ENGLISH

16

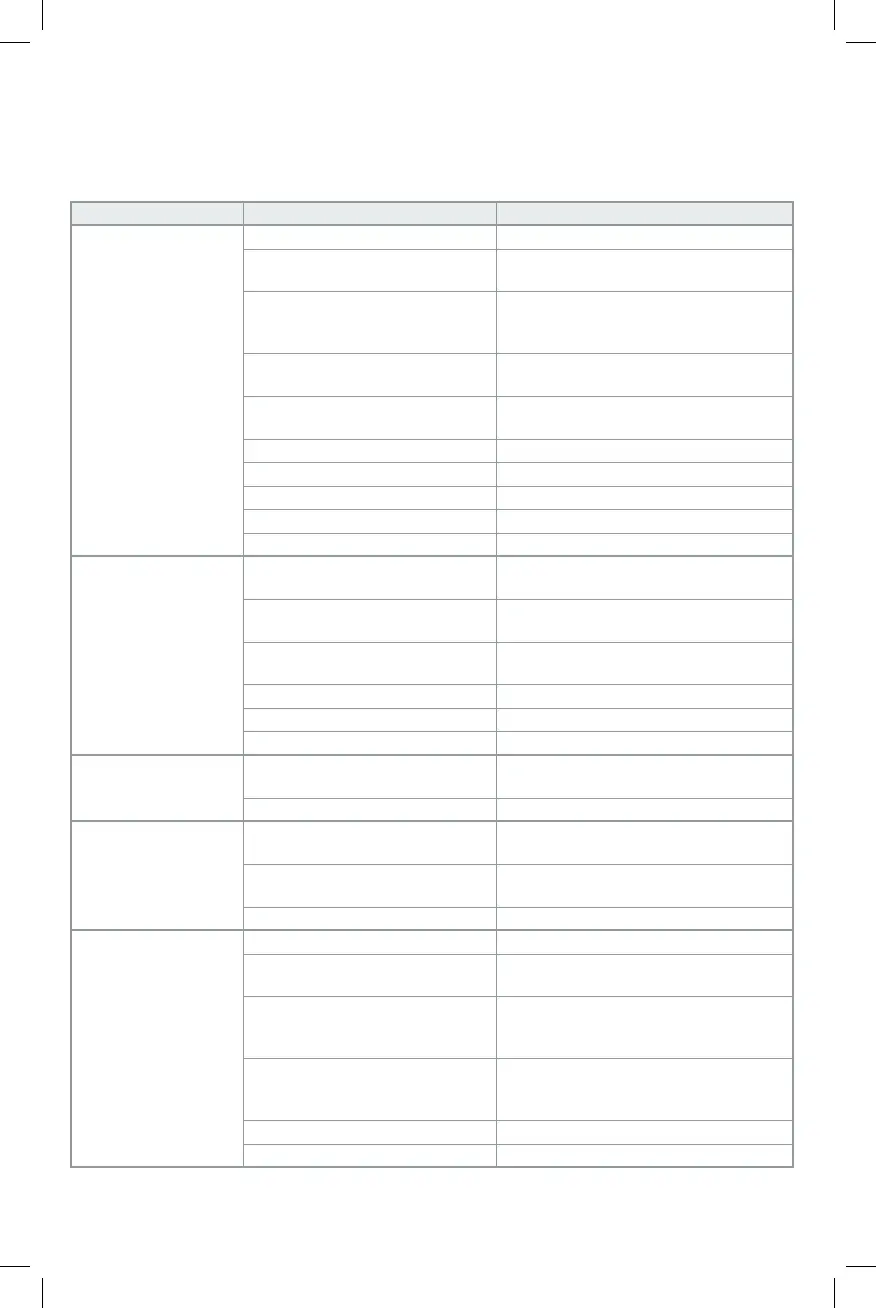

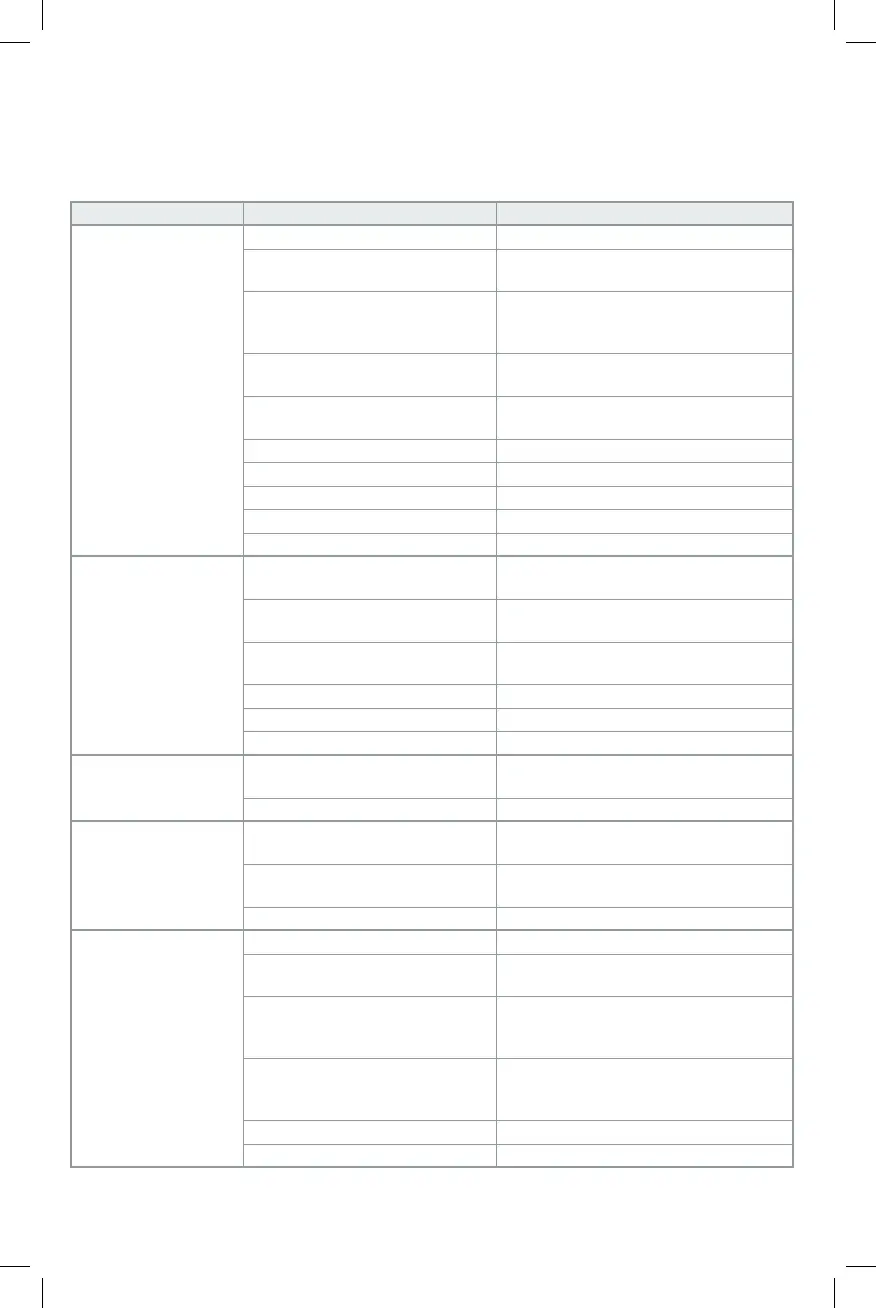

TROUBLESHOOTING GUIDE

Many common problems can be solved easily by utilizing the chart below. For more serious or persistent problems,

contact a

service center or call 1-(800)-4-

.

WARNING: To reduce the risk of serious personal injury, ALWAYS disconnect battery pack from tool before

all repairs.

SYMPTOM CAUSE FIX

Motor does not run with contact

trip depressed

Trigger lock in locked position. Unlock trigger lock.

Dryfire lock out engaged, blocking contact trip from

traveling fully.

Load more pins into magazine.

Tool is stalled, locking the motor from rotating. Rotate the stall release lever on the tool and the mechanism

will release. If driver does not return, remove battery and

manually push driver back to home position.

Battery is hot. (Check LED indicator to verify

these conditions.)

Let the battery cool or replace it with a cool pack.

Tool is hot. (Check LED indicator to verify

these conditions.)

Let the tool cool down before continuing use.

Bent contact trip. See authorized service center.

Motor stops running after 5 seconds. Normal operation, release contact trip and redepress.

Terminals are dirty or damaged. See authorized service center.

Damaged internal electronics. See authorized service center.

Damaged Trigger. See authorized service center.

Tool does not actuate (motor runs

but will not fire)

Dryfire lock out engaged, blocking contact trip from

traveling fully.

Load pins into magazine.

Low battery charge or damaged battery. Check charge level if pack shows state-of-charge. Charge or

replace battery pack if necessary.

