SB-2-194-K Page 3

Fluid Tip Size I.D.

Tip No. In. mm

AV-213-10 0.039 1.0

AV-213-12 0.047 1.2

AV-213-13 0.051 1.3

AV-213-14 0.055 1.4

AV-213-16 0.063 1.6

AV-213-18 0.070 1.8

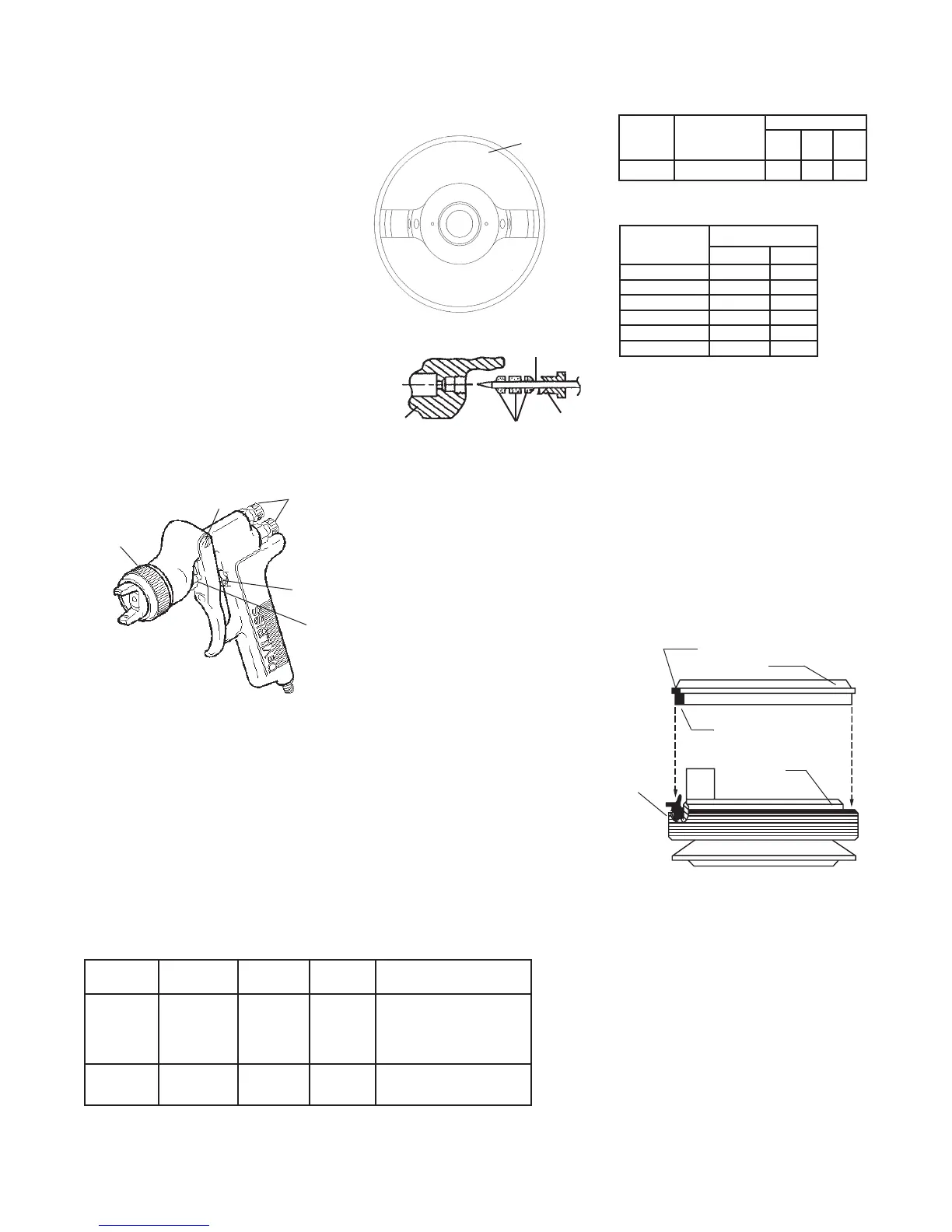

JGA-4035 Packing Replacement Instruc-

tions

1. Remove adjusting knob and needle

spring from gun.

2. Partially withdraw needle from gun

body.

3. Loosen packing nut and remove.

4. Remove old packing.

5. Assemble packing nut to needle

6. Assemble packing in order shown to

needle.

7. Insert needle all the way into gun

body seating in tip.

8. Install needle spring and adjusting

knob.

9. Thread packing nut into gun body.

10. Tighten packing nut in equal

increments - no more than 1/6 turn

at a time.

11. After each adjustment, pull needle

open and observe needle closure.

12. If needle snaps shut, continue

adjusting nut until there is evidence

of needle bind or slow closing.

13. Back off packing nut 1/12 turn to the

point where needle snaps shut.

Packing nut must remain tight

enough to prevent loosening by

hand.

14. Pull needle several times to verify

needle snaps shut and check

packing nut for looseness.

SPRAY GUN LUBRICATION

Daily, apply a drop of SSL-10* spray gun

lube at trigger bearing stud (28) and the

stem of air valve (20) where it enters air valve

assembly. The shank of fluid needle (11)

where it enters packing nut (9) should also

be oiled. Fluid needle packing (8) should be

lubricated periodically. Make sure baffle (6)

and retaining ring (3) threads are clean and

free of foreign matter. Before assembling

retaining ring to baffle, clean the threads

thoroughly, then add two drops of SSL-10

spray gun lube to threads. Fluid needle

spring (14) and air valve spring (19) should

be coated with a very light grease, making

sure that any excess grease will not clog

the air passages. For best results, lubricate

the points indicated, daily.

