EN

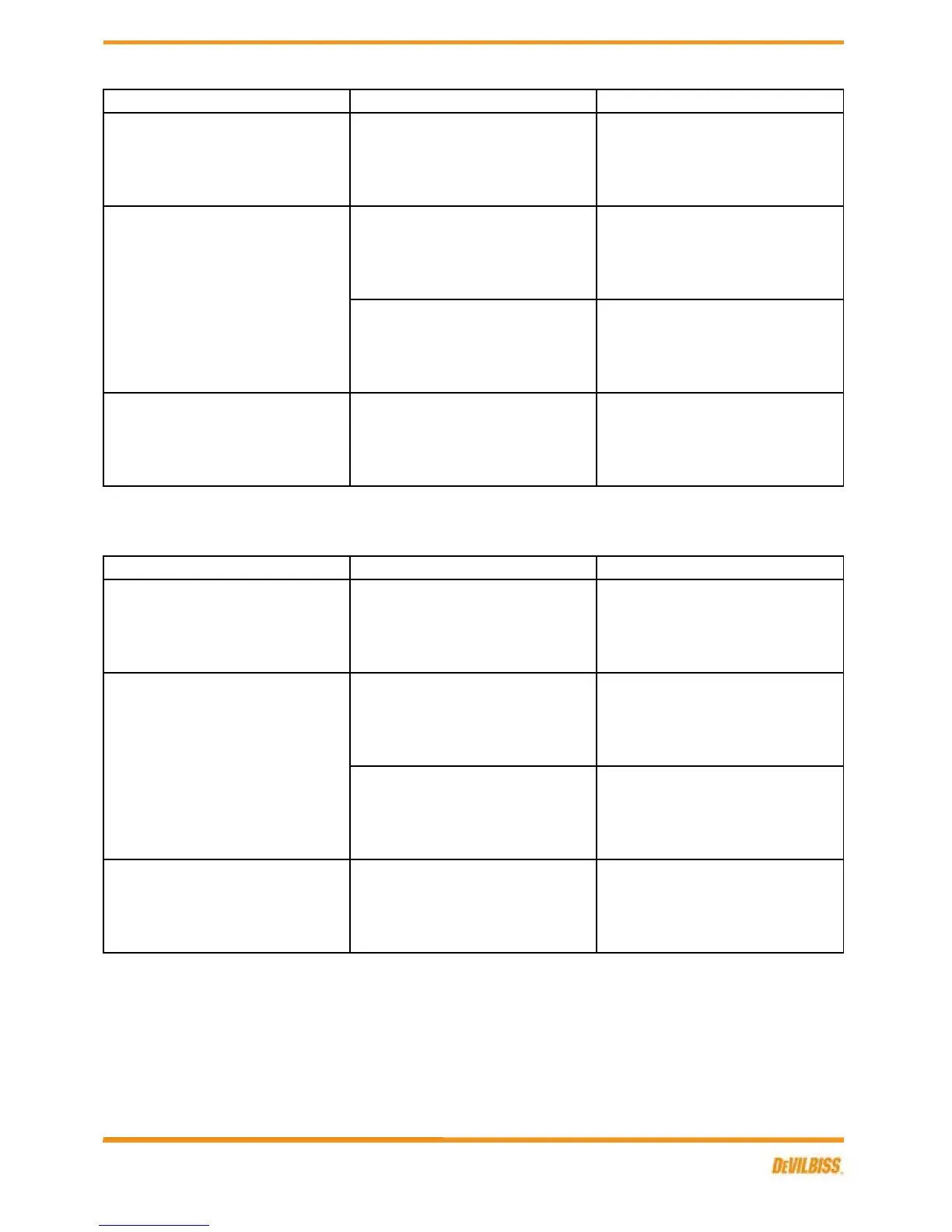

Locking cam is not in the unlock

position.

Turn locking cam lever to unlock

position on manifold.

Locking cam is not in the unlock

position.

Spray gun does not locate onto

manifold.

Turn locking cam lever to unlock

position on manifold.

Spray gun is loose when assembled

onto manifold.

