English

4

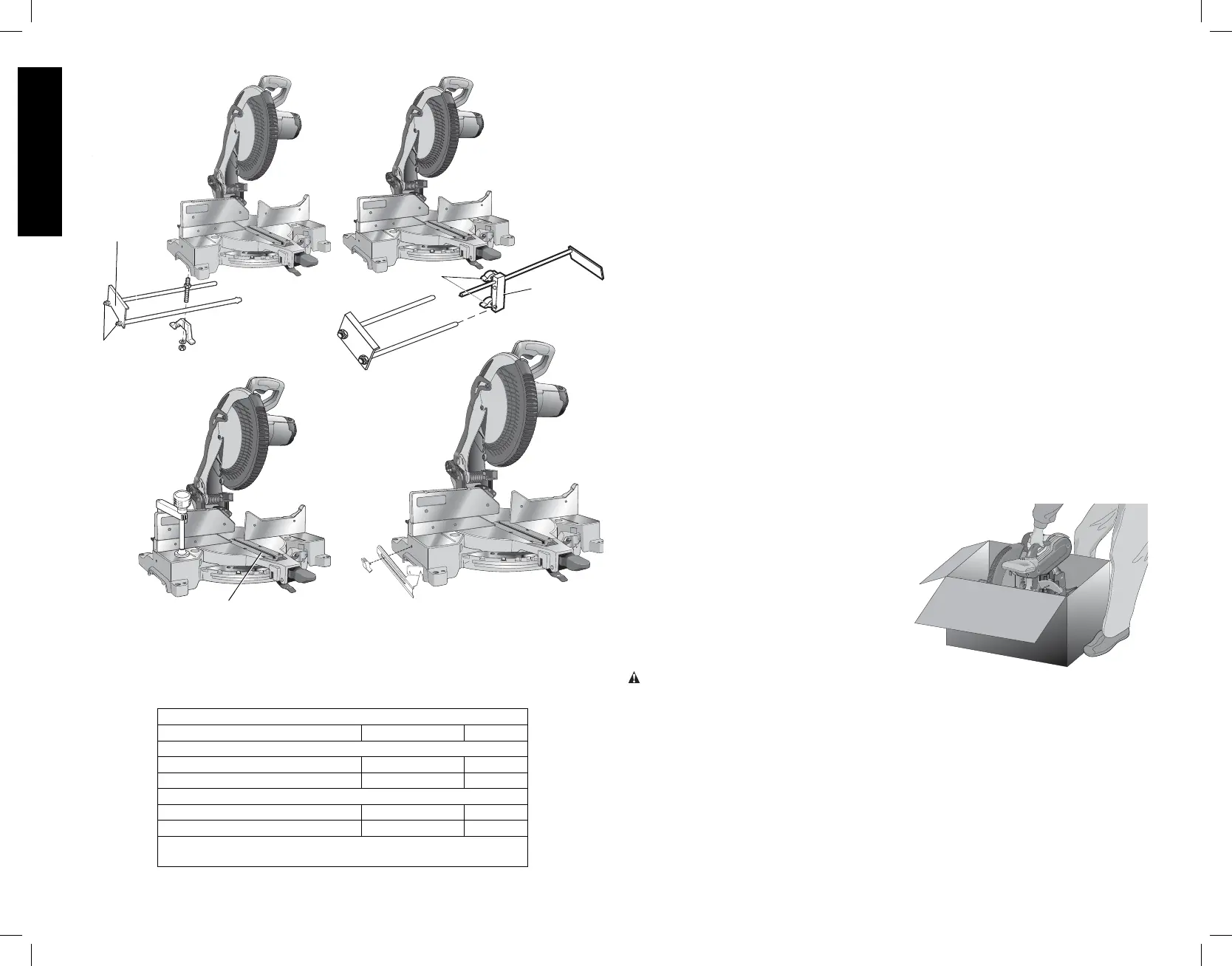

DW7080

END

PLATE

LOCK

NUTS

DW7084

DW7082

FIG. 1

DW7051

KNOBS

BRACKET

DW7055

SAW BLADES: ALWAYS USE 12" (305 mm) SAW BLADES WITH 1" (25.4 mm) ARBOR

HOLES. SPEED RATING MUST BE AT LEAST 4800 RPM. Never use a smaller diameter

blade. It will not be guarded properly. Use crosscut blades only! Do not use blades designed

for ripping, combination blades or blades with hook angles in excess of 7˚.

BLADE DESCRIPTIONS

APPLICATION DIAMETER TEETH

Construction Saw Blades (thin kerf with anti-stick rim)

General Purpose 12" (305 mm) 40

Fine Crosscuts 12" (305 mm) 60

Woodworking Saw Blades (provide smooth, clean cuts)

Fine crosscuts 12" (305 mm) 80

Non-ferrous metals 12" (305 mm) 96

NOTE: For cutting non-ferrous metals, use only saw blades with

TCG teeth designed for this purpose.

