Delem

V0802, 4.6

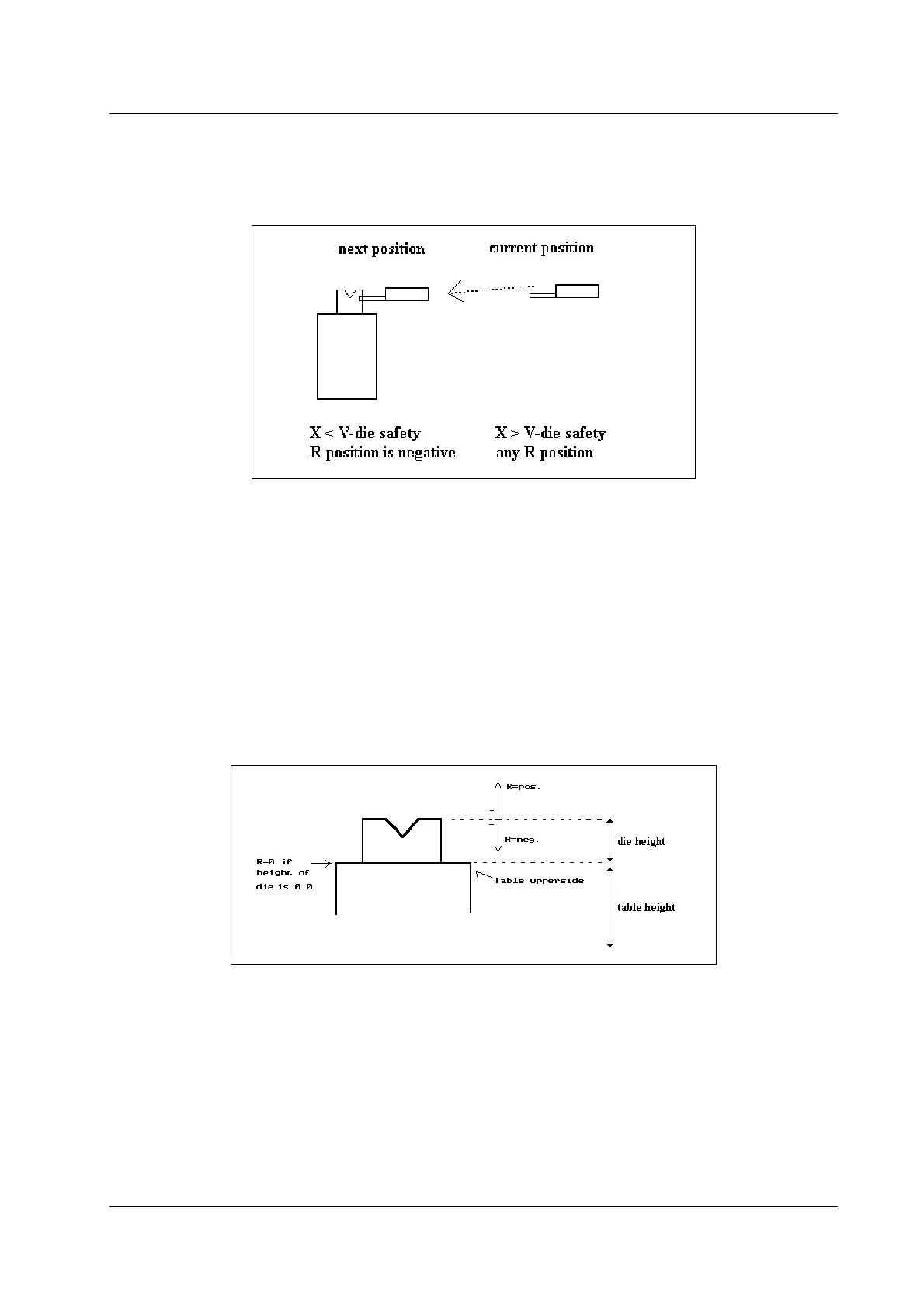

• When the next R-position is negative and within the V-die safety this will always give

collision. The control will give a warning and the "start" button will not be accepted.

