- 11 - 100.6702.6

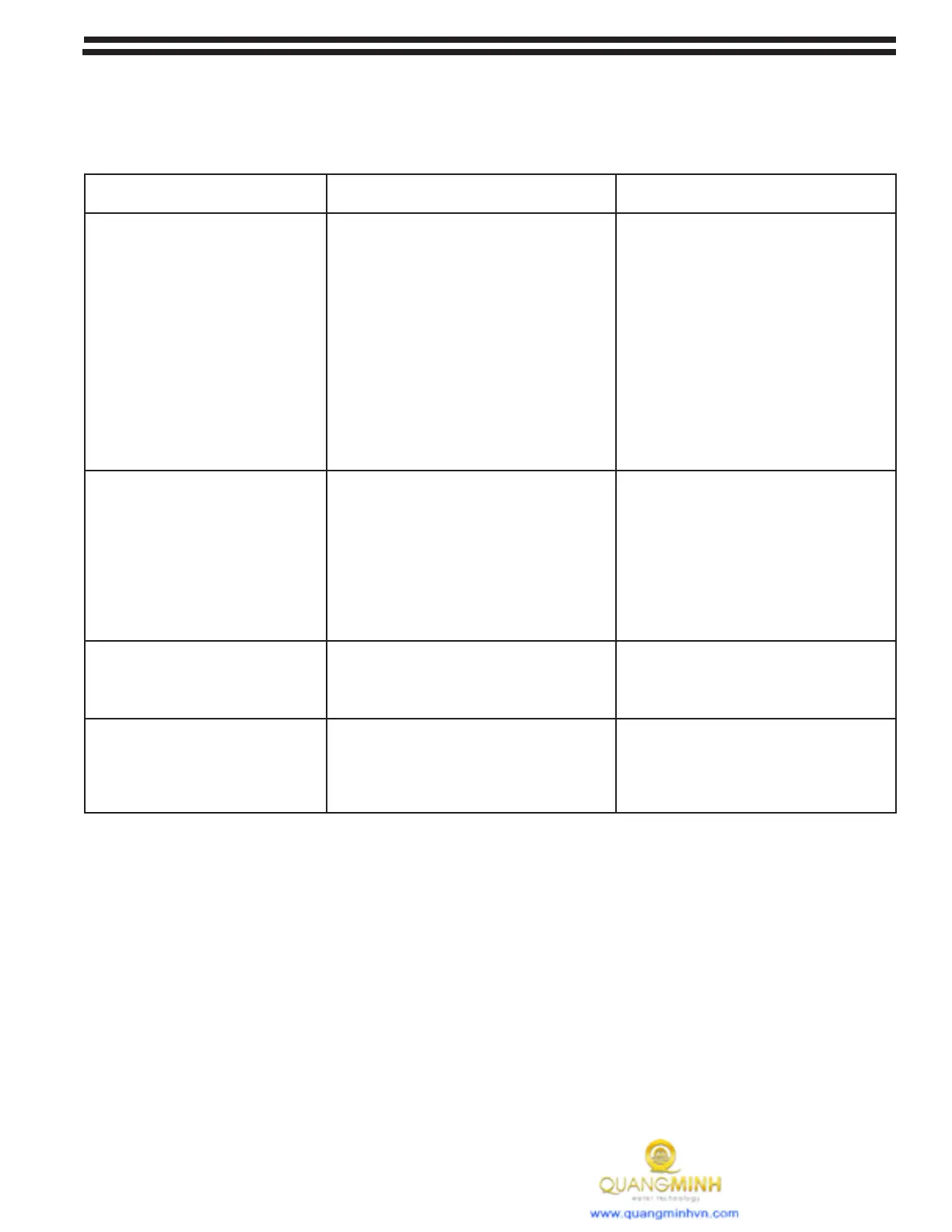

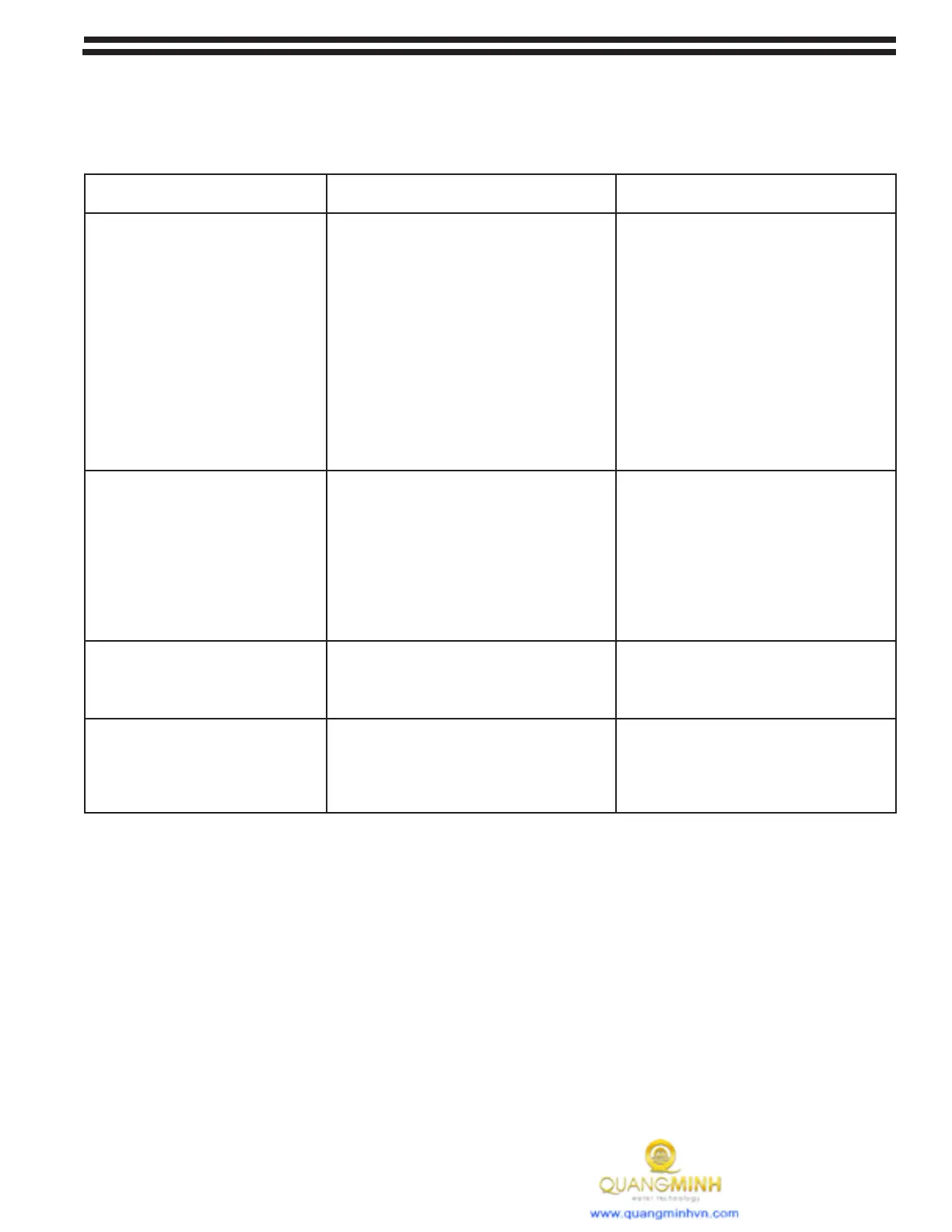

5 TROUBLESHOOTING CHART

Since the operating performance of the meter assembly can be effected by the vacuum regulator and

ejector, also refer to the Troubleshooting Chart in bulletin 100.6701 and 122.6060.

TROUBLE

PROBABLE CAUSE CORRECTIVE ACTION

1. The required gas feed rate

is not achieved at start-up.

a. Insufficient ejector vacuum due to

insufficient water supply pressure

for existing back pressure

conditions.

b. Leakage at vacuum line

connections, vacuum regulator

and/or inlet to ejector.

c. Vacuum line(s) crimped.

d. Length of vacuum line(s) exceeds

maximum allowable transport

distance.

a. Refer to Trouble 2.

b. Inspect each connection and

remake as necessary.

c. Replace vacuum tubing and

arrange line(s) to eliminate

d. Refer to Bulletin 121.3003.

2. Flowmeter ball bounces and/

or maximum gas feed rate

cannot be achieved during

normal operation.

a. Vacuum regulator inlet filter screen

dirty.

b. Rate valve dirty.

c. Flowmeter dirty.

d. Ejector water supply pressure

fluctuating causing insufficient

ejector vacuum. (Ball bouncing

only)

a. Replace gas inlet filter.

b. Clean the rate valve. See Service

section.

c. Clean the flowmeter. See Service

section.

d. Check water supply pressure.

Correct as necessary

3. Flooded metering tube. a. Dirt on the ejector check valve seat,

or worn seat

a. Clean or replace ejector check

valve seat. Refer to Ejector

instruction manual 122.6006,

122.6010, 122.6015, or 122.6060.

4. Vacuum leaks a. Rate valve o-rings worn.

b. Tubing connector loose.

c. Cracks in tubing

a. Replace o-ring.

b. Tighten tubing connector.

c. Replace tubing.

Loading...

Loading...