Chapter 5 CPU and Module Devices

5-13

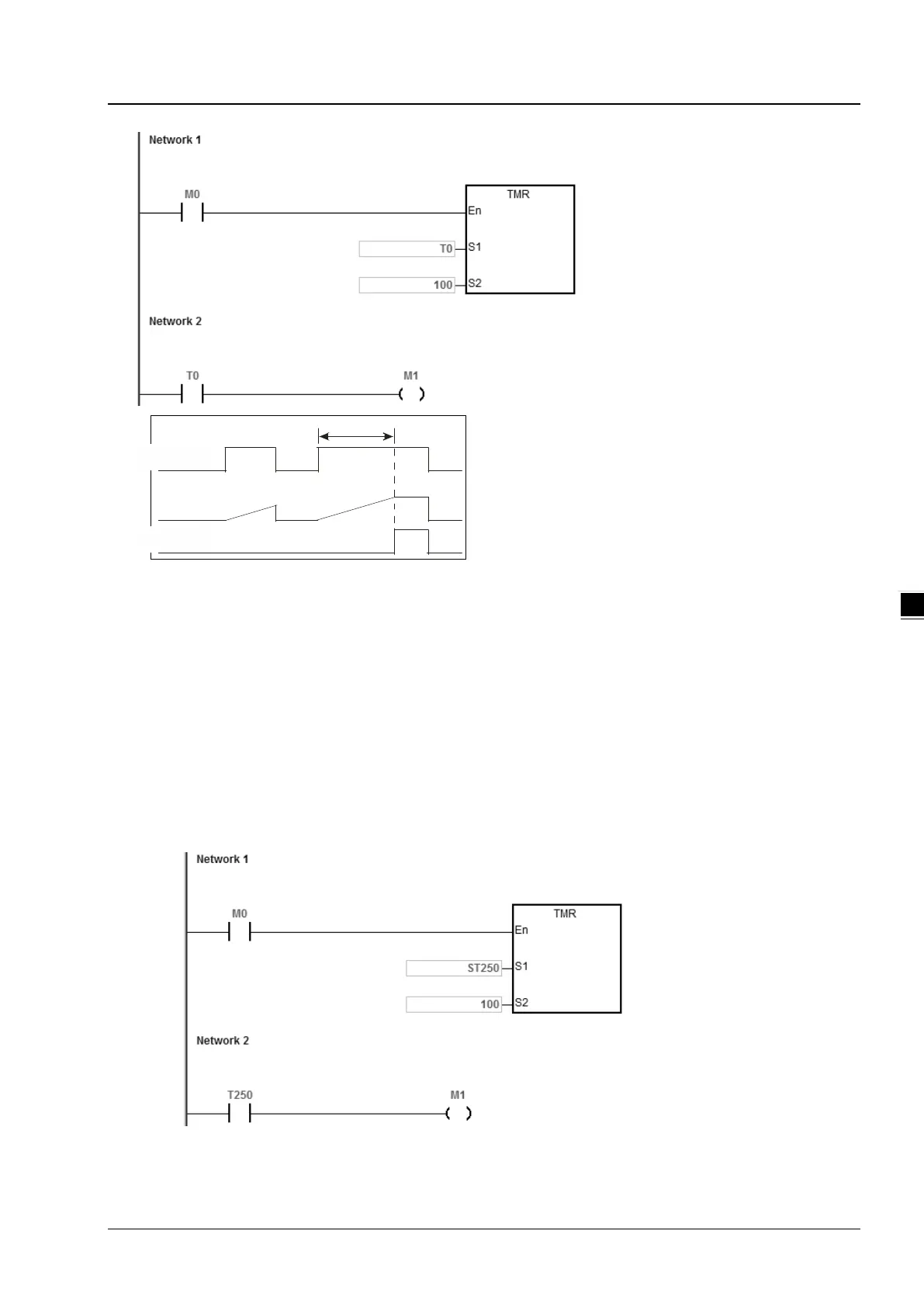

X0. 0

T0(PV)