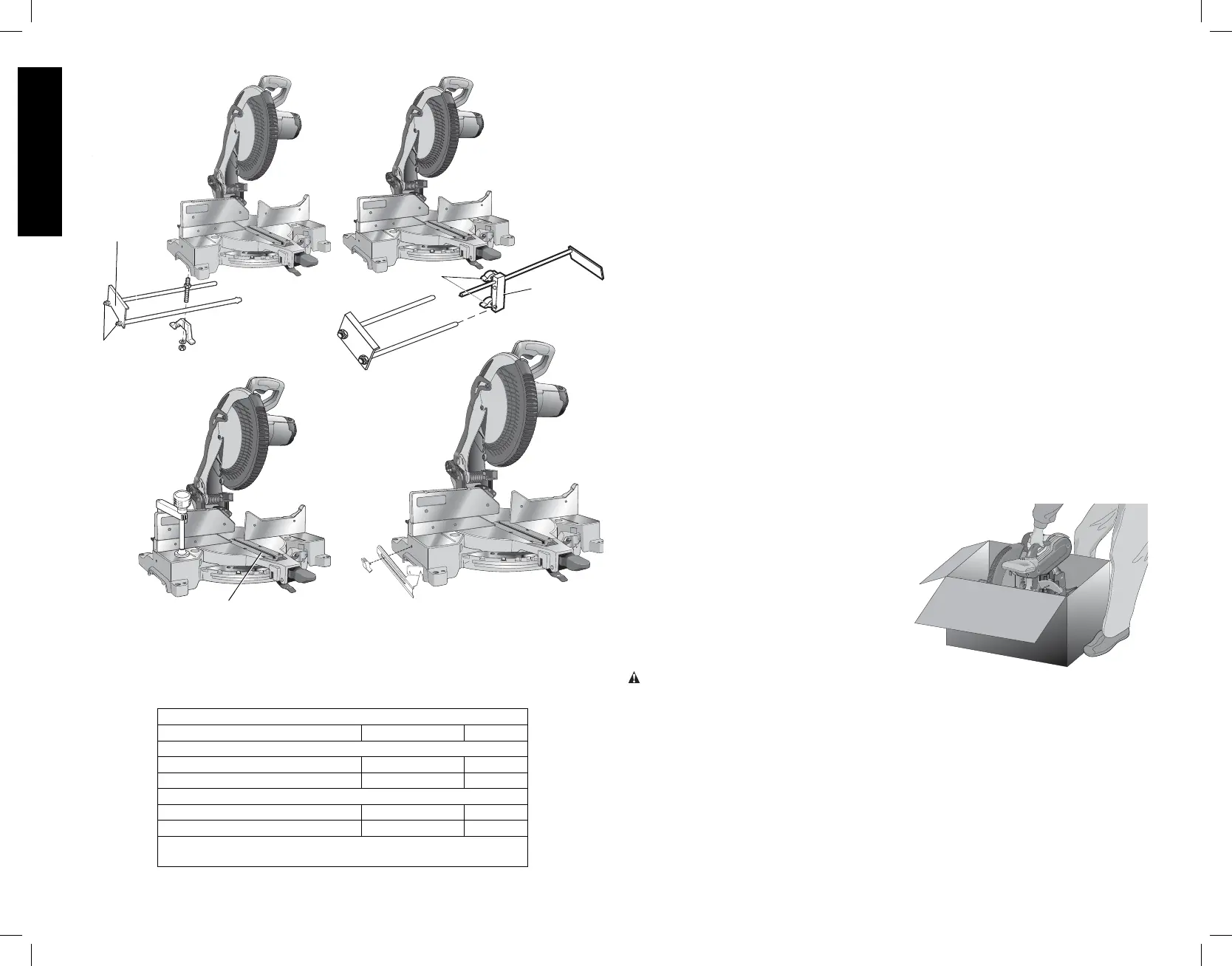

Unpacking Your Saw

Check the contents of your miter saw carton to make sure that you have received all parts. In

addition to this instruction manual, the carton should contain:

• One No. DW715 miter saw.

• One D

EWALT 12" (305 mm) dia. saw blade

• One blade wrench in wrench pocket shown in Figure 2.

• One DW7053 dustbag (some models).

Specifi cations

CAPACITY OF CUT

50° miter left and right

48° bevel left, 3° bevel right

0° miter

Max. Height 3.5" (89 mm) Result Width 6.5" (165 mm)

Max. Width 7.7" (196 mm) Result Height 2.6" (66 mm)

45° miter

Max. Height 3.5" (89 mm) Result Width 4.7" (120 mm)

Max. Width 5.5" (140 mm) Result Height 2.6" (66 mm)

45° bevel - Left

Max. Height 2.3" (58 mm) Result Width 6.7" (170 mm)

Max. Width 7.7" (196 mm) Result Height 1.7" (43 mm)

DRIVE

120 Volt Motor

1600 Watts (max in) 15 Amp Motor

4000 RPM Cut Helical Gears

Roller Bearings Carbide Blade

Automatic Electric Brake

Familiarization

Your miter saw is fully assembled in the carton.

FIG. 1A

Open the box and lift the saw out by the

convenient carry ing handle, as shown in

Figure 1A. Place the saw on a smooth, flat

surface such as a workbench or a strong table.

Examine Figure 2 to become familiar with

the saw and its various parts. The section on

adjus tments will refer to these terms and you

must know what and where the parts are.

CAUTION: Pinch Hazard. To reduce the risk of injury, keep thumb underneath the handle

when pulling the handle down. The lower guard will move up as the handle is pulled down

which could cause pinching. The handle is placed close to the guard for special cuts.

Press down lightly on the operating handle and pull out the lock down pin, as shown in Figure 2.

Gently release the downward pressure and hold the arm allowing it to rise to its full height. Use

the lock down pin when carrying the saw from one place to another. Always use the carrying

handle to transport the saw or the hand indentations shown in Figure 2 and 4.

Bench Mounting

Holes are provided in all four feet to facilitate bench mounting, as shown in Figure 2. (Two

different sized holes are provided to accommodate different sizes of screws. Use either hole,

it is not necessary to use both.) Always mount your saw firmly to a stable surface to prevent

movement. To enhance the tool’s portability, it can be mounted to a piece of 1/2" (12.7 mm)

Loading...

Loading...