Chapter 12 Description of Parameter SettingsCP2000

12.1-08-2

Analog Input Selection (AVI1)

Default: 1

Analog Input Selection (ACI)

Default: 0

Analog Input Selection (AVI2)

Default: 0

Settings 4: PID target value

Common applications for PID control

1. Flow control: Use a flow sensor to feedback the flow data and perform accurate flow

control.

2. Pressure control: Use a pressure sensor to feedback the pressure data and perform

precise pressure control.

3. Air volume control: Use an air volume sensor to feedback the air volume data to achieve

excellent air volume regulation.

4. Temperature control: Use a thermocouple or thermistor to feedback temperature data for

comfortable temperature control.

5. Speed control: Use a speed sensor or encoder to feedback motor shaft speed or input

another machine speed as a target value for closed loop speed control of the master-slave

operation. Pr.10-00 sets the PID set point source (target value).

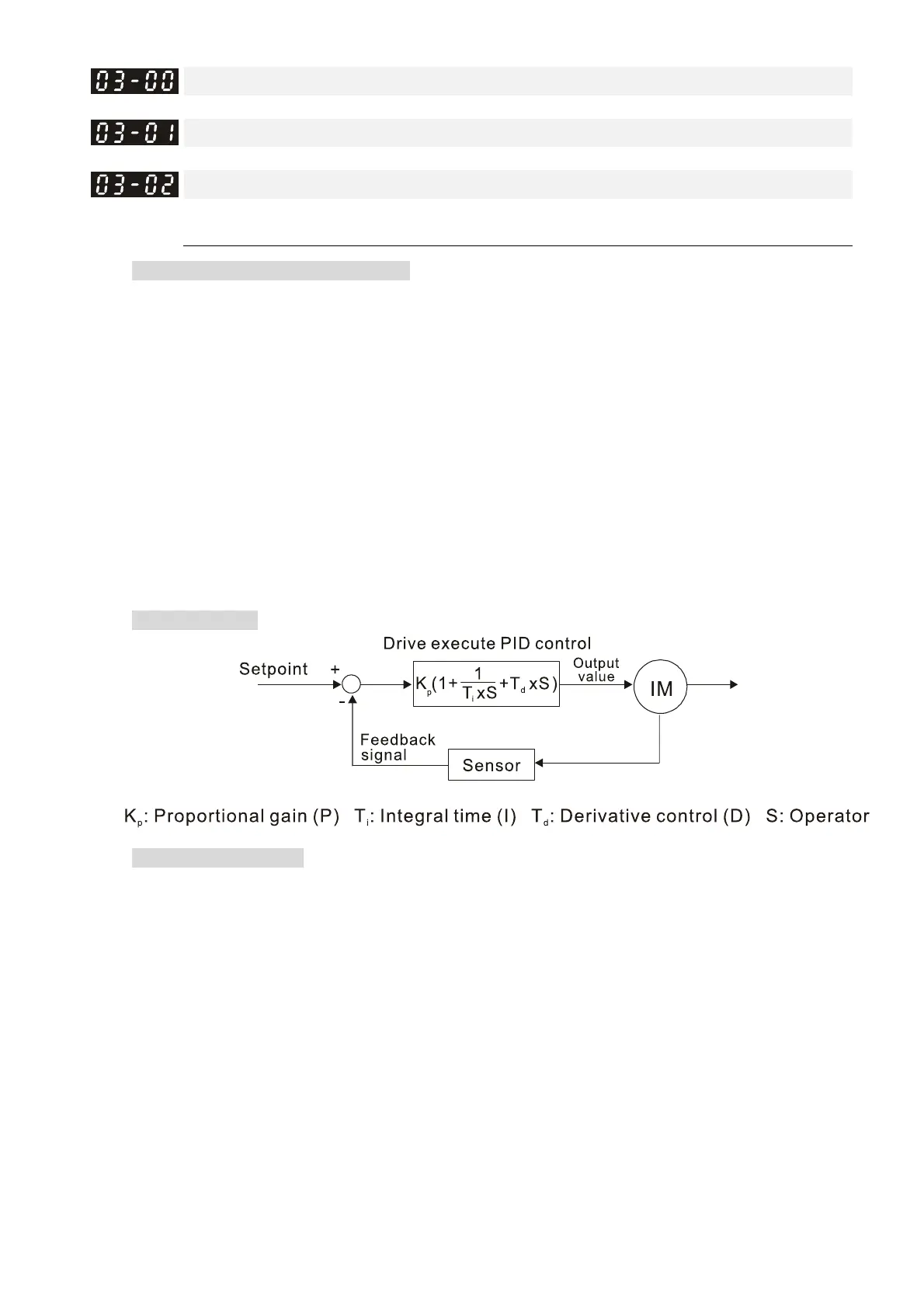

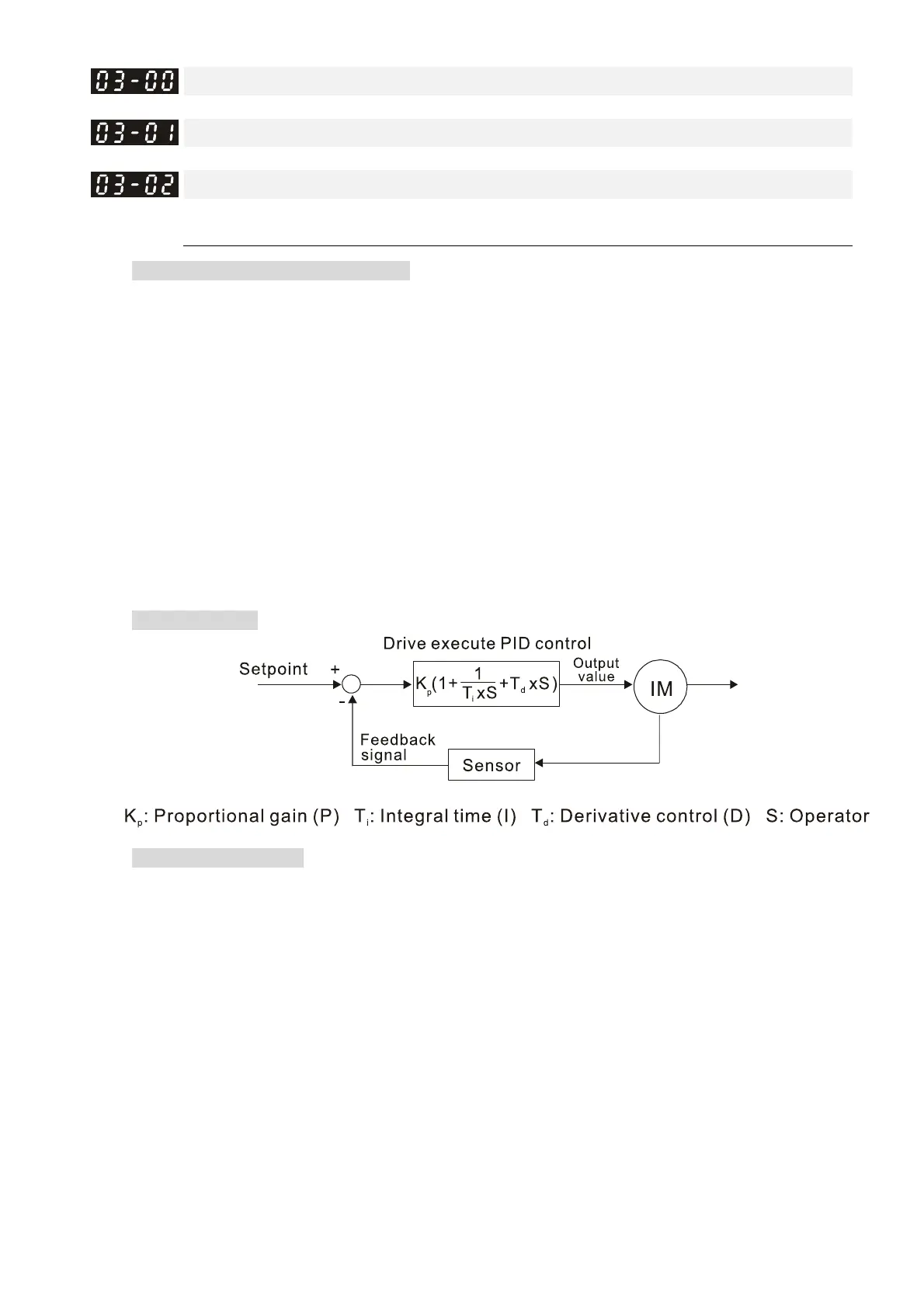

PID control loop:

Concept of PID control

Proportional gain (P):

The output is proportional to input. With only proportional gain control, there is always a

steady-state error.

Adjustment: Turn off the Ti and Td, or remain Ti and Td in constant value, then adjust the

proportional gain (P).

Increase: Faster status feedback, but excessive adjustment will increase the overshoot.

Decrease: Smaller overshoot, but excessive adjustment will slow down the transient

response.

Integral time(I):

The controller output is proportional to the integral of the controller input. To eliminate the

steady-state error, add an “integral part” to the controller. The integral time controls the

relation between integral part and the error. The integral part increases over time even if

Loading...

Loading...