ENGLISH

11

4. Release the trigger and raise the nailer from the

worksurface.

NOTE: The tool motor returns to full speed

automatically without the contact trip

6

beingdepressed.

5. Repeat steps 2–4 to actuate the nextnail.

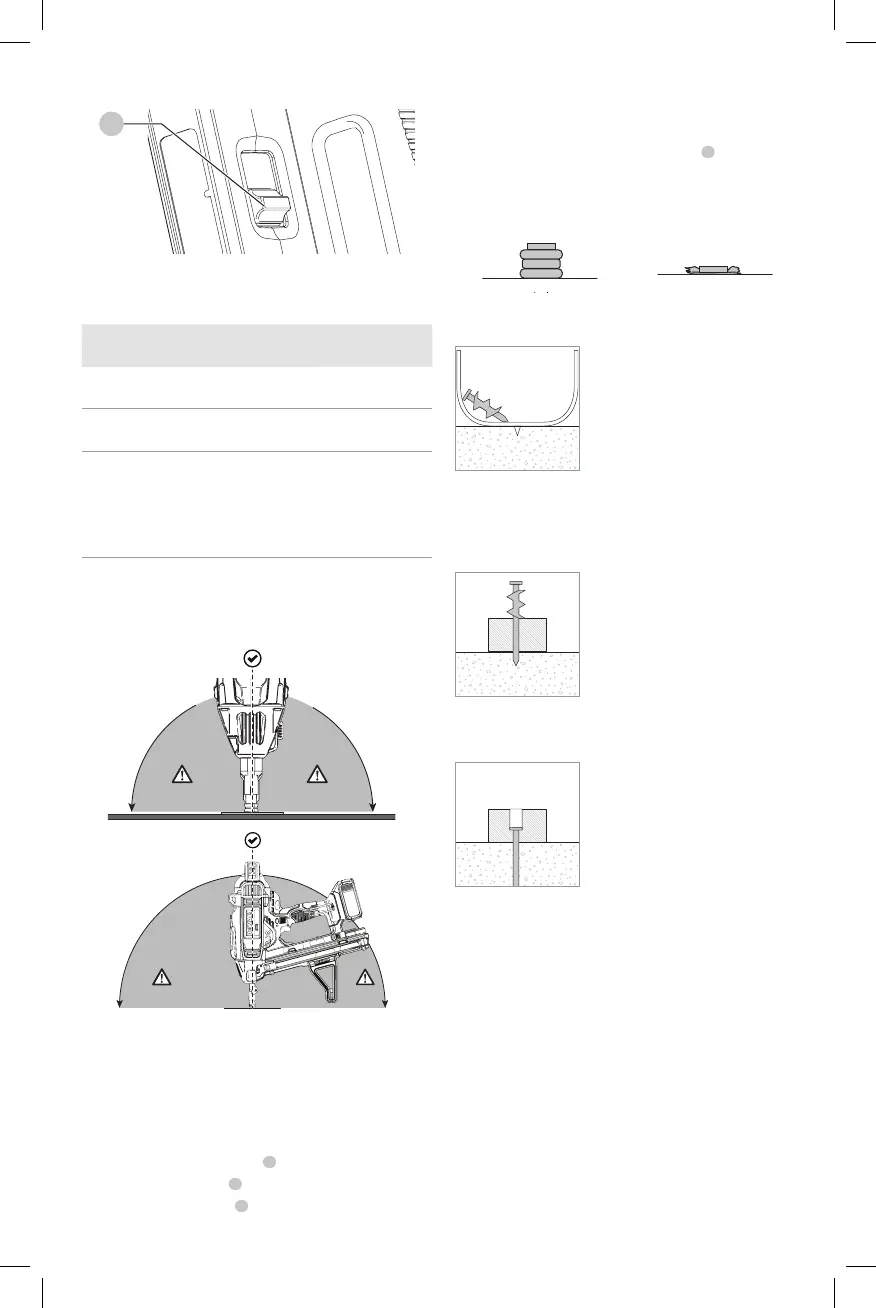

Pin/Fastener Troubleshooting

Properly driven pin Over driven pin

CONCRETE

Pin does not hold in the concrete.

Cause:

- Too hard/high

strengthconcrete.

- Hard or large aggregate

inconcrete.

Action:

- Use shorter pin.

- Switch to higher

powersetting.

Pin does not drive deep enough.

Cause:

- Pin too long.

- Power setting too low.

Action:

- Use shorter pin.

- Switch to higher

powersetting.

Pin drives too deep.

Cause:

- Pin too short for application.

- Power setting too high.

Action:

- Use longer pin.

- Switch to lower

powersetting.

Fig. H

3

NOTICE: Driving pins into soft materials at high

power settings will cause excessive wear to your

tool and may result in early failures.

