11Page

CRIMPING WITH DOUBLE ANGLE DIES

CRIMPING WITH DOUBLE ANGLE DIES

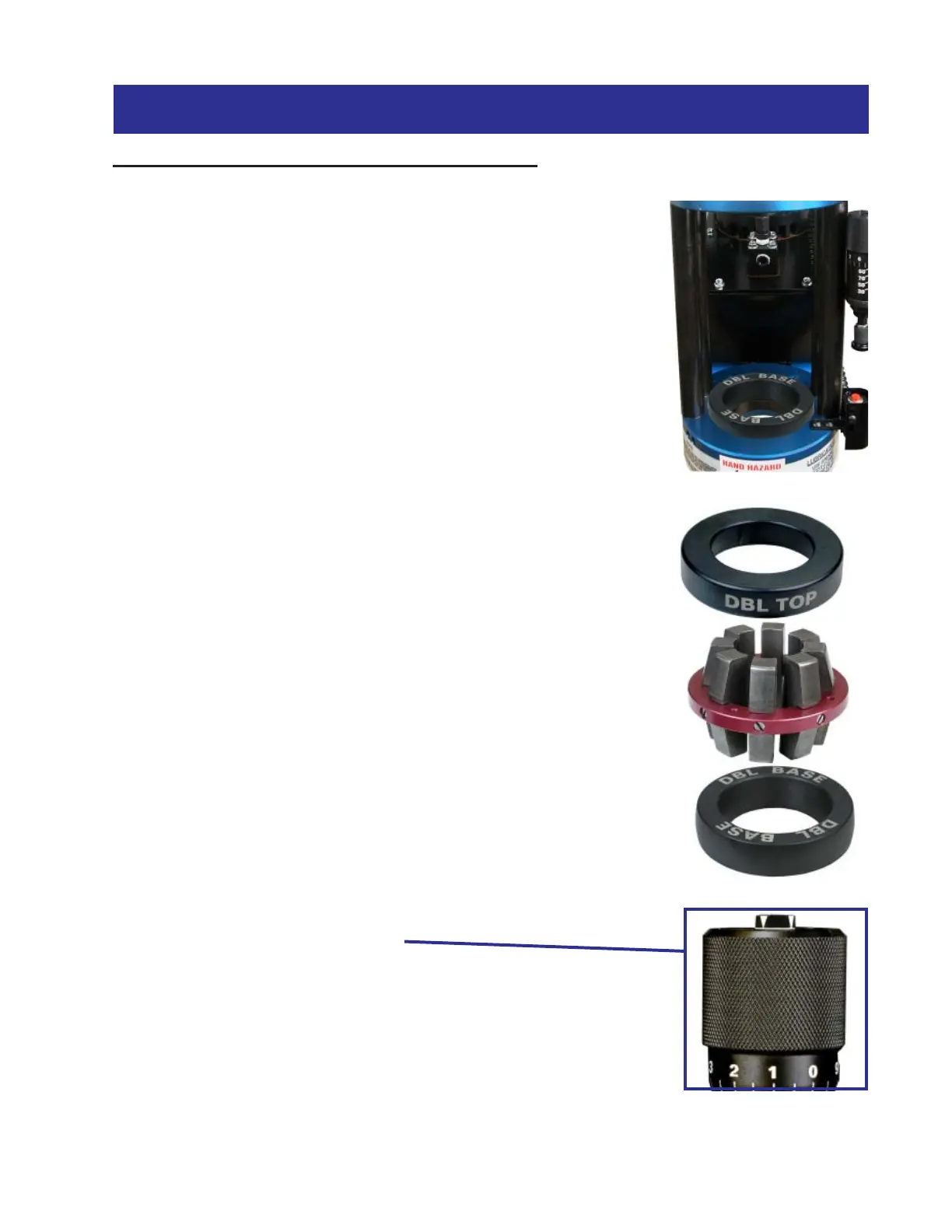

Double Angle dies double the radial crimping force of the die set

allowing heavier fittings to be crimped. Due to the doubling of the

radial crimp force, they are effective for a smaller range of diameters

than a standard die set. Also, the fitting must be approximately centered

axially along the crimping face to avoid taper in the final crimp.

Remove the standard flat Pressure Plate and replace it with

the DBL BASE bottom compression ring.

Note: The angles are not the same on standard and double angle dies

and the standard compression rings are not interchangeable with

double angle compression rings.

Lubricate the contact surfaces of both the upper and lower

compression rings and the outer surfaces of the double angle dies with

the die lubricant furnished with the crimper.