*Not for air tools or high RPM equipment.

A. Trigger Points

B. Packing

C. Adjusting Knobs

D. Baffle Threads

E. Air Valve Cartridge

PARTS REPLACEMENT

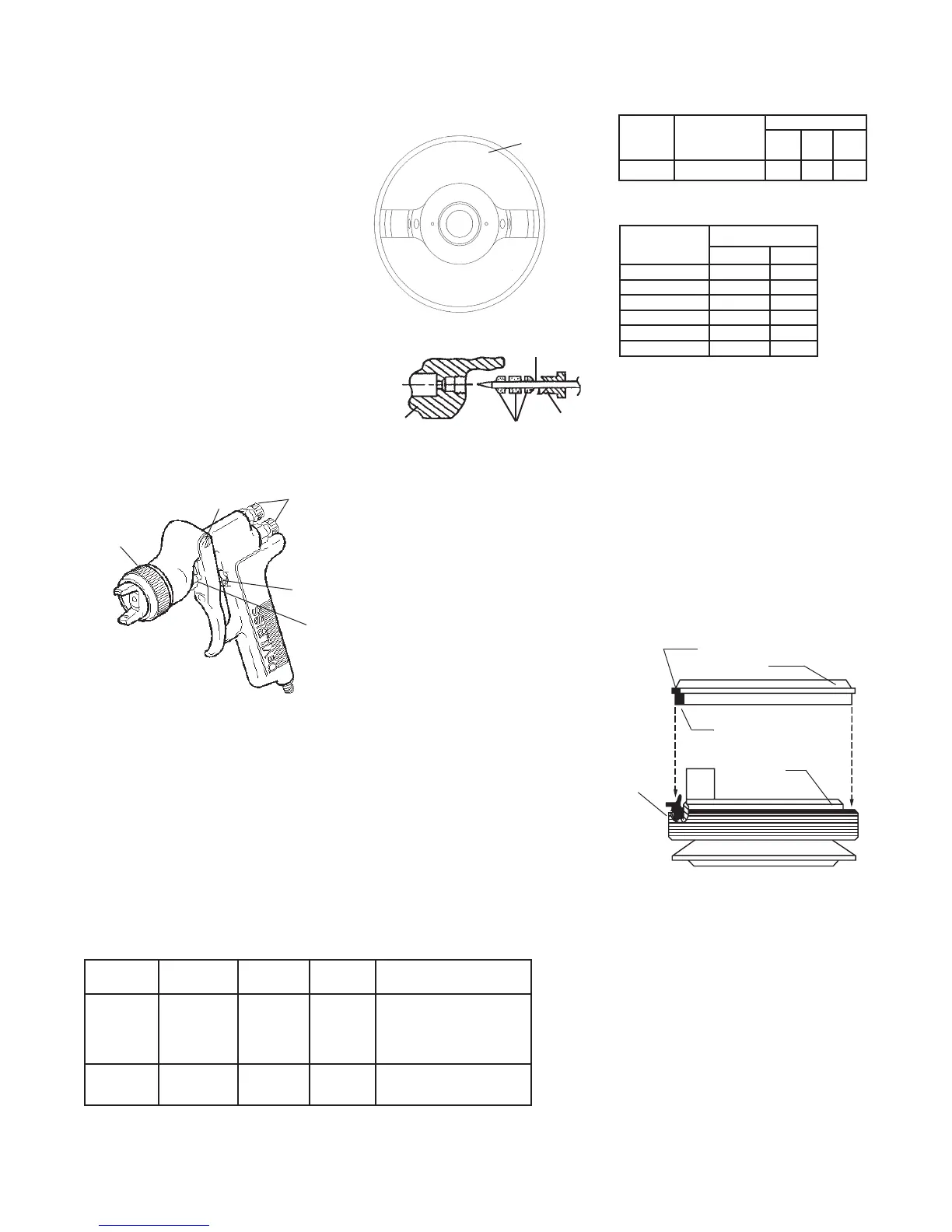

Figure 1 Air Cap

Chart 3

Chart 2

Packing

(3 pieces)

Packing

Nut

Needle

Gun Body

A

B

C

E

D

Air Cap No.

410

DeVilbiss

No. on Air Cap Air Flow (CFM)

Air Cap With Ring @30 @40 @50

Order ➔ (Ref. No. 4) psi psi psi

410 AV-440-410 9.1 11.2 13.2

GTI-33 Baffle Seal Replacement

1. Remove Fluid Tip (5).

2. Remove baffle (6).

3. Remove Seal (7) from baffle.

NOTE

The seal is designed to be a tight

fit on the baffle. The seal should

be able to be removed using your

fingers. If you are unable to remove

the seal using your fingers, insert

a small screwdriver between the

outer lip and the back of the baffle

and pry the seal off.

4. Assemble seal to baffle with angled side

up as shown above. NOTE: The seal

should be a tight fit on the baffle. If it is a

loose fit on the baffle, assure that it is

assembled with the angled side up.

5. Install baffle on gun.

6. Install fluid tip (5) and tighten to

15-20 ft-lbs.

ANGLED SIDE

THICK SIDE

SEAL

BAFFLE

Pry here if

necessary

Fluid Tip Inlet Air

Order No. Model No. (mm) Pressure Applications

110264 GFG-670* 1.2 & 1.3 25-35 psi Base coats

30-40 psi High solids clearcoats

30-40 psi Single stages

25-30 psi Waterbornes

1.4 30-40 psi Low solids clear coats

30-40 psi Single stages

*Includes 1.2 mm, 1.3 mm and 1.4 mm fluid tips

Chart 1

Loading...

Loading...