Jammed nail/drive blade not returned to

home position.

Remove battery, clear jammed nail, cycle stall release lever,

(push driver up manually if necessary) reinsert battery pack.

Damaged driver. Replace driver with kit.

Jammed internal mechanism. See authorized service center.

Damaged internal electronics. See authorized service center.

Motor starts up but generates a

lot of noise

Jammed pin and driver is stuck in down position. Use stall release lever, clear and jammed pins, and return

driver manually if necessary.

Damaged driver. Replace driver with kit.

Driver blade continues to get stuck

in down position

Jammed pin and driver is stuck in down position. Use stall release lever, clear any jammed pins, and return

driver manually if necessary.

Debris in nosepiece. Clean nose area and watch closely for small pieces of broken

pins stuck in the track. Refer to Clearing a Jammed Pin.

Damaged or worn driver. Replace driver with kit.

Tool operates but does not drive

fasteners fully

Power setting in wrong position. Set power to appropriate setting.

Tool not firmly applied to workpiece. Apply adequate force to tool securing it tightly to workpiece.

See instruction manual.

Material and fastener length. If the unit continues to stall (forcing the need to rotate the

stall release lever) choose the appropriate material and

fastener length that is not too rigorous of an application.

Use of incorrect power setting. If trying to drive longer pins in soft woods, or driving pins

into harder materials using power setting 1 - adjust power

setting to 2.

Damaged or worn driver tip. Replace driver with kit.

Damaged actuation mechanism. See authorized service center.

Loading...

Loading...