Access the wiring harness at the most suitable place(s) and identify

the wires you are going to connect to using suitable safe test

equipment. Analogue meters and bulb based test lights are low

resistance and can easily damage delicate electronic units tted to

some machines. It is advisable to use high resistance test equipment

(e.g. Digital multi-meters, LED based test lights {logic probes}, LCD

testers). If you have doubts regarding the suitability of your test

equipment, please refer to the manufacturer’s workshop manual.

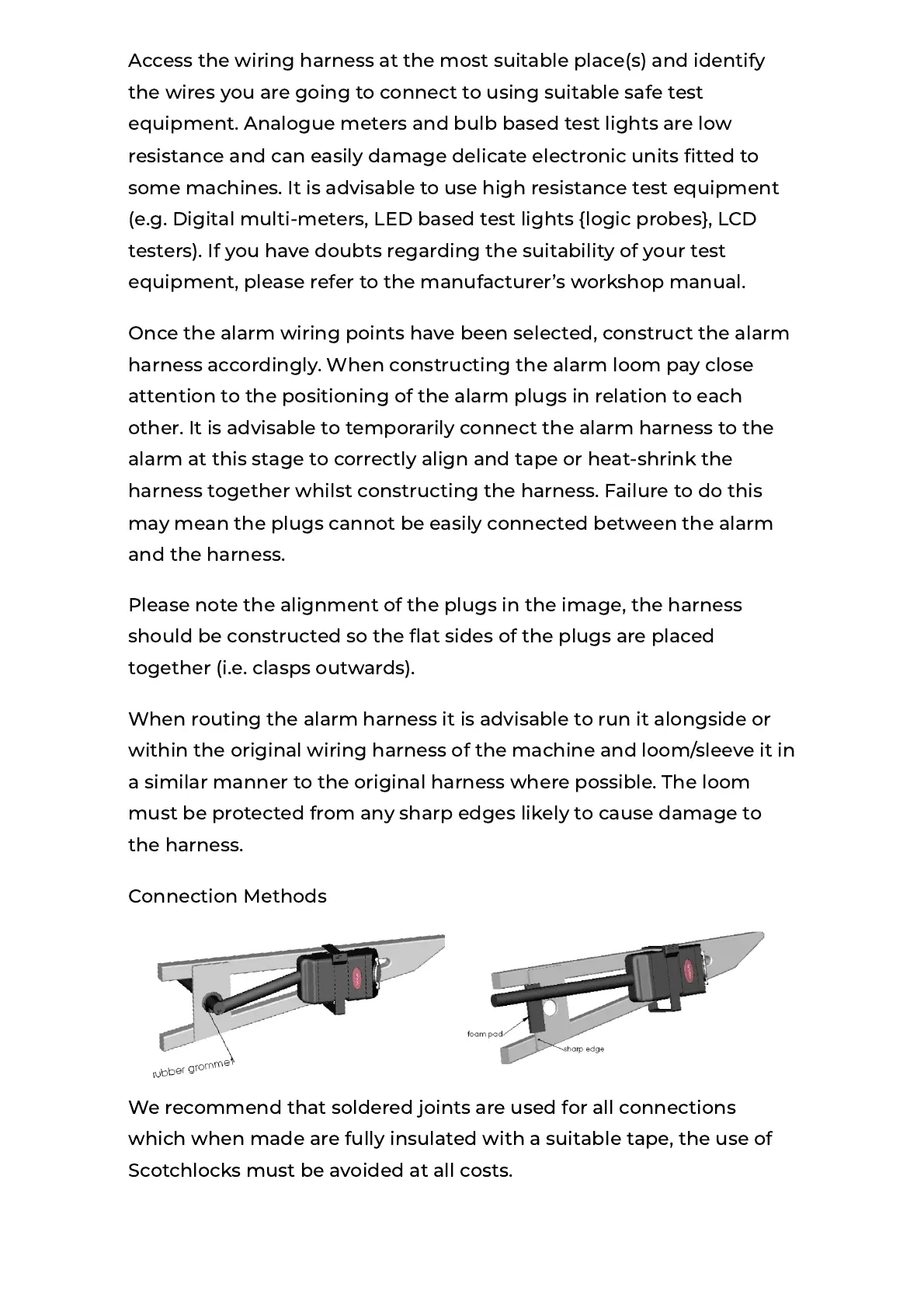

Once the alarm wiring points have been selected, construct the alarm

harness accordingly. When constructing the alarm loom pay close

attention to the positioning of the alarm plugs in relation to each

other. It is advisable to temporarily connect the alarm harness to the

alarm at this stage to correctly align and tape or heat-shrink the

harness together whilst constructing the harness. Failure to do this

may mean the plugs cannot be easily connected between the alarm

and the harness.

