10

As soon as the pump and driver have reached the normal

operating temperature, the unit should be shut down for

¿ nal coupling alignment. This should be done by following

the instructions found in Section B, Part 4.

After the unit has been running for about one week,

the coupling halves should be given a ¿ nal check for

misalignment caused by pipe strains or temperature

strains. If the alignment is correct, both pump and driver

may be dowelled to the baseplate if desired.

D. MAINTENANCE

1. LUBRICATION

Grease Lubricated Pump

Pump bearings are properly lubricated with grease at the

factory before shipment. Periods of subsequent lubrication

depend on local conditions, loads, speeds, hours of

operation and temperature.

Periodic inspection of bearing lubrication should be made

and additional grease added as needed. At this time the

plug in the bottom of the bearing cover should be removed

and the bearing À ushed with clean grease. A Chevron

SRI-2 or Shell Dolium “R” grease is recommended for

most installations. Do not overgrease as this causes high

bearing temperatures and shortens bearing life. The pump

should be run a short time to eject any excess grease and

the plug then replaced in the bearing cover.

Oil Lubricated Pump

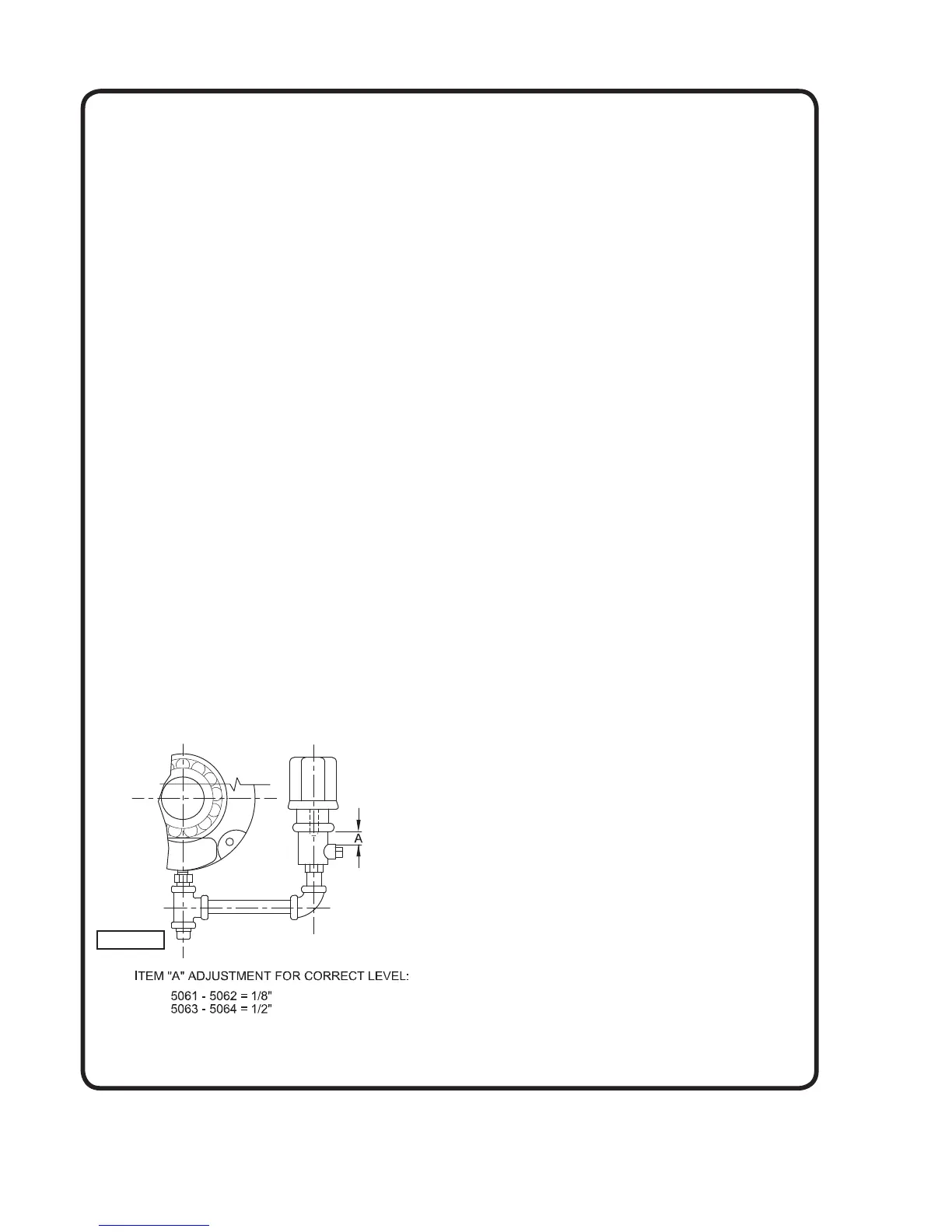

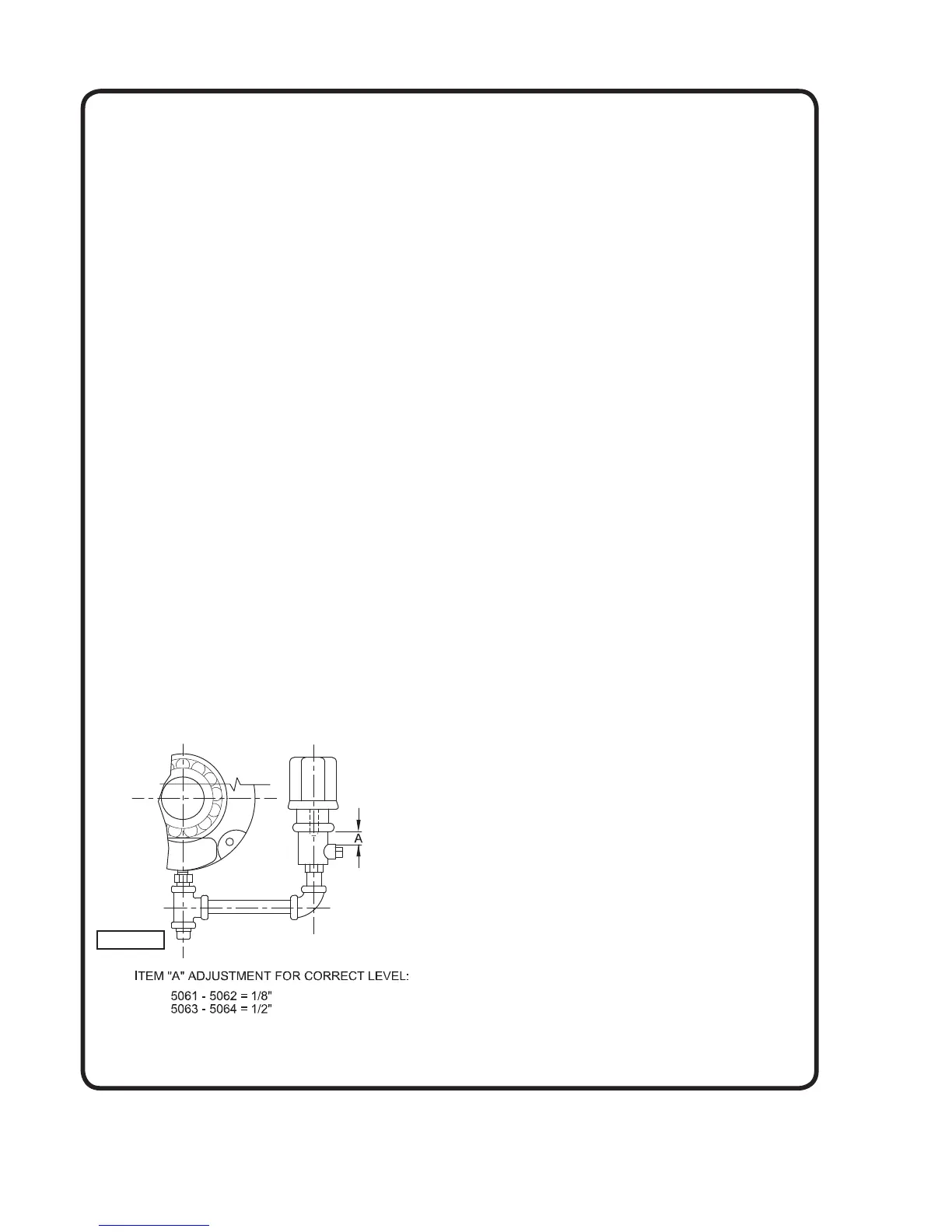

The pump is shipped without oil in the bearing housings.

Fill the reservoir to the proper level from shaft centerline as

follows:

The following lubricants are recommended at the operating

temperature indicated. See Figure 5 for correct oil levels.

0°F - 150°F, - S.A.E. #10 Wt. Non-detergent oil

150°F - 250°F, - S.A.E. #20 Wt. Non-detergent oil

Motor bearings should have periodic attention and

lubricated in accordance with the motor manufacturer’s

recommendations.

2. PACKING BOX

The packing glands should be adjusted occasionally to

insure proper packing lubrication. A slow dripping through

the gland is recommended for good lubrication and long

packing and shaft sleeve life.

When installing new rings of packing, clean packing box

and inspect parts for any damage. If the shaft sleeve is

worn or grooved, it should be replaced. New packing will

not do an adequate sealing job on a worn shaft sleeve.

Insert two new rings of packing in front of lantern ring.

Stagger joints to minimize leakage.

Tamp each ring in place. Replace lantern ring. Add two

rings of packing behind lantern ring. Replace gland and

bolts, rotate shaft and tighten gland securely. Loosen the

gland and add the ¿ nal ring of packing. Be sure lantern

ring is positioned to receive lubrication through ori¿ ce.

Tighten nuts securely to seat packing and rotate shaft.

After rotating several turns, loosen nuts to ¿ nger tight for

starting.

3. WEARING RINGS

Wearing rings are ¿ tted in the casing on all pumps and

are standard on the impeller of all pumps with 8” or larger

discharge. (Optional on smaller units). These wearing rings

