ENGLISH

12

Pin bends.

Cause:

- Pin hit large aggregate

onentry.

- Too hard/high

strengthconcrete.

- Pin hit rebar just

undersurface.

Action:

- Use shorter pin.

- Make sure nailer is

perpendicular to the

worksurface.

- Move 3" (8 cm) and

tryagain.

STEEL

Pin does not penetrate the surface.

Cause:

- Power setting too low.

- Material to hard for

pintype.

Action:

- Increase tool power setting.

Pin breaks or bends.

Cause:

- Pin too long.

- Power setting too low.

- Material to hard for

pintype.

Action:

- Use shorter pin.

- Switch to higher

powersetting.

Pin does not hold in the steel.

Cause:

- Steel base material too thin.

Action:

- Use thicker base material.

Headlights/LED Indicator (Fig. A)

There are low battery and jam/stall indicator lights

9

located on the front of the tool on each side of

themagazine.

LOW BATTERY

Replace battery with a charged pack.

HOT PACK

Let the battery cool or replace it with

a cool pack.

JAM/STALL CONDITION

Rotate the stall release lever

torelease.

Refer to Stall Release or Clearing a

Jammed Pin.

HOT TOOL (Both LEDs Flashing)

Let the tool cool down before

continuing use.

or any other

combination.

ERROR

Reset tool by removing and

reinserting battery pack or cycling

trigger lock off. If error code persist,

take tool to an authorized

service center.

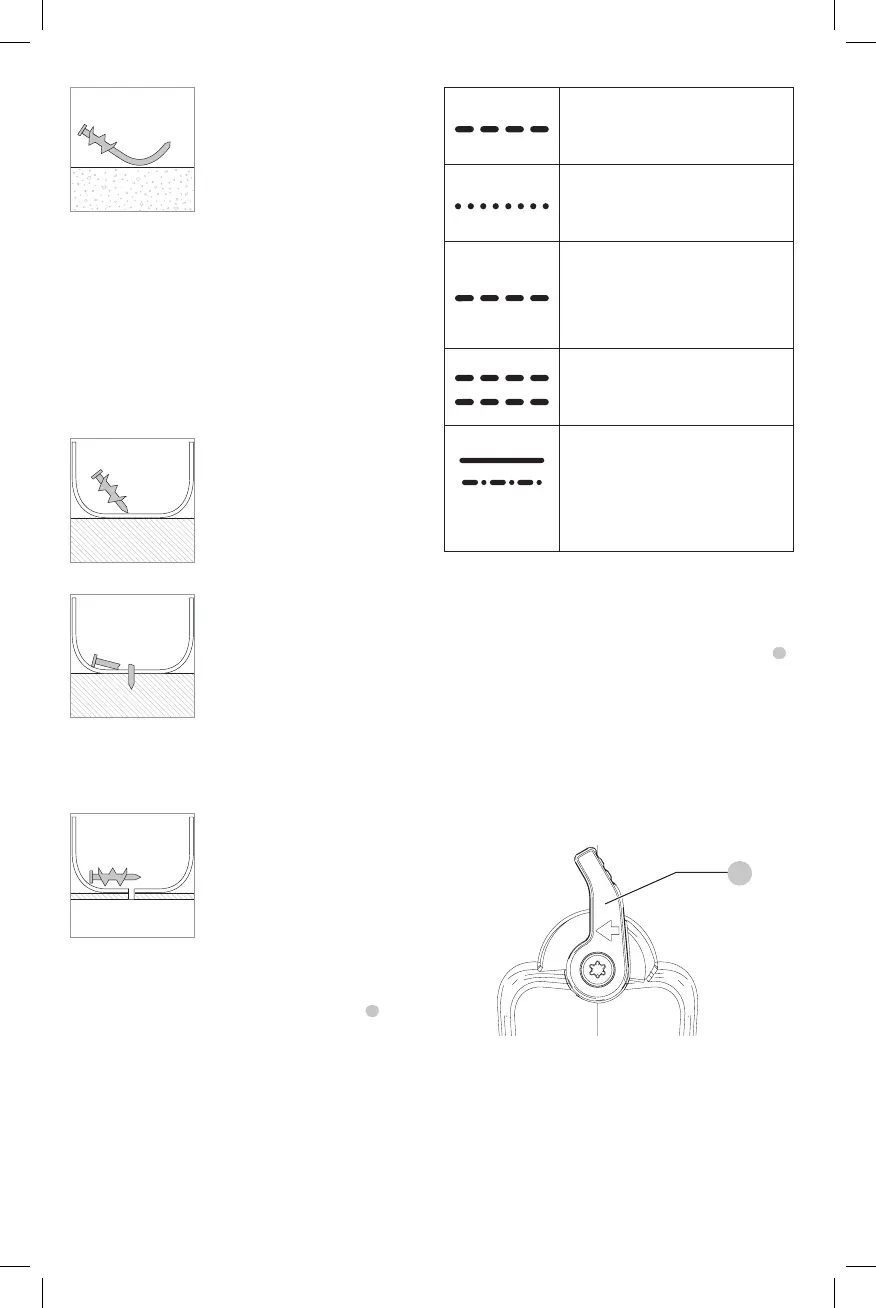

Stall Release (Fig. J)

If the nailer is used in harder material where all available

energy in the motor is used to drive a fastener, the tool may

stall. The driver will not complete the drive cycle and the

jam/stall indicator will flash. Rotate the stall release lever

8

on the tool and the mechanism will release.

NOTE: The tool will disable itself and not reset until the

battery pack has been removed and reinserted. If the

driver does not automatically return to the home position,

proceed to Clearing a Jammed Pin. If the unit continues

to stall please review the material and fastener length to

be sure that it is not too rigorous an application. The nailer

could also be overheated and needs time to cool before

further use.

Fig. J

8

Clearing a Jammed Pin (Fig. A, K)

WARNING: To reduce the risk of serious personal

injury, disconnect battery pack from tool before

making any adjustments, changing accessories,

servicing, or moving the tool. Such preventative

safety measures reduce the risk of starting the

toolaccidentally.

CAUTION: When removing a jammed pin, DO

NOT orient the nailer with the nose up or with

Loading...

Loading...