Please note the alignment of the plugs in the image, the harness

should be constructed so the at sides of the plugs are placed

together (i.e. clasps outwards).

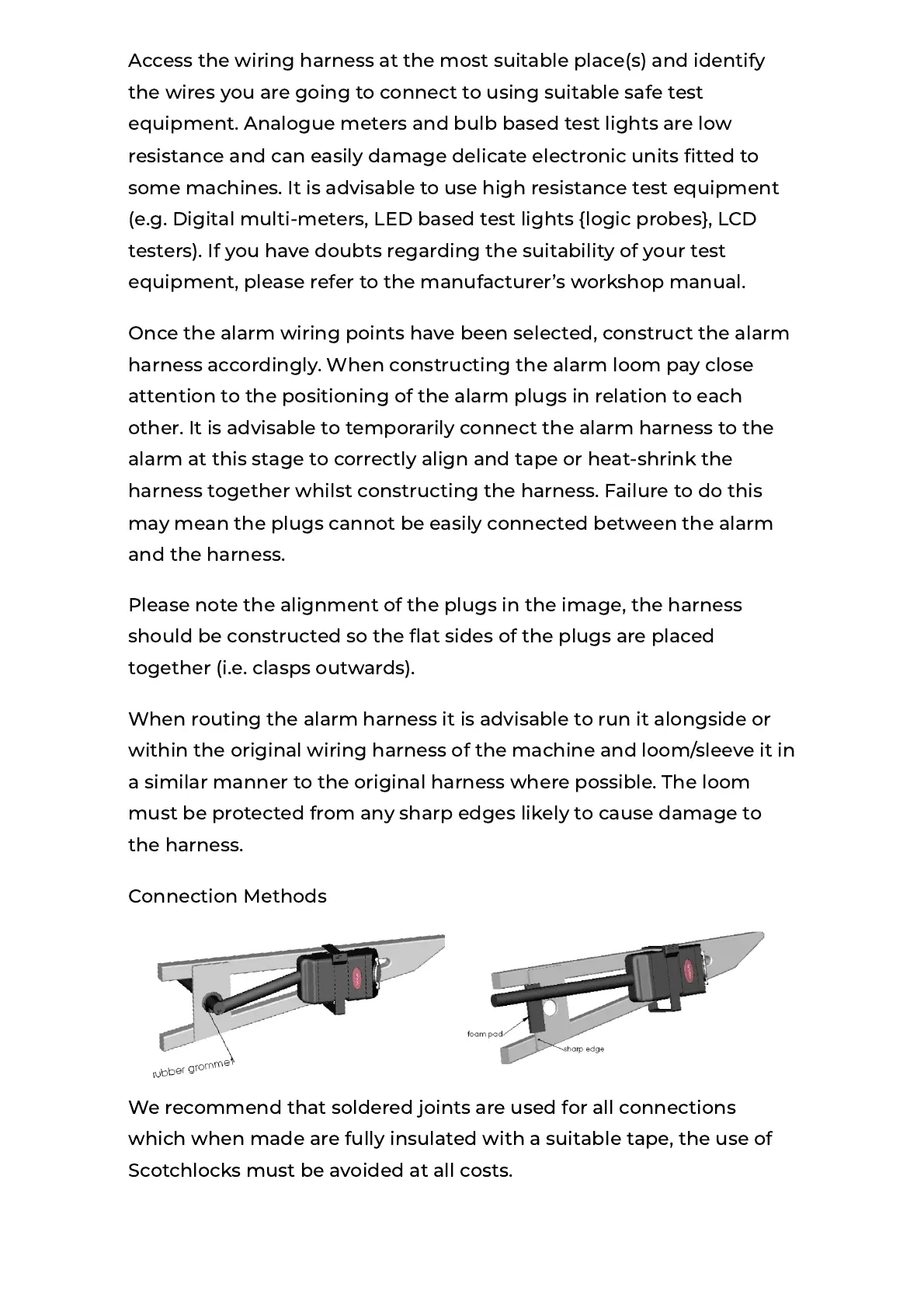

When routing the alarm harness it is advisable to run it alongside or

within the original wiring harness of the machine and loom/sleeve it in

a similar manner to the original harness where possible. The loom

must be protected from any sharp edges likely to cause damage to

the harness.

Connection Methods

We recommend that soldered joints are used for all connections

which when made are fully insulated with a suitable tape, the use of

Scotchlocks must be avoided at all costs.

Loading...

Loading...