ENGLISH

10

tool. This can seriously affect the life and performance

of thetool.

NOTE: The battery pack is not fully charged out of the

carton. Follow instructions outlined (refer to Charging

ABattery).

1. Read the Nailer Safety Warnings section of

thismanual.

2. Wear eye and earprotection.

3. Remove battery fromtool.

4. Ensure magazine is empty of allfastners.

5. Check for smooth and proper operation of contact

trip and pusher assemblies. Do not use tool if either

assembly is not functioning properly. NEVER use

a tool that has the contact trip restrained in the

actuatedposition.

6. Keep tool pointed away from yourself andothers.

7. Insert fully charged batterypack.

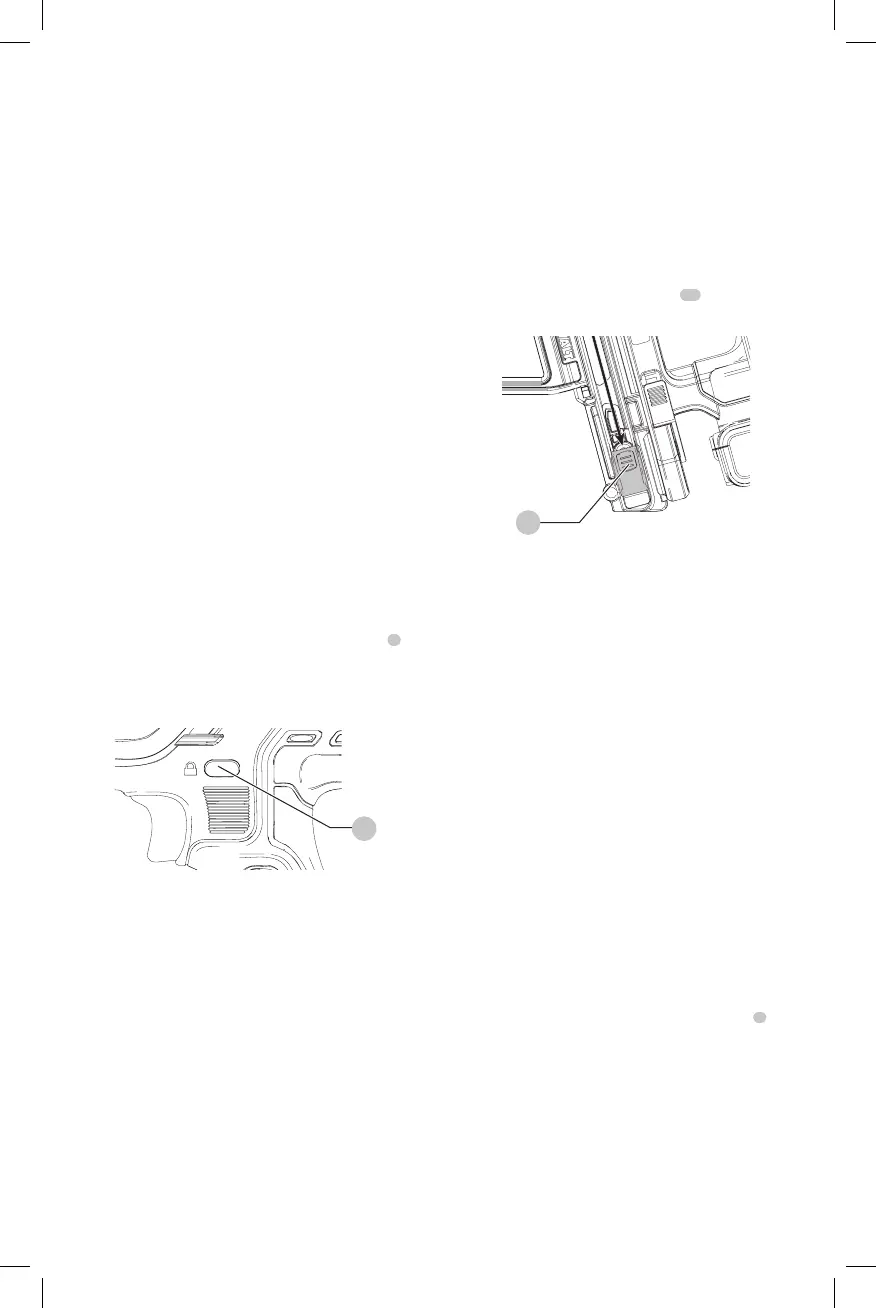

Using the Trigger Lock-off (Fig. F)

WARNING: To reduce the risk of serious personal

injury, do not keep trigger depressed when tool is not

in use. Keep the trigger lock-off switch LOCKED (Fig.F)

when the tool is not inuse.

WARNING: To reduce the risk of serious personal

injury, lock off trigger, disconnect battery pack

from tool and remove pins from magazine before

makingadjustments.

Each

nailer is equipped with a trigger lock-off

2

which when pushed to the right as shown in FigureF,

prevents the tool from firing a pin by locking the trigger and

bypassing power to themotor.

Fig. F

2

When the trigger lock-off is pressed to the left, the tool will

be fully operational. The trigger lock-off should always be

locked off whenever any adjustments are made or when

tool is not in immediateuse.

NOTICE: Do not store tool with battery pack installed.

To prevent damage to the pack and to ensure best

battery life, store battery packs out of the tool or

charger in a cool, drylocation.