Y0. 0

SV: K100

10se c

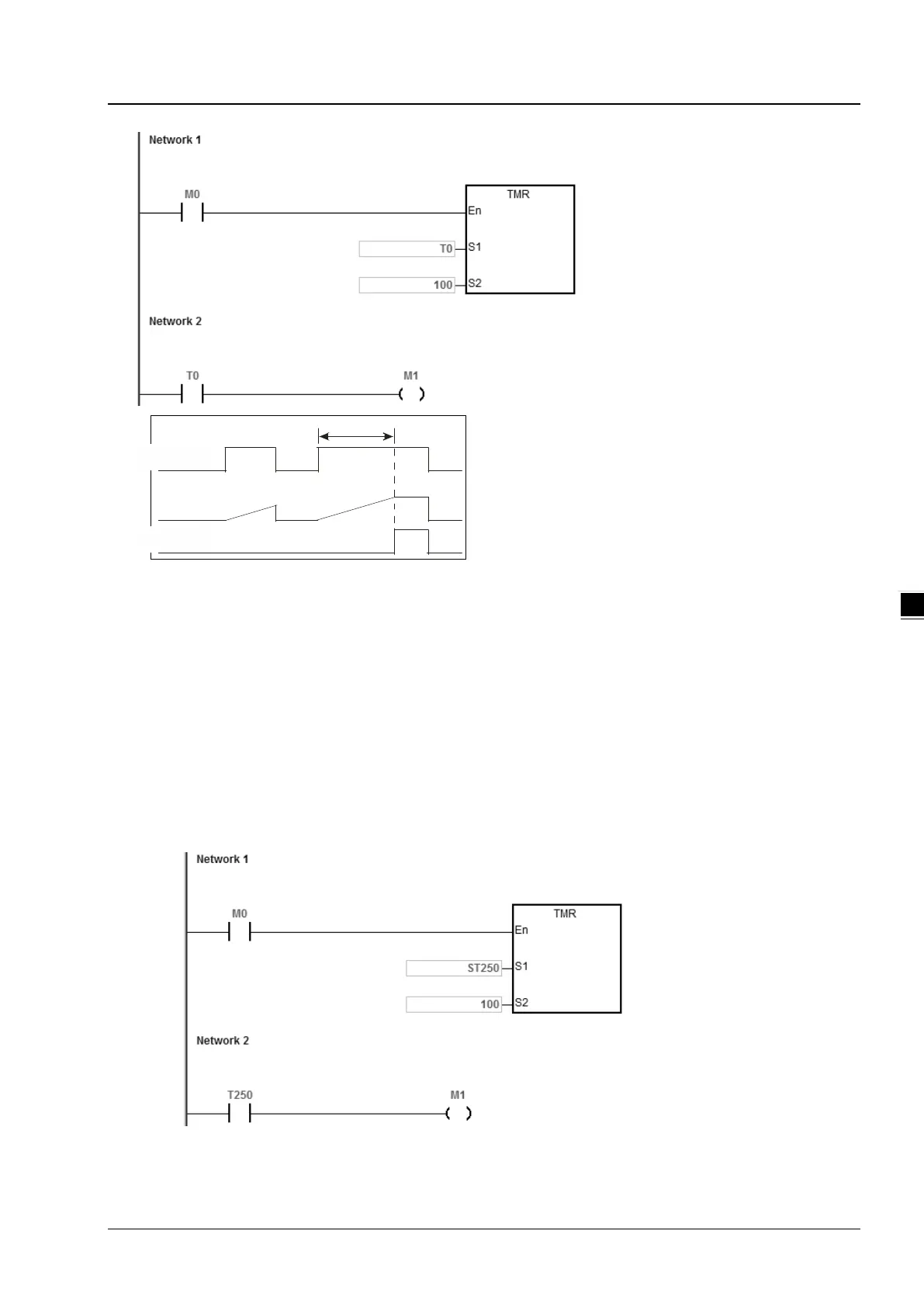

B. Accumulative timers

When the TMR instruction is executed, the accumulative timer begins to count. When the value of the timer matches

the timer setting value, the output coil is ON. As long as you add the letter S in front of the letter T, the timer becomes

an accumulative timer. When the conditional contact is OFF, the value of the accumulative timer is not reset. When

the conditional contact is ON, the accumulative timer counts from the current value.

• When M0=ON and the timer T250 takes 100 ms as the timing unit, the output coil T250 is ON when the value

of the timer = timer setting value 100.

• When M0=OFF or the power is off, the accumulative timer ST250 stops counting, and the value of the timer

stays the same. When M0=ON, the value of the timer is the accumulating value. When the accumulated value

= timer setting value 100, the output coil T250 is ON.

Loading...

Loading...