8

3.9. Delivery

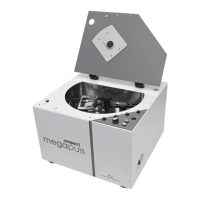

1 High frequency casting machine megapuls compact - 230 V REF 090-620-00

1 Instructions for use with declaration of conformity

1.5 m Fabric reinforced fresh water hose with connection piece

3

/

4

´´, inner diameter 8 mm

1.5 m Water outlet hose inner diameter 8 mm

2 Crucibles

1 Mains cable

4. Description of the induction casting machine megapuls compact

4.1. Function

The megapuls compact is an easy to operate induction casting machine in a compact and space saving

construc-

tion, which can be used to melt all dental alloys (exception: titanium and titanium alloys) and subsequently

cast

into a casting ring. It is equipped with manual operation and gradual heating adjustment and can be

used universally. The machine functions using an energy transmission principle, a transformer, creating the

so-called induction heating method. When the high frequency magnetic field is switched on, a secondary electrical

current flows through the metal by means of induction. This converts into heat and causes the metal to melt.

The eddy current created within the molten metal causes the molten mass to become thoroughly mixed.

The subsequent centrifugal force which casts the molten material into the form also helps with

homogenisation.

The megapuls compact‘s outstanding characteristics are:

• High melting power with low energy consumption

• Homogeneous melting and casting method

• Low material wastage

• Extra work is reduced

• Easy to operate

• Space saving construction

• Friendly service.

4.2. Unit construction

The high frequency generator, which is surrounded by steel sheet housing, is the heart of the machine and

complies with electromagnetic compatibility requirements. The HF generator produces an electromagnetic field

and heats and mixes the molten metal to create a homogeneous molten mass. The induction coil (Fig. 4, Pos. 18)

is cooled by water which prevents it from overheating.

• The melting crucible and casting ring can both be placed into the casting arm (Fig. 4) within the melting and

casting chamber. The casting arm is equipped with weights to maintain a well-balanced and smooth run.

• The heating element, the induction coil (Fig. 4, Pos. 18), is situated in the base of the chamber and can be raised

into position by pressing the „START“ button (Fig. 3, Pos. 12) after having adjusted the casting arm.

• The melting process is started by closing the lid and can be observed through the protective glass integrated

within the lid (Fig. 2, Pos. 4).

• The melting process is completed by pressing the „CASTING“ button (Fig. 3, Pos. 14).

Loading...

Loading...