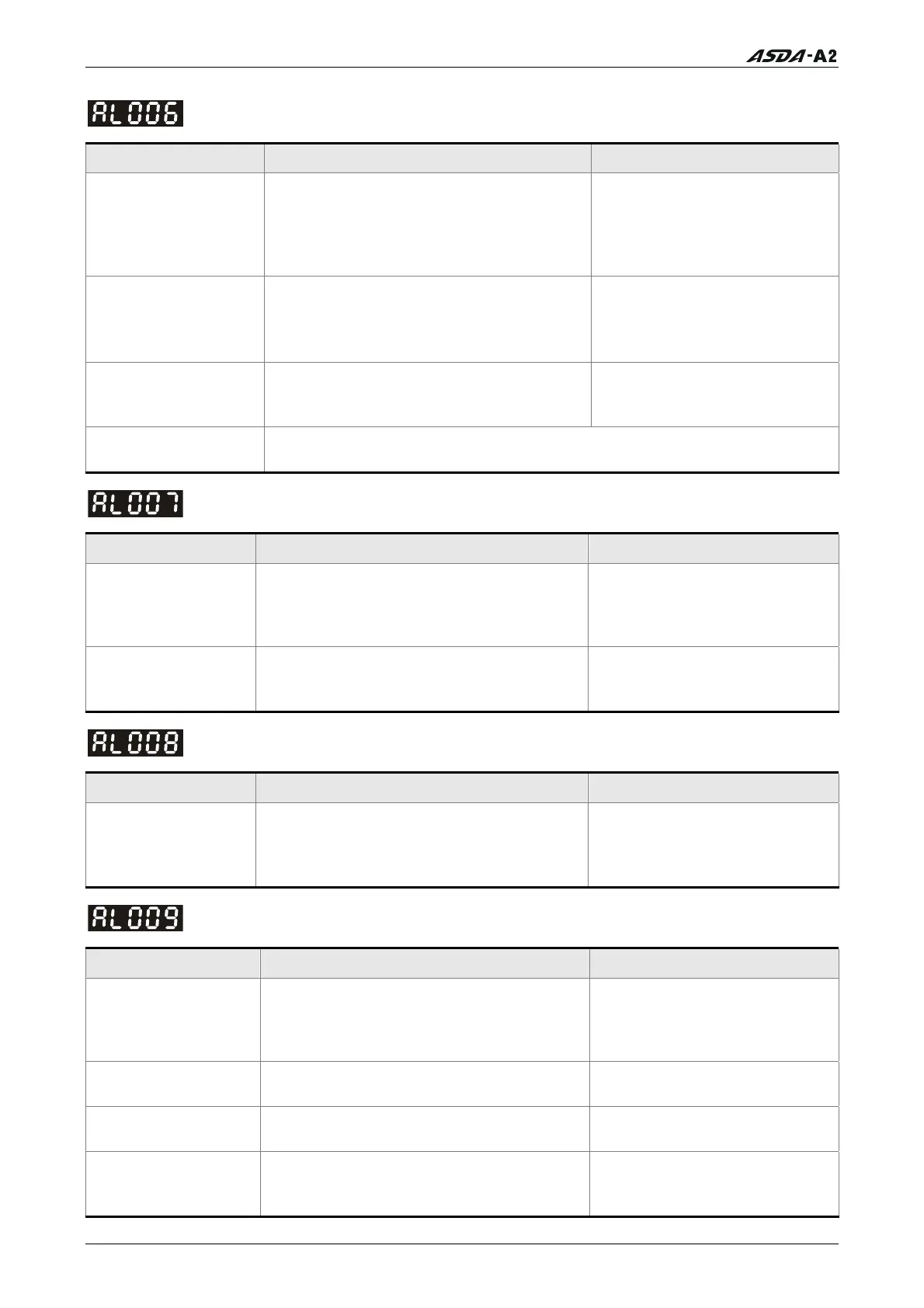

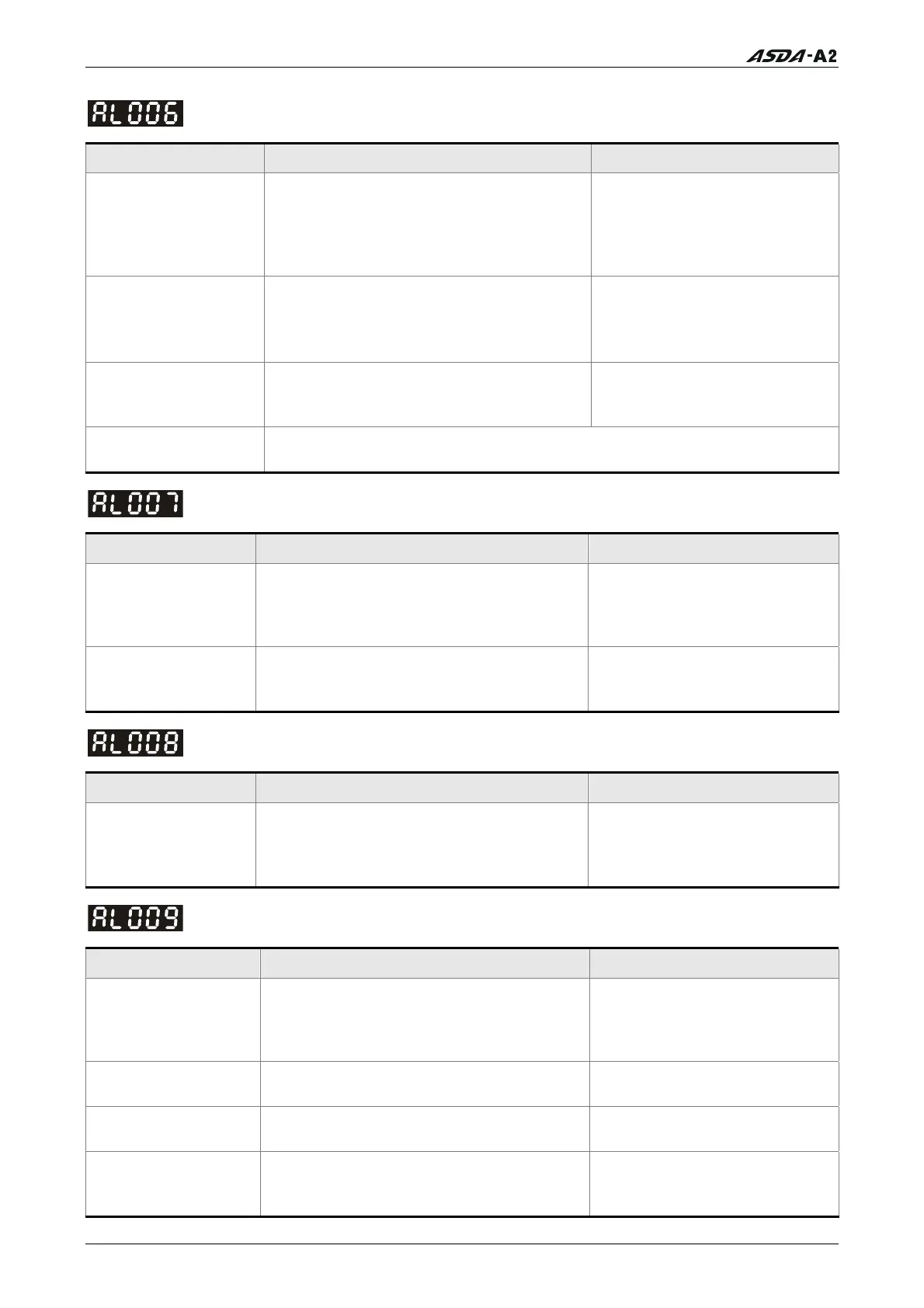

Chapter 10 Troubleshooting

: Overload

Potential Cause Checking Method Corrective Actions

The drive has

exceeded its rated

load during

continuous

operation.

Check if the drive is overloaded. The

users can set parameter P0-02 (Drive

Fault Code) to 11 and monitor if the

value of the average torque [%] exceeds

100% always.

Increase motor capacity or

reduce load.

Control system

parameter setting is

incorrect.

1. Check if there is mechanical vibration

2. Accel/Decel time setting is too fast.

1. Adjust gain value of control

circuit.

2. Decrease Accel/Decel time

setting.

The wiring of drive

and encoder is in

error.

Check the wiring of U, V, W and

encoder.

Ensure all wiring is correct.

The encoder of the

motor is damaged.

Please contact your distributor for assistance or contact with Delta.

: Overspeed

Potential Cause Checking Method Corrective Actions

Speed input

command is not

stable (too much

fluctuation).

Use signal detector to detect if input

signal is abnormal.

Ensure that input command

frequency is stable (not

fluctuate too much) and

activate filter function.

Over-speed

parameter setting is

defective.

Check if over-speed parameter setting

value is too low.

Correctly set over-speed

parameter setting (P2-34).

: Abnormal pulse control command

Potential Cause Checking Method Corrective Actions

Pulse command

frequency is higher

than rated input

frequency.

Use pulse frequency detector to measure

input frequency.

Correctly set the input pulse

frequency.

: Excessive deviation

Potential Cause Checking Method Corrective Actions

Maximum deviation

parameter setting is

too small.

Check the maximum deviation

parameter setting and observe the

position error value when the motor is

running.

Increases the parameter

setting value of P2-35.

Gain value is too

small.

Check for proper gain value. Correctly adjust gain value.

Torque limit is too

low.

Check torque limit value.

Correctly adjust torque limit

value.

There is an overload. Check for overload condition.

Reduce external applied load

or re-estimate the motor

capacity.

Revision January 2011 10-9

Call 1(800)985-6929 for Sales

Call 1(800)985-6929 for Sales

Loading...

Loading...