Delta Treatment Systems • 9125 Comar Drive, Walker, LA 70785 • 1-800-219-9183 • www.deltatreatment.com

9

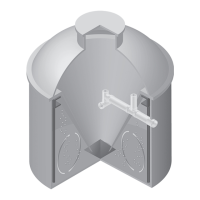

INSTALLATION INSTRUCTIONS INSTALLATION INSTRUCTIONS

ONLY FOR USE BY CERTIFIED,

LICENSED INSTALLERS

1. Ooading and Handling

Care must be taken when ooading; and unpacking

components. Care must be taken not to damage berglass

with forklift or any other ooading device. Check for

any damaged components that may have happened in

transportation and notify factory within 24 hours of delivery.

Prepare an excavation, having a diameter approximately

one foot larger than the tank and a depth that will allow

approximately 3 inches of the inspection port to extend

above normal ground level. Backll with a 6-inch layer of

sand or gravel if otherwise unable to provide a smooth,

level, compact base. We recommend that the hole be roped

o in some fashion to prevent injury to passersby.

Component List (Example DF50)

1 – DF50 ATU

1 – DF50 Compressor Package

HP80 – air pump

GV12MIA – ½” galvanized male insert adapter

PV34X12FB – ¾” x ½” PVC slip x female bushing

54175K14 – 7/32” x 5/8” worm drive clamp

1 – CP20 alarm panel

8x6 polycarbonate enclosure

(5) wire terminals

(1) fuse holder w/5 amp fuse

(1) red pilot light (on outer door)

(1) two way silence switch (on outer door)

(1) alarm buzzer

(1) alarm pressure switch

(1) vent pipe assembly

2. Inlet and Outlet

Using lifting lugs provided, place the plant in the excavation

so that the inlet and outlet line up with the sewer piping.

The inlet line should slope down toward the plant and the

outlet line should slope down away from the plant. The plant

should be level within 1/2 inch, edge to edge.

Position inlet and outlet lines and make connections as

necessary, depending upon the construction materials. The

inlet line should be inserted and glued into the inlet elbow

and the discharge line should be inserted and glued into the

outlet coupling.

Note: Open inspection port and make sure discharge tee

assembly is level and centered in clarier prior to attaching

discharge piping. Fill the tank with water until water ows

from the discharge before backlling. Backll around

the treatment plant up to the bottom of the discharge

connections.

3. Air Pump

Do not install the air pump(s) in a low-lying area where water

may accumulate. The air pump should be installed near the

control panel and within 100 ft. of the tank. The air pump

can be installed outdoors or in a clean, well-ventilated area,

such as a tool room, garage, etc. If the linear air pump is to

be installed in an additional enclosure, the enclosure must

be approved by Delta Treatment Systems in writing.

4. Control Panel

A. Install the oat switch wire from the control panel to the

treatment plant. Wire can be direct burial type UF 600 volt

or can be installed in Schedule 40 PVC conduit. Use type

THWN, 600 volt if installed in conduit. Wire must be buried

in accordance with NEC table 300-5. If in doubt, bury 24”

deep. Keep sucient distance or depth from airline to avoid

confusion of pipes or damage to wiring during installation

or repair of air piping. Connect to the oat switch normally

open contacts using underground rated compound lled

wire nuts.

To set the high level pressure switch that detects high water

level in the unit, follow the instructions below:

Bring plant to operating water level with compressor turned

on. Using properly sized screwdriver, turn high-level alarm

adjustment screw clockwise until alarm occurs. Then turn

the screw counterclockwise until alarm stops. (See “high

level pressure setting” drawing in this manual.)

B. Connect the pressure air tubing to the 1/8” barb-tting

directly to the 3/4” airline or directly to the compressor.

Refer to illustrations in Appendix B for appropriate air tubing

connections.

C. Install 3/4” Schedule 40 PVC piping between air pump

and treatment unit. A minimum of 12” ground cover is

recommended.

Loading...

Loading...