VLT

®

FCD Series

(boost) at start to disengage the mechanical brake.

To achieve this parameters 130 Start frequency and

131 Initial voltage are used.

Description of choice:

Set the required start frequency. It is a precondition

that parameter 121 Start function, is set to Start fre-

quency/voltage clockwise [3] or Start frequency

voltage in reference direction [4] and that in parame-

ter 120 Start delay a time is set and a reference

signal is present.

131

131 Initial voltage

(INITIAL VOLTAGE)

Value:

0.0 - 200.0 V

✭ 0.0 V

Function:

Initial voltage is active for the time set in parameter

120 Start delay, after a start command. This param-

eter can be used for example for lifting/dropping

applications (conical anchor motors).

Description of choice:

Set the required voltage necessary to cut out the

mechanical brake. It is assumed that parameter 121

Start function, is set to Start frequency/voltage clock-

wise [3] or Start frequency/voltage in reference

direction [4] and that in parameter 120 Start delay a

time is set, and that a reference signal is present.

132

132 DC brake voltage

(DC BRAKE VOLTAGE)

Value:

0 - 100% of max. DC brake voltage

✭ 0%

Function:

In this parameter, the DC brake voltage is set which

is to be activated at stop when the DC brake

frequency set in parameter 127 DC brake cut-in fre-

quency is reached, or if DC braking inverse is active

via a digital input or via serial communication. Sub-

sequently, the DC brake voltage will be active for the

time set in parameter 126 DC brake time.

Description of choice:

To be set as a percentage value of the max. DC

brake voltage, which depends on the motor.

133

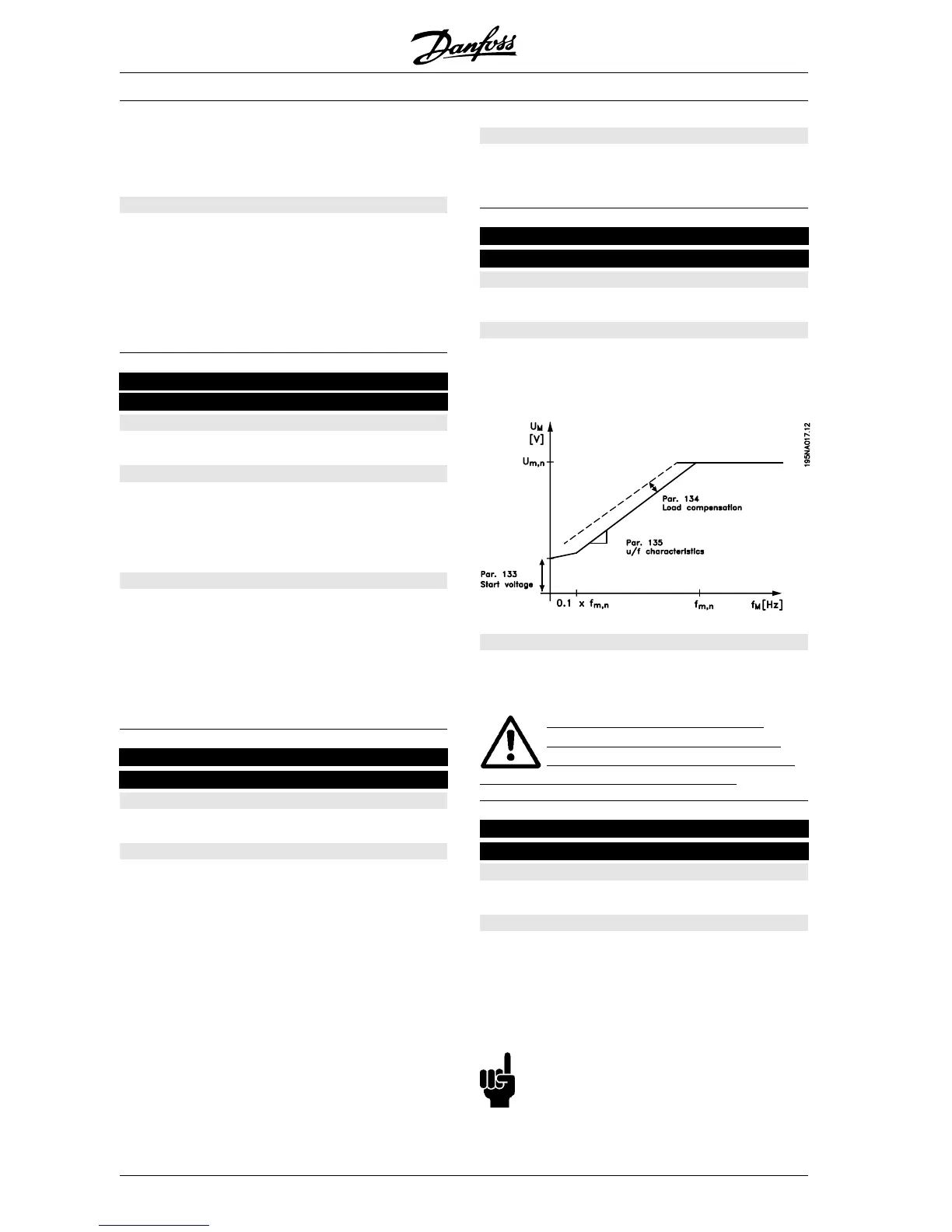

133 Start voltage

(START VOLTAGE)

Value:

0.00 - 100.00 V

✭ Depends on unit

Function:

A higher start torque can be obtained by increasing

the start voltage. Small motors (< 1.0 kW) normally

require a high start voltage.

Description of choice:

The factory setting will be suitable for must applica-

tions, the value may need to be increase gradually

for high torque application.

W

arning: If the use of start voltage

i

s exaggerated, this may lead to over-

e

nergizing and overheating of the motor

and the frequency converter may cut out.

134

134 Load compensation

(LOAD COMPENSATIO)

Value:

0.0 - 300.0%

✭ 100.0%

Function:

In this parameter, the load characteristic is set. By

increasing the load compensation, the motor is given

an extra voltage and frequency supplement at

increasing loads. This is used e.g. in motors/applica-

tions in which there is a big difference between the

full-load current and idle-load current of the motor.

NB!:

If this value is set too high, the frequency

converter may cut out because of overcurrent.

✭

= factory setting. () = display text [] = value for use in communication via serial communication port

MG.04.A1.02 - VLT is a registered Danfoss trade mark

62

Loading...

Loading...