provide a close running clearance, to reduce the quantity

of liquid leaking from the high pressure side to the suction

side. These rings depend on the liquid in the pump for

lubrication. They will eventually wear so that the clearance

becomes greater and more liquid passes into the suction.

This rate of wear depends on the character of the liquid

pumped. When worn excessively these rings will cause

the pump to loose ef¿ ciency and should be replaced.

Recommended wear ring clearances are as follows:

Model C.I. or Bz. Stainless Steel

5061 .009/.014 .019/.024

5062 .011/.016 .021/.026

5063 .013/.018 .023/.028

5064 .016/.023 .029/.036

4. DISASSEMBLY

The following procedure is for complete disassembly of the

pump. If complete disassembly is not necessary, use only

those steps which apply.

a. Disconnect coupling from driver before proceeding.

b. Disconnect seal water lines (if used). Remove oiler

piping on oil lube pumps.

c. Remove split gland and clips.

d. Remove bolts and nuts and lift off upper half casing

(1B).

e. Remove gasket (73) and soak in water.

f. Match mark and remove bearing caps (41) and (43).

g. Lift out rotating element.

h. Remove bearing caps.

i. On grease lubricated pumps, open tangs of bearing

lockwasher (69), unscrew and remove bearing lock

nut (22). Remove lockwasher. For oil lubricated

pumps, remove both oil rings (60). Unscrew and

remove both bearing lock nuts (22).

Figure 5

Loading...

Loading...