Page 7SB-6-HGB-P

SERVICE CHECKS

CONDITION CAUSES REMEDES

Regulated pressure creep.

Improper seating of valve stem on seat. Be sure that seat and ball valve are not damaged,

worm or dirty.

Diaphragm leaking. Replace.

Regulated pressure drop.

Restriction in main material line or at

valve seat inlet.

Clear l'obstruction

Diaphragm damaged. Replace.

Fluid leakage from under

bonnet.

Loose cap screws. Screw the 6 screws at a torque 8 mN.

Diaphragm damaged. Replace.

EC DECLARATION OF CONFORMITY

We, Finishing Brands, as the manufacturer of the fluid regulators HGB-509, HGB-510, HGB-609, declare under our sole

responsibility, that the equipment to which this document relates is in conformity with the following standards or other normative

documents :

EN 292-1 PARTS 1 & 2: 1991, EN 1953: 1999; and thereby conform to the requirements of; Council Directive 98/37/EC relating to

Machinery Safety Directive.

These regulators are classed as components, by the ATEX directive 94/9/EC “Equipment and Protective Systems intended for

use in Potentially Explosive Atmospheres” and are in conformity with the provisions of the directive, protection level II 2 G.

Chuck McCulloch, Finishing Brands

March 18, 2014

Finishing Brands reserve the right to modify equipment specification without prior notice.

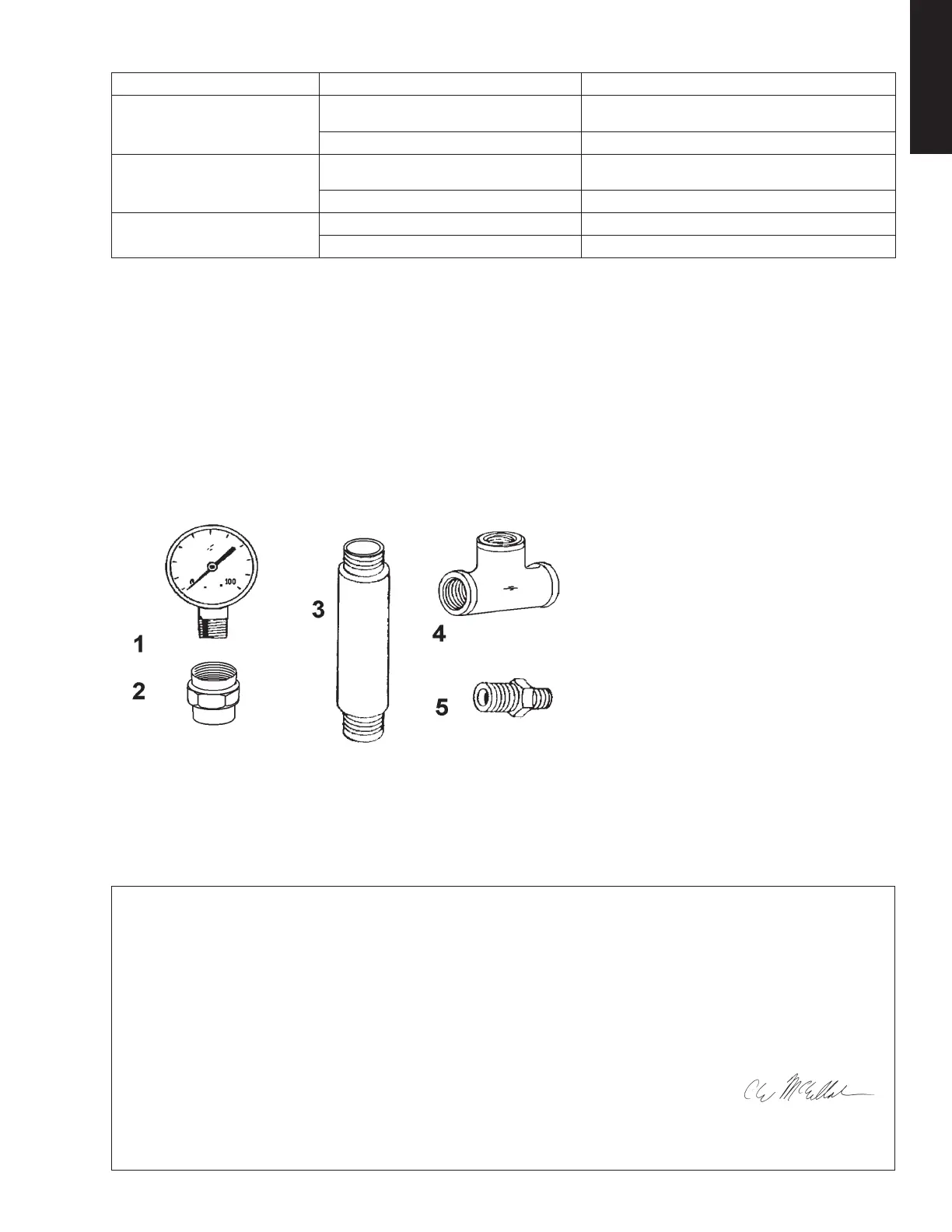

ACCESSORIES

1 MA-25, GA-333, GA-288 : Manometer 2.5b, 6b or 10bar.

2 S-3008 : Stainless steel adapter 1/4’’ BSP female / female

3 S-3007 : Stainless steel riser tube 1/4’’BSP – male/male

4 S-3006 : Tee in stainless steel 1/4’’ BSP – Female

5 HGB-66 : Stainless steel reducer 1/4’’x 3/8 ‘’ BSP male/male (no retention)

S-3009 : Stainless steel coupling 1/4’’BSP Male/Male

ENGLISH

Loading...

Loading...