Danfoss Drives, Ulsnaes 1, DK-6300 Graasten, Denmark, Tel. +45 74 88 22 22, Fax +45 74 65 25 80, www.danfoss.com/drives • E-mail: info@danfoss.com

MF004A02 VLT® is a trademark of Danfoss A/S Produced by KKM 2007.10

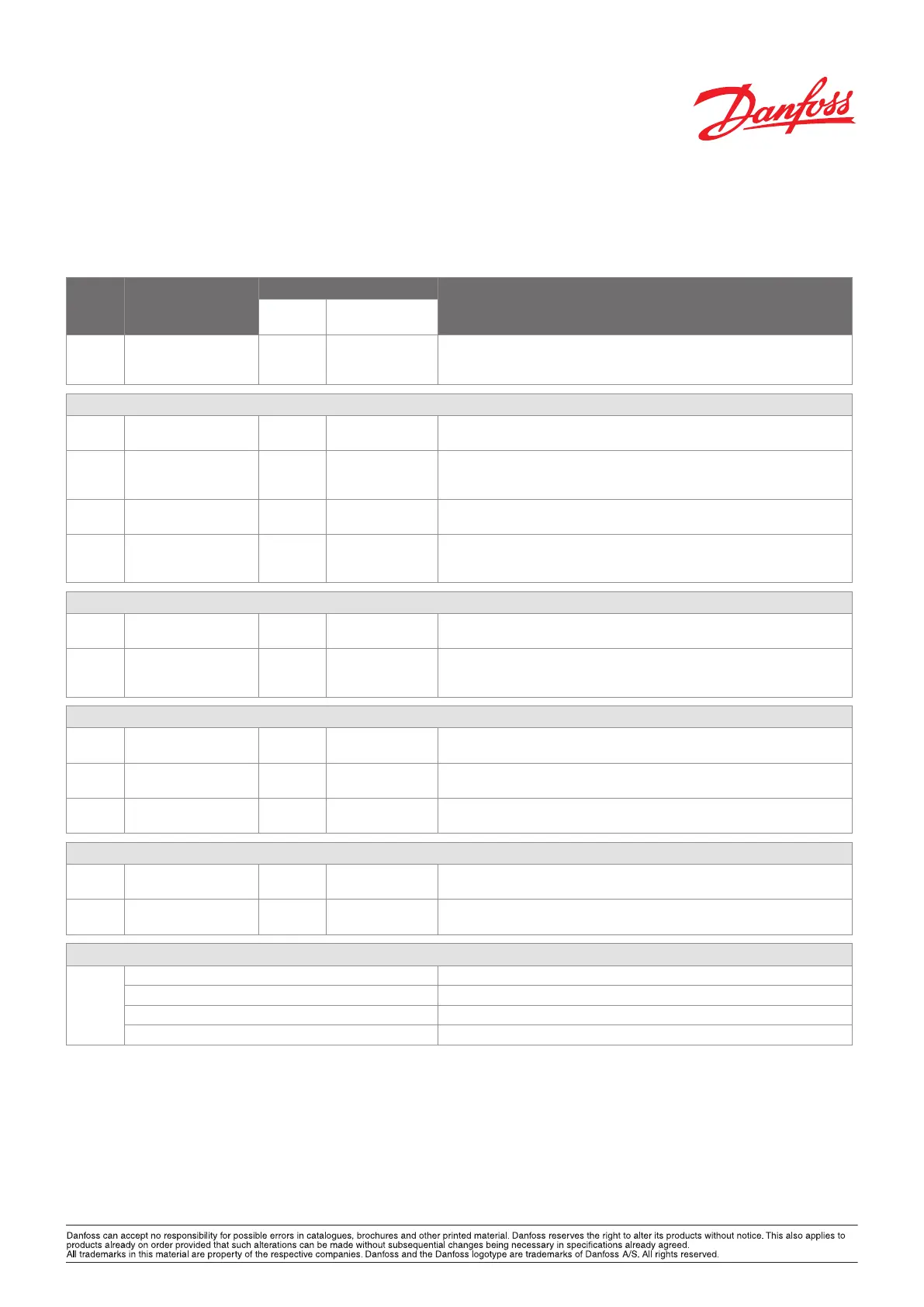

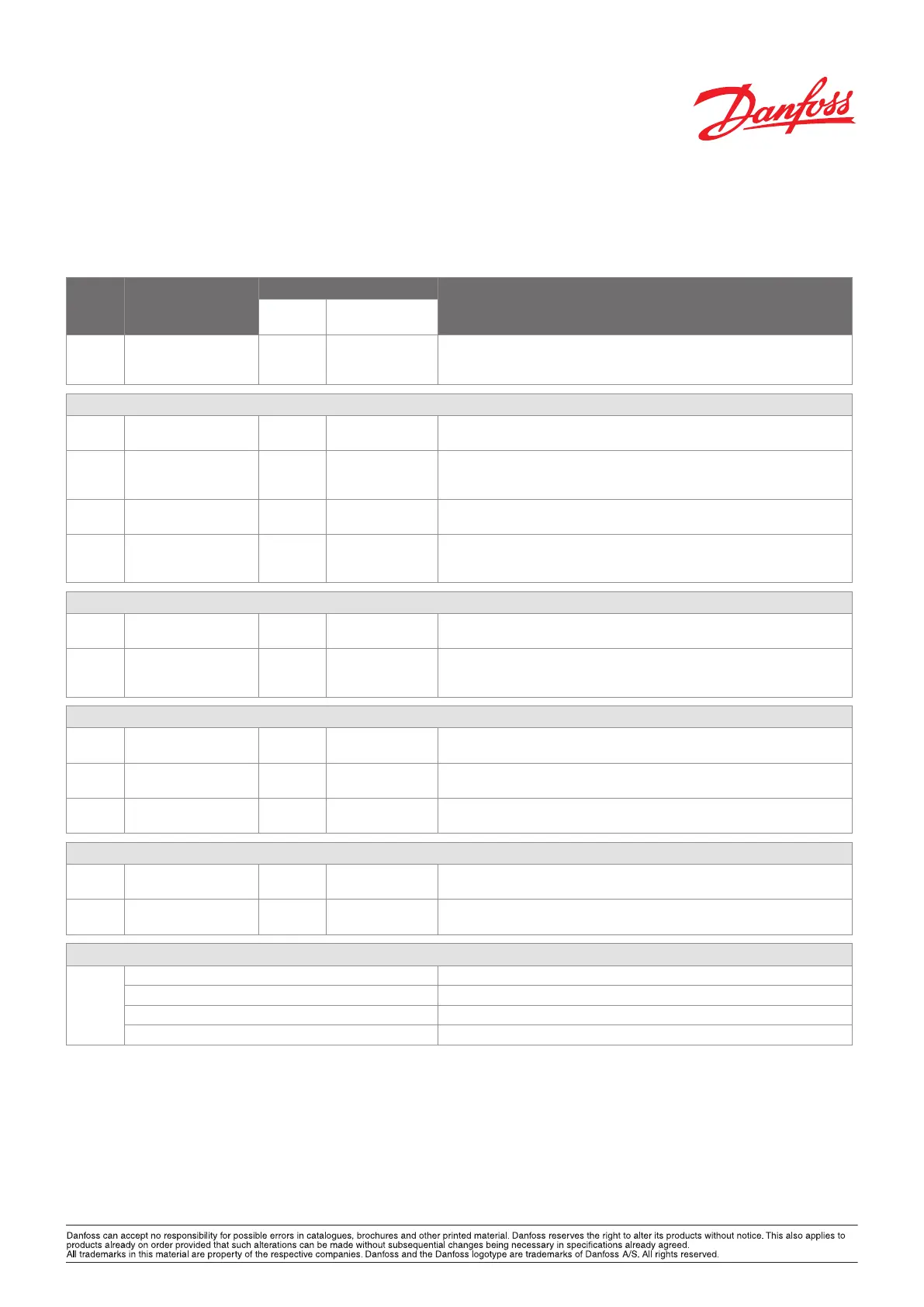

Programming for No-Flow detection

is simplified with a number of para-

meters that are pre-programmed into

the drive. Prior to programming this

feature, commission the drive by

using the parameters in the Quick

Menu Q2 Quick Set-Up. Then perform

the following steps for programming

No-Flow detection:

Par.# Description

Settings

Comments

Factory

setting

Recommended

setting

22-20 Low Power Auto Set-up Disable Enable Close the outlet valve for the pump before starting Auto Set-up. Select Enable

and follow the instruction on the LCP. After Auto Set-up is complete, open the

pump outlet valve.

The following parameters are accessed through the Main Menu and will be stored after pressing the [OK] key to save the results after the auto-tuning

22-33 Low Speed

[Hz]

When Low Power Auto Set-up is used, 50% of the drive’s maximum frequency

will be stored here. This can be manually edited, if desired.

22-34 Low Speed Power [kW] When Low Power Auto Set-up is used, the output power measured under

no-flow conditions at 50% speed will be stored here. This can be manually

edited, if desired.

22-37 High Speed

[Hz]

When Low Power Auto Set-up is used, 85% of the drive’s maximum frequency

will be stored here. This can be manually edited, if desired.

22-3 High Speed Power [kW] When Low Power Auto Set-up is used, the output power measured under

