1. Common applications for PID control:

Flow control: Use a flow sensor to feedback the flow data and perform accurate flow

control.

Pressure control: Use a pressure sensor to feedback the pressure data and perform

precise pressure control.

Air volume control: Use an air volume sensor to feedback the air volume data to achieve

excellent air volume regulation.

Temperature control: Use a thermocouple or thermistor to feedback temperature data for

comfortable temperature control.

Speed control: Use a speed sensor to feedback motor shaft speed or input another

machine speed as a target value for synchronous control.

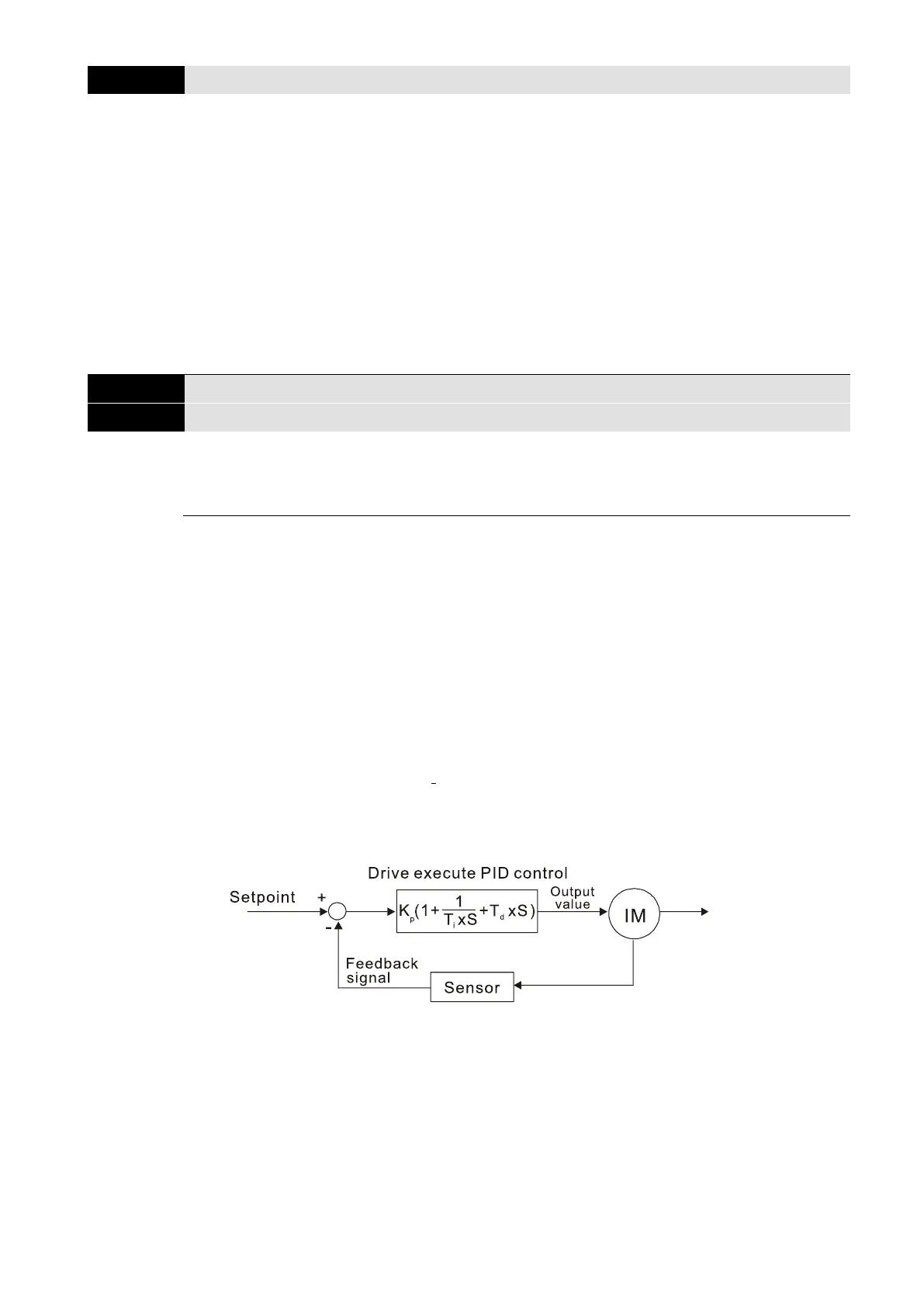

2. PID control loop:

K

P

Proportional Gain (P), Ti Integral Time (I), T

d

Differential Time (D), S Calculation

3. Concept of PID control:

Proportional gain (P):

The output is proportional to input. With only a proportional gain control, there is always a

steady-state error.

Loading...

Loading...