Figure 4.3.c

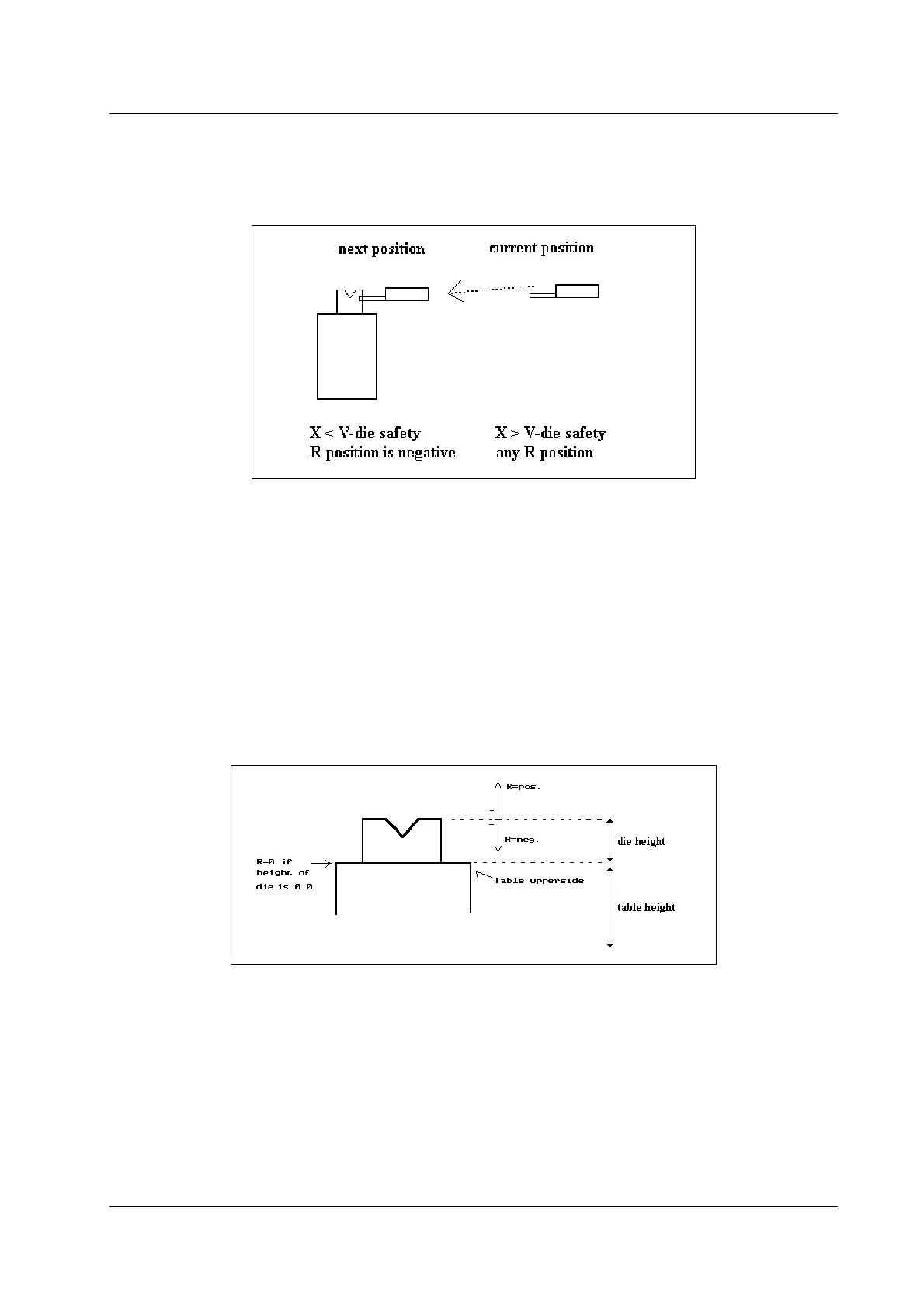

Automatic R-axis adjustment

The zero position of the R-axis always corresponds with the position (height) of the upper side

of the die. When the height of the die changes - you have selected a die with another height - the

zero position of the R-axis is automatically adjusted to the height of the new programmed die.

In the machine parameters menu of the R-axis it is also necessary to program the R-axis

reference value (parameter 5, only in case of encoder position measurement). This parameter is

necessary to be able to adjust the R=0 position to the top of the die. The reference value you

have to program is the distance between the R-axis position at the reference pulse (of the

encoder) and the top of the die.

Figure 4.3.d

Besides the zero position adjustment you also have to program in the machine parameters the

maximum and minimum value of the R-axis. These values are related to the absolute R-axis

values. These R-axis values have to be determined without tools. The maximum value of the R-

axis is the mechanical stroke length above the table and the minimum value of the R-axis is the

mechanical stroke length below the table. So the Rmax. and the Rmin. parameter are related to

the top of the table.

The value of the R-axis on the control screen always relates to the top of the die!

Loading...

Loading...