Power

Setting

Application Typical Pin Length

1

Fastening to Low Strength Concrete/

Masonry (<4000 psi)

3/4" to 1-1/4" typ.

2

Fastening to High Strength Concrete

(>4000 psi)

3/4" to 1" typ.

3

Fastening to High Strength Concrete

(>4000 psi)

Fastening to structural steel;

Fastening through plywood, insulation,

or fixture

1/2" to 2-1/4" typ.

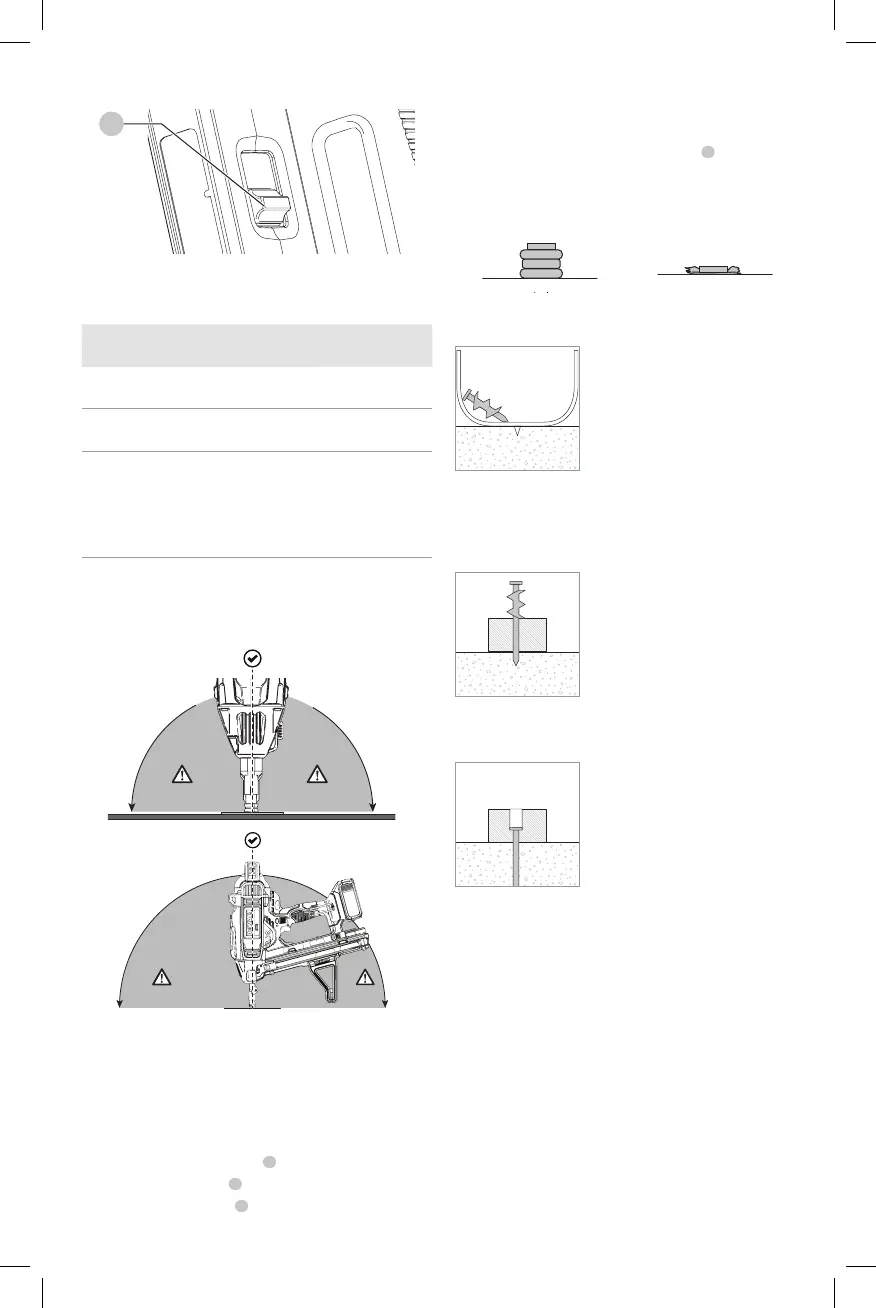

WARNING: Pins must be driven straight into the

material. Do not tilt nailer while driving fasteners.

Refer to Fig.I. Pin retention values improve when the

tool is fired perpendicular to the material.

Fig. I

Actuating the Tool (Fig. A)

WARNING: Always wear proper eye [ANSI Z87.1

(CAN/CSA Z94.3)] and ANSI S12.6 (S3.19) hearing

protection when operatingtool.

The motor rotation speed is automatically restored after

driving a pin to allow fast consecutive nailing.

1. Release the trigger lock-off

2

.

2. Push the contact trip

6

against the worksurface.

3. Pull the trigger switch

1

to actuate thetool.

Loading...

Loading...