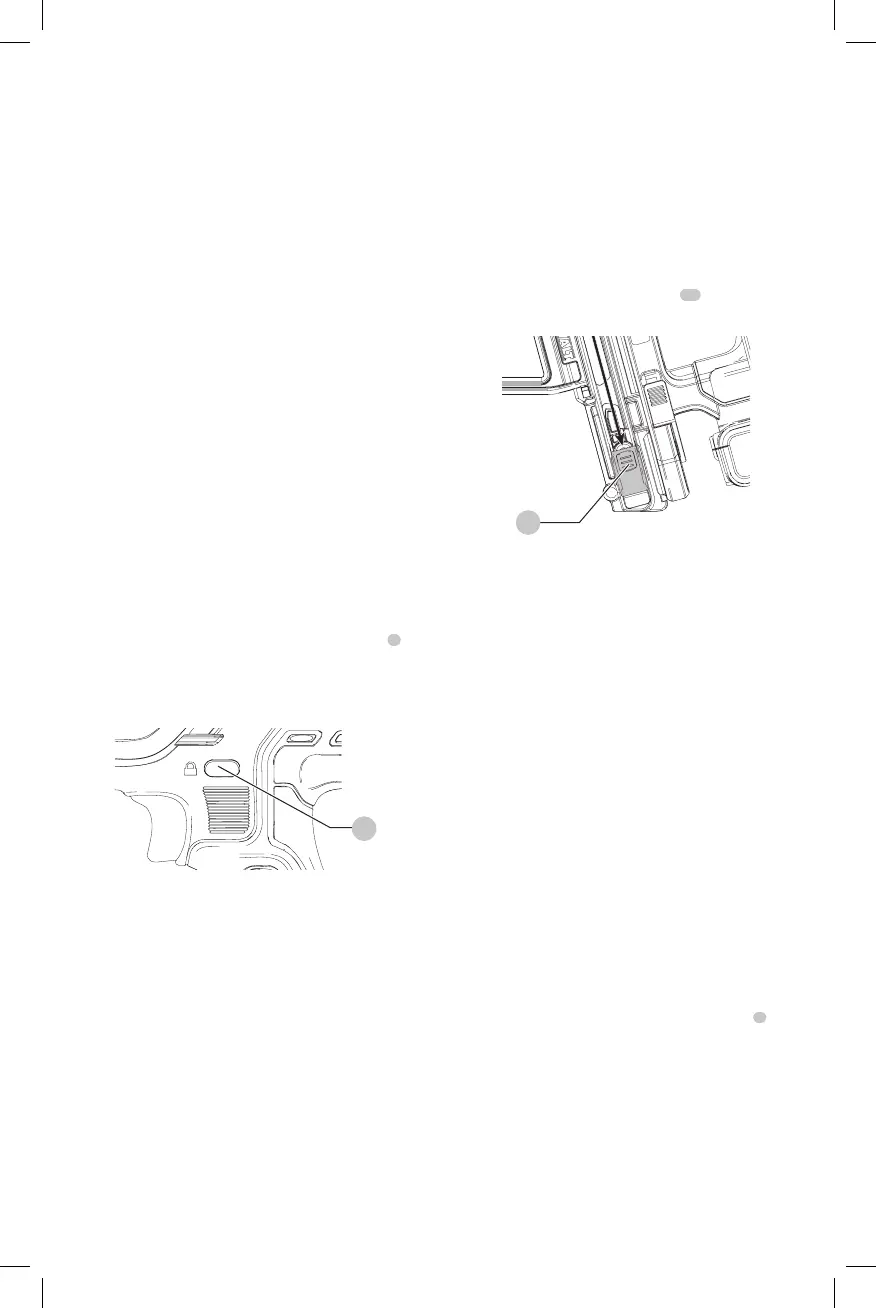

Loading the Tool (Fig. G)

WARNING: Keep the tool pointed away from yourself

andothers.

WARNING: Never load pins with the contact trip or

triggeractivated.

WARNING: Always remove battery pack before

loading or unloadingpins.

CAUTION: Keep fingers clear of pusher latch track to

preventinjury.

WARNING: The trigger lock-off should always be

engaged whenever any adjustments are made or

when tool is not inuse.

WARNING: Fasteners used to install metal connectors

must meet the requirements of the applicable building

codes and must be installed in compliance with code

requirements and metal connector hardware supplier

specifications. Failure to properly install connectors

may result in structuralfailures.

1. Turn the nailer upsidedown.

2. Slide the spring-loaded pusher latch

15

to the base of

the magazine to lock it intoplace.

Fig. G

15

3. Drop pin strips into the loading slot of the magazine,

making sure the pin heads align correctly with the slot

opening. (Refer to Pin Specifications to determine

compatible size.)

4. Keeping fingers clear of the track, close the magazine by

releasing the pusher latch. Carefully allow the latch to

slide forward and engage the pinstrip.

Unloading the Tool

WARNING: The trigger lock-off should always be

locked off whenever any adjustments are made or

when tool is not inuse.

1. Slide the spring-loaded pusher latch to the base of the

magazine to lock it intoplace.

2. Tip the tool up until the fastener strip slides freely out of

themagazine.

3. With battery removed, check the nosepiece to verify

there are no pinsremaining.

NOTE: The tool is equipped with a magnet in the nose

area for improved tool performance. When unloading,

always verify that the small sticks of pins are not held to the

magnetized nosepiece.

Power Setting Summary (Fig. H, I)

This nailer is equipped with a power selection switch

3

to

adjust the tool when driving into differentmaterials.

Power setting 1: Softer materials (low strength concrete/

cinder block)

Power setting 2: Medium hardness materials (High strength

concrete)

Power setting 3: Hard materials (Structural Steel)

In the event pins are not driving to depth in power setting1,

you may have to switch to power 2 or 3 for additional

drivingpower.

Loading...

Loading...