GENERAL SAFETY RULES

WARNING: Unskilled personnel should never be allowed to assemble,

repair or adjust the equipment, and all necessary precautions must be

taken to prevent accidents before starting work: power supply must

be disconnected (including backup batteries if present). Any use of

this product that is not intended by this instruction booklet and/or any

unauthorised modification to the product or its components relieves

DASPI of any liability arising from consequent damage or injury to

property, people or animals. This product is not suitable for installation

in explosive atmospheres. Keep this handbook carefully, attaching

it to the technical installation leaflet and storing it place where it is

available anyone who may need it and make sure said personnel are

aware of this.

TYPE OF PRODUCT

The SIGILE electronic control unit has been designed to control a

SKY C 24 Vdc model motor for spring overhead or sectional doors.

It is provided with deceleration, electronic clutch (adjustable for both

opening and closing), incorporated receiver, coupling for extractable

receiver and soft start function to ensure longer wear for the mechanical

parts. The control unit has a programmable input for the safety devices,

2 buttons with “person present” operation (for calibrating the limit

switches), a fixed working time of 60 seconds and courtesy light timed

at 90 seconds. DASPI will assume no liability for any unintended or

improper use of the SIGILE control unit.

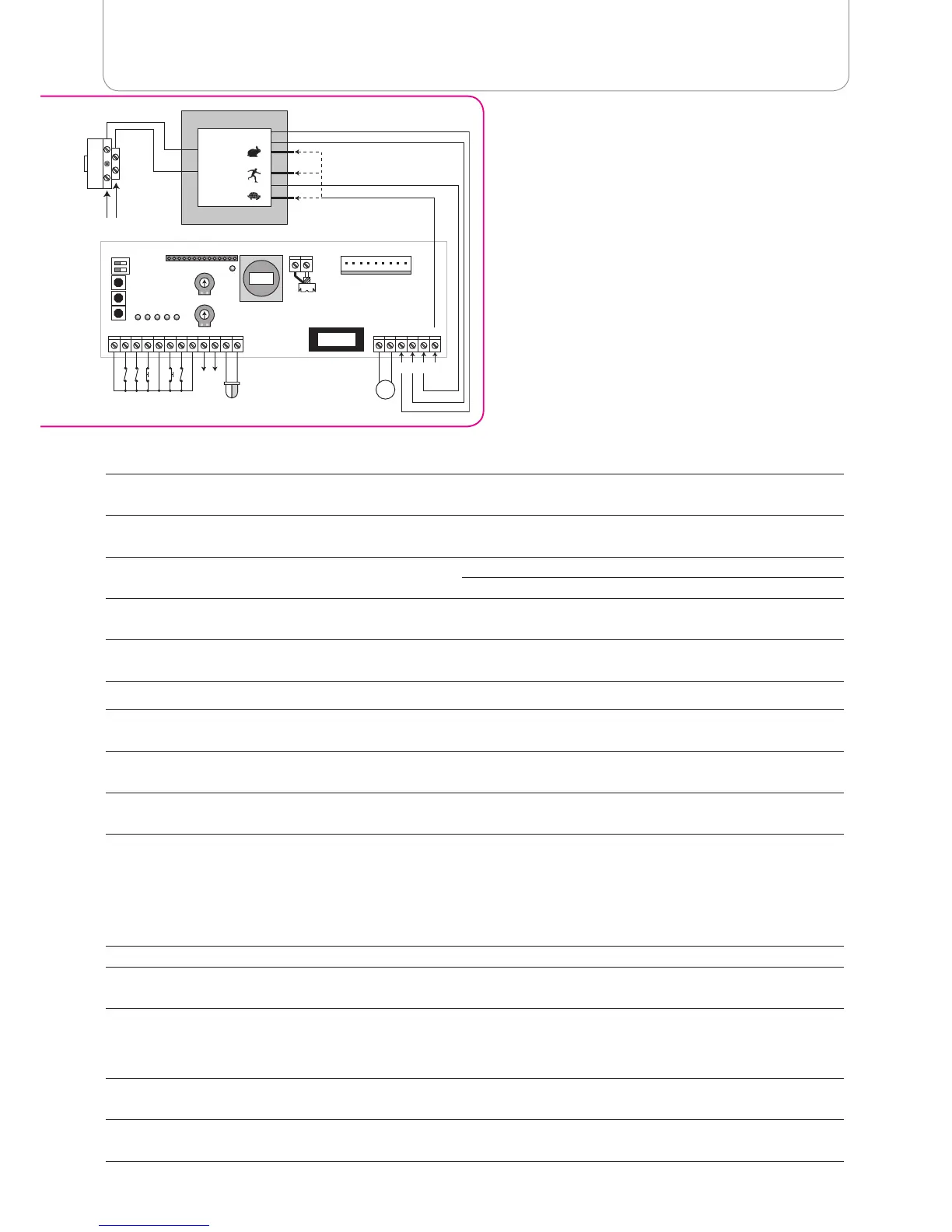

DESCRIPTION OF THE MAIN COMPONENTS

F1

8A fuse to protect 24 V accessories (motor, warning

lamp, courtesy light and 24V output)

P.CLOSE

Button for ‘person present’ closing (calibrating the

closing limit switch) during programming used to select

type of safety device (sensitive edge or photocell).

F2

2A Fuse for protecting 220V transformer primary

P.OPEN

Button for ‘person present’ opening (calibrating the

opening limit switch) during programming used to

adjust automatic closing time.

SW1

For selecting shared operation

/ pre-flashing

CLOSE

Adjustment of motor force during closing

OPEN

Adjustment of motor force during opening

RX

Connector for extractable receiver

J1 Integrated radio module

SET

Button for entering programming

PL1 Courtesy light (24Vdc max 10W)

LED’s indicating status of board input (can be checked after powering the control panel)

F.CH

Indicates status of closing limit switch, N.C. contact,

normally on

START

Indicates status of start control input, N.O. contact,

normally off

F.AP

Indicates status of opening limit switch, N.C. contact,

normally on

SAFE

Input for safety devices (see instructions for selecting

the type of device)

STOP

Indicates status emergency stop input, N.C. contact,

normally on

DL1

Displays programming status (radio learning,

automatic re-closing and type of safety device)

If the above does not tally, check the connections and make sure the various connected devices are working properly.

PROGRAMMING AND ADJUSTMENTS TO THE BOARD

The control unit should always be programmed with the closing limit switch occupied (the door is closed) or after powering the control unit and

before the START control.

PROGRAMMING SW1:

OFF ON

SW1/1

Shared operation disabled

Shared operation enabled (during opening and during automatic closing

time, the control unit does not accept start commands)

SW1/2

Pre-flashing disabled

Pre-flashing enabled (the lamp starts to flash 3 seconds before the

motor starts)

ADJUSTING THE TRIMMER:

CLOSE

Adjusts motor torque during closing, after crossing the preset threshold the motor stops and reverses for 2 seconds

(clockwise to increase, anti-clockwise to decrease) it is OFF during deceleration.

OPEN

Adjusts motor torque during opening, after crossing the preset threshold the motor stops and reverses for 2 seconds

(clockwise to increase, anti-clockwise to decrease) it is OFF during deceleration.

S I G I L E / E R X E L E C t R o n I C Co n t R o L u n I t

Loading...

Loading...