MAINTENANCE & TROUBLESHOOTING PAGE 5

MAINTENANCE & TROUBLESHOOTING PAGE 5

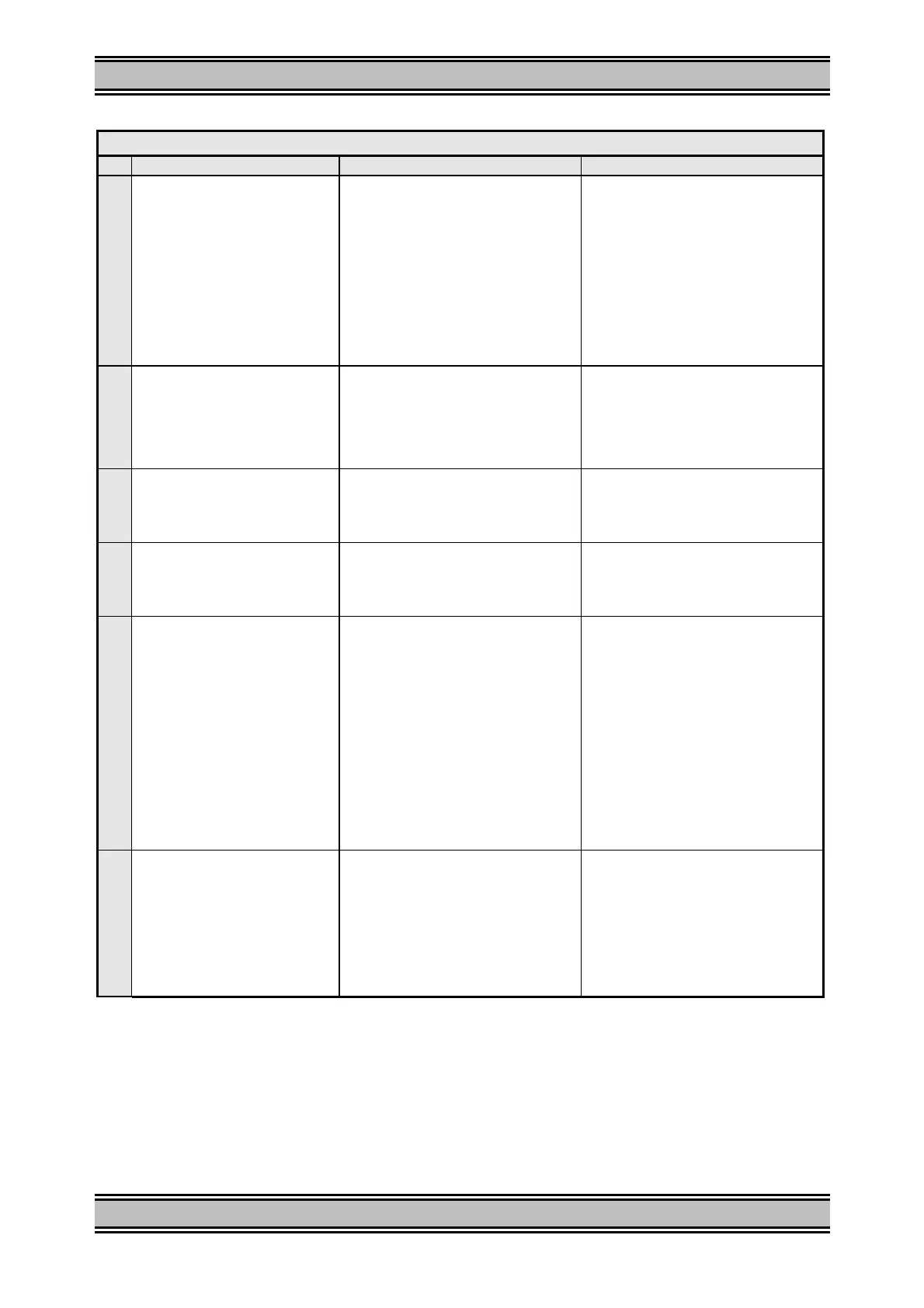

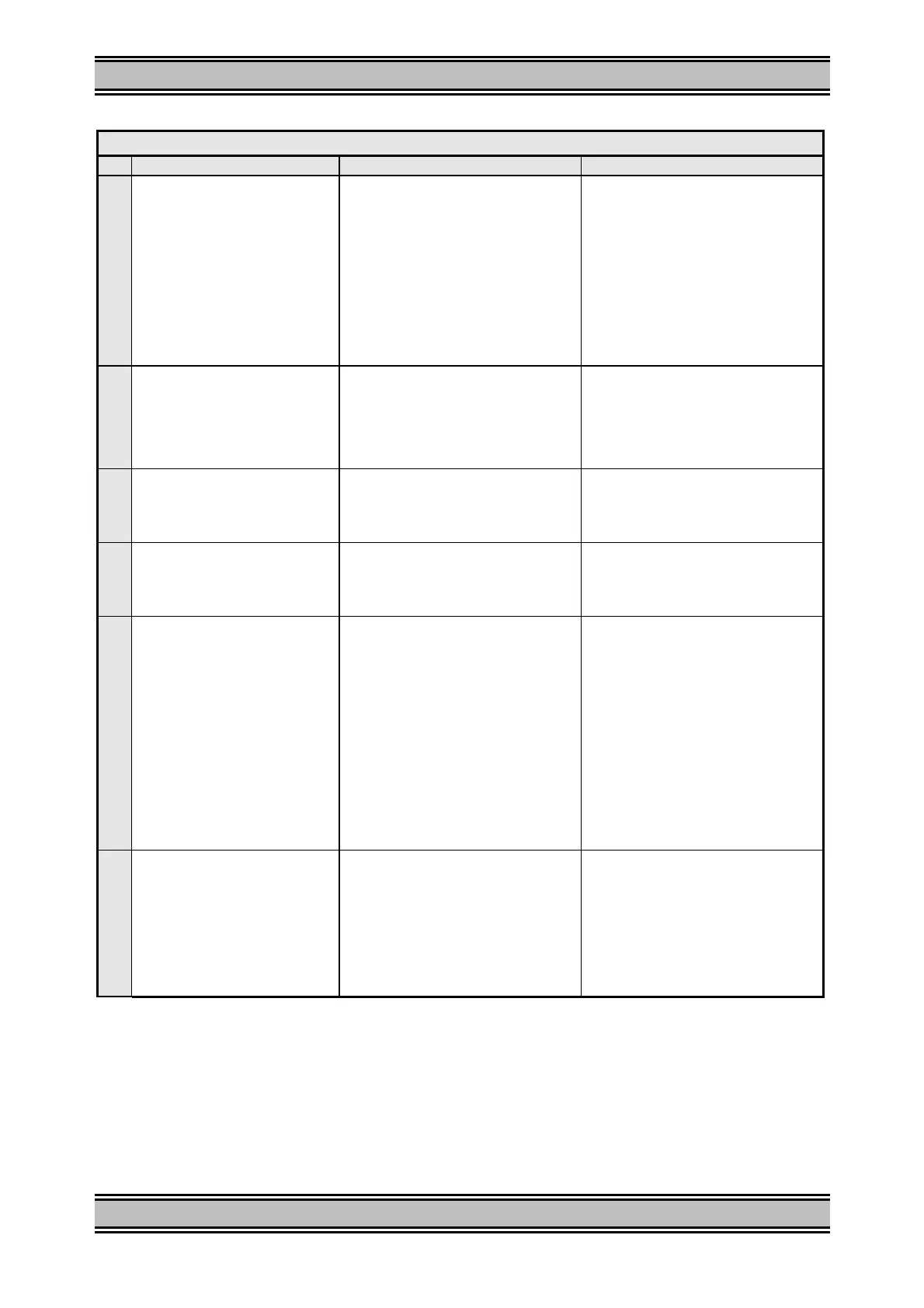

GUN FAULTS

Condition Cause Correction

A

Will not spray No air pressure at gun

Internal mix or pressure feed air cap used

with suction feed

Fluid pressure too low with internal mix

cap and pressure tank

Fluid needle adjusting screw not open

enough

Fluid too heavy for suction feed

Check air supply and air lines

Change to proper suction feed air cap

Increase fluid pressure at tank

Open fluid needle adjusting screw

Thin material or change to pressure feed.

A

Gun ‘spits’ paint when triggering on

and off

Incorrect needle fitted to gun

Excessive needle wear

Excessive fluid tip wear

Check tip/needle selection chart and fit

correct item

Replace with new needle

Replace with new fluid tip

A

Small air leak from air cap when

gun is not triggered

Air valve contaminated and not correctly

seating

Air Valve seal damaged or missing

Remove valve and thorougly clean valve

shaft and seating surfaces

Replace

A

Gun ‘spits’ paint when triggering on

due to paint build-up inside air cap

between spraying operations

Fluid tip not fitted correctly in gun head

Fluid tip/needle leakage

Tighten to correct torque

Check for damage or blockage

B

Slow fluid leak from fluid tip and

needle seat

Fluid Tip internal seat scored, damaged or

worn

Fluid needle external profile damaged or

worn

Contamination on needle or tip mating

surfaces preventing good seal

Incorrect fluid tip for fluid needle fitted to

gun

Sluggish needle

Tight packing nut

Replace

Replace

Thoroughly clean

Check tip/needle selection chart and fit

correct item

Lubricate packing

Adjust

B

Major fluid leak or fluid jetting from

fluid tip and needle seat

Contamination on needle or tip mating

surfaces preventing good seal

Incorrect fluid tip for fluid needle fitted to

gun

Fluid needle stuck or ‘binding up’

Remove tip and needle and thoroughly

clean

Check tip/needle selection chart and fit

correct item

Remove and clean fluid needle shaft, or

lubricate needle packing or loosen needle

packing

Loading...

Loading...