no-flow conditions at 85% speed will be stored here. This can be manually

edited, if desired.

These parameters are used after Auto Set-up and the No-Flow feature is operating

22 - 30 No-Flow Power When the drive is running, this parameter will show the power level that will

be interpreted as producing no flow at the current motor speed.

22 - 31 Power Correction

Factor

100% 110% This parameter is used to raise or lower the no-flow power curve to the

percentage entered here. Values above 100% help ensure the drive reliably

detects no-flow.

The following parameters determine the action that the drive will take if a no flow condition is detected

22-21 Low Power

Detection

Disable Enable To activate no-flow based on power

22-23 No-Flow Function Off Sleep Mode/

Warning/Alarm

Select action

22-24 No-Flow Delay 10 sec. Set the time delay before the drive will perform the No-Flow Function.

Generally set longer than the decel ramp time.

The following parameters give and indication to a BMS if a no flow condition is detected

5-40 Function Relay [190] No-Flow

Program one of the relays to selection [190], No-Flow. The selected relay will

be activated when No-Flow occurs.

Digital Output [190] No-Flow

A digital output can be used to indicate a no flow condition. Use the

parameter that sets the function of the desired digital output.

The following are used if No-Flow is reported via serial communications

Protocol Warning Word

BACnet BV:77 No Flow

LonWorks nvoWarningword Bit 37

Modbus RTU TU Register 16930 Bit 6 = 1

Programming No-Flow detection

Loading...

Loading...