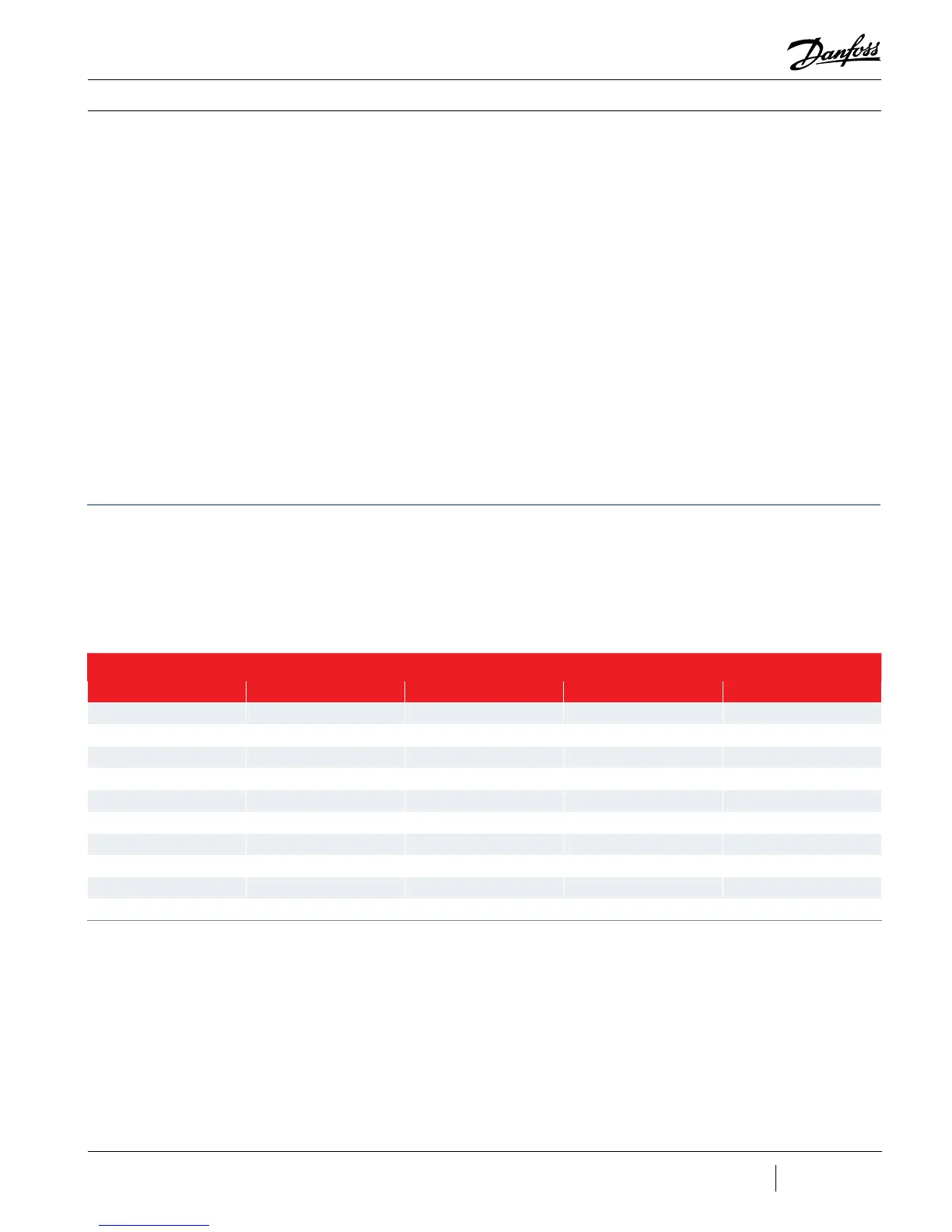

* The TG230/TT300 compressors, the alarm and trip settings are default to lower values of operation which are

typcially deemed appropriate for Water-Cooled condiitons.

These values allow for adjustment for compressors placed in Air-Cooled applications which can have the value

increased up to 1730 kPa(g)/250 PSIG for the Alarm and 1800 kPa(g)/260 PSIG for the Trip.

Table 5-1 - Discharge

Pressure Alarm and Trip

Settings

Model kPa(g) PSIG kPa(g) PSIG

TG230ST* 1239 180 1299 188

TG230MT* 1116 162 1176 171

TG310 1240 180 1300 189

TG390 876 127 926 134

TG520 876 127 926 134

TT300ST* 1190 173 1240 180

TT300MT* 1190 173 1240 180

TT350 1730 251 1800 261

TT400 1190 173 1240 180

TT700 1190 173 1240 180

Alarm Trip

The maximum pressure that the compressor can operate is regulated directly by two control

settings: (1) Alarm Limit and (2) Trip Limit. It is also controlled by a Pressure Ratio alarm limit

monitoring the ratio between the Discharge and Suction Pressures.

5.2 Maximum Pressure

Loading...

Loading...