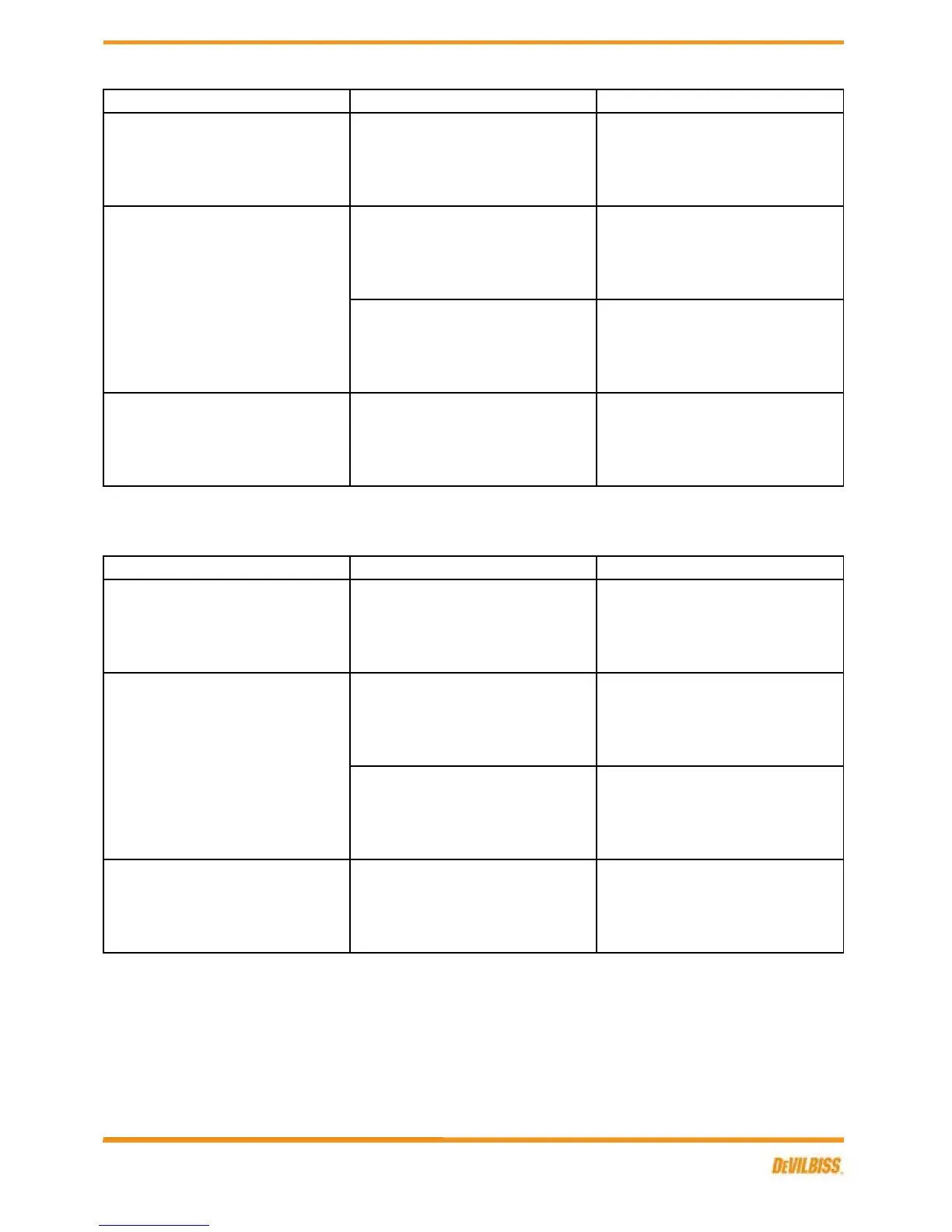

SCREW TYPE MANIFOLD FAULTS

Spray gun does not locate onto

manifold.

Clamping screw has not been

tightened.

Clamping screw has worn.

Spray gun is loose when assembled

onto manifold.

Spray gun cannot be removed from

manifold.

Item 29 - locking pin still in place.

Clamping screw still in place.

Replace using clamping screw kit

SPA-161-K2.

Spray gun cannot be removed from

manifold.

ASSEMBLY FAULTS CAUSE

Remove clamping screw.

Locking cam has worn.

Remove item 29 - locking pin.

CAUSE CORRECTION

LEVER TYPE MANIFOLD FAULTS

Tighten screw.

Turn locking cam lever to lock

position on manifold.

Replace using locking cam kit

SPA-424-K

CORRECTION

Locking cam has not been tightened.

ASSEMBLY FAULTS

SB-E-2-643 R5.0

19/28

Loading...

Loading...