Seat the appropriate size double angle die in the conical recess

of the DBL BASE lower compression ring and align the fitting as

specified by the hose manufacturer.

Place the DBL TOP compression ring on top of the die set and

manually compress the die set until it contacts the fitting.

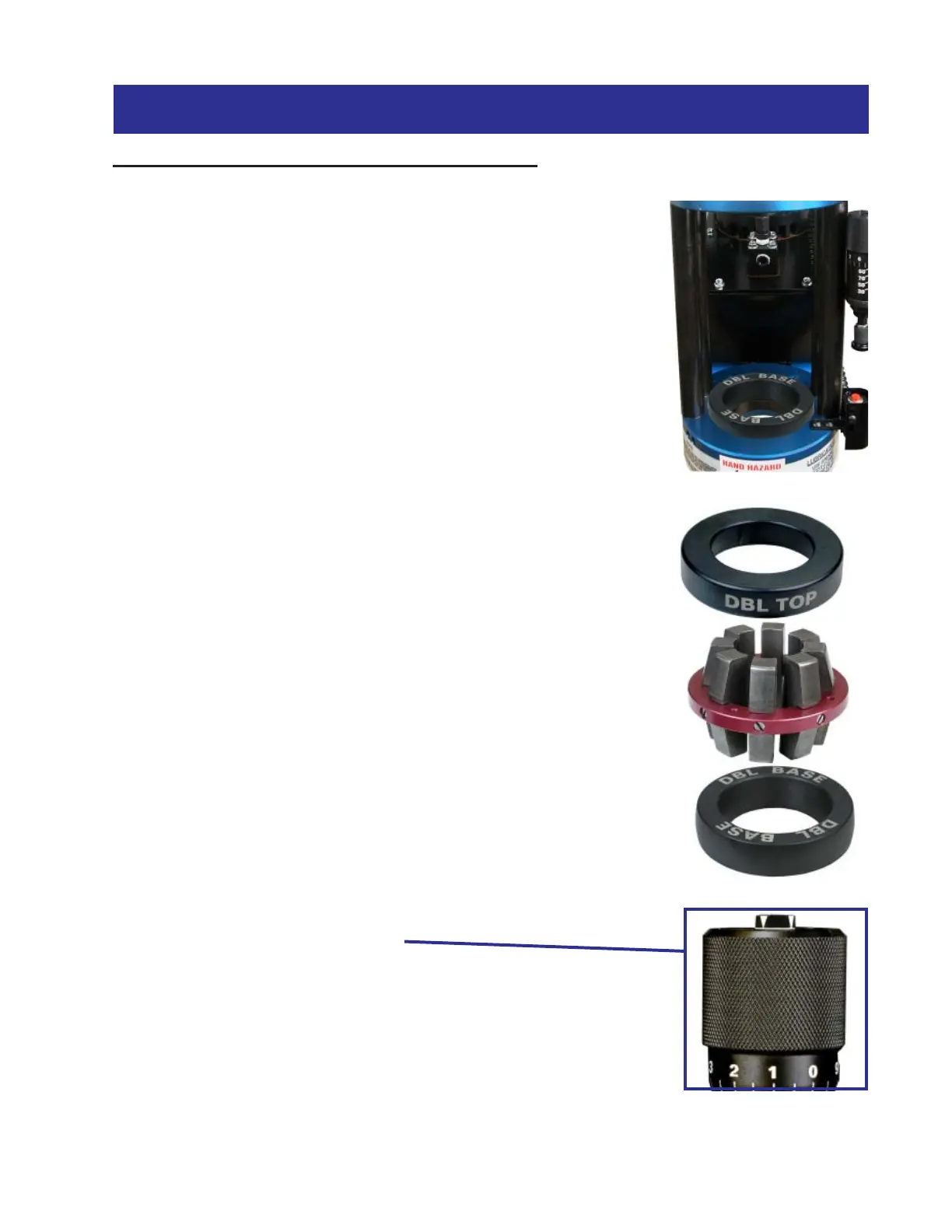

Slide the Pusher onto the cylinder stud and set the Micro-Crimp

Adjuster at the appropriate setting.

Press and hold the Start/Stop switch until the crimper shuts off.

For the D100S-DC, bring the Pusher down until the Micro-Site ring

just appears on the micrometer.

When the crimp cycle is complete, check the fitting diameter

to make certain that it is within the hose manufacturer’s specifications.

Loading...

Loading...