8

ENGLISH

To Attach the Depth Adjustment Handle (Fig.D1)

1. Insert the depth adjustment handle

3

over theshaft.

2. Secure the depth adjustment handle in place with the screw and hex keyprovided.

Depth Adjustment (Fig.A2, D1–D4)

Your DW733 is equipped with a high precision depth adjustment system including a depth

adjustment scale

8

(Fig.D3), a material removal scale

9

(Fig.D4), a fine adjuster and a depth

stop

15

(Fig.A2).

1. Unlock the head lock lever

2

(Fig.D3) by pulling itup.

2. To attach the depth adjustment handle

3

(Fig.D1). One turn corresponds to a change in

cutting depth of approx. 1.5mm.

- Turn clockwise to decrease the cuttingdepth.

- Turn counterclockwise to increase the cutting depth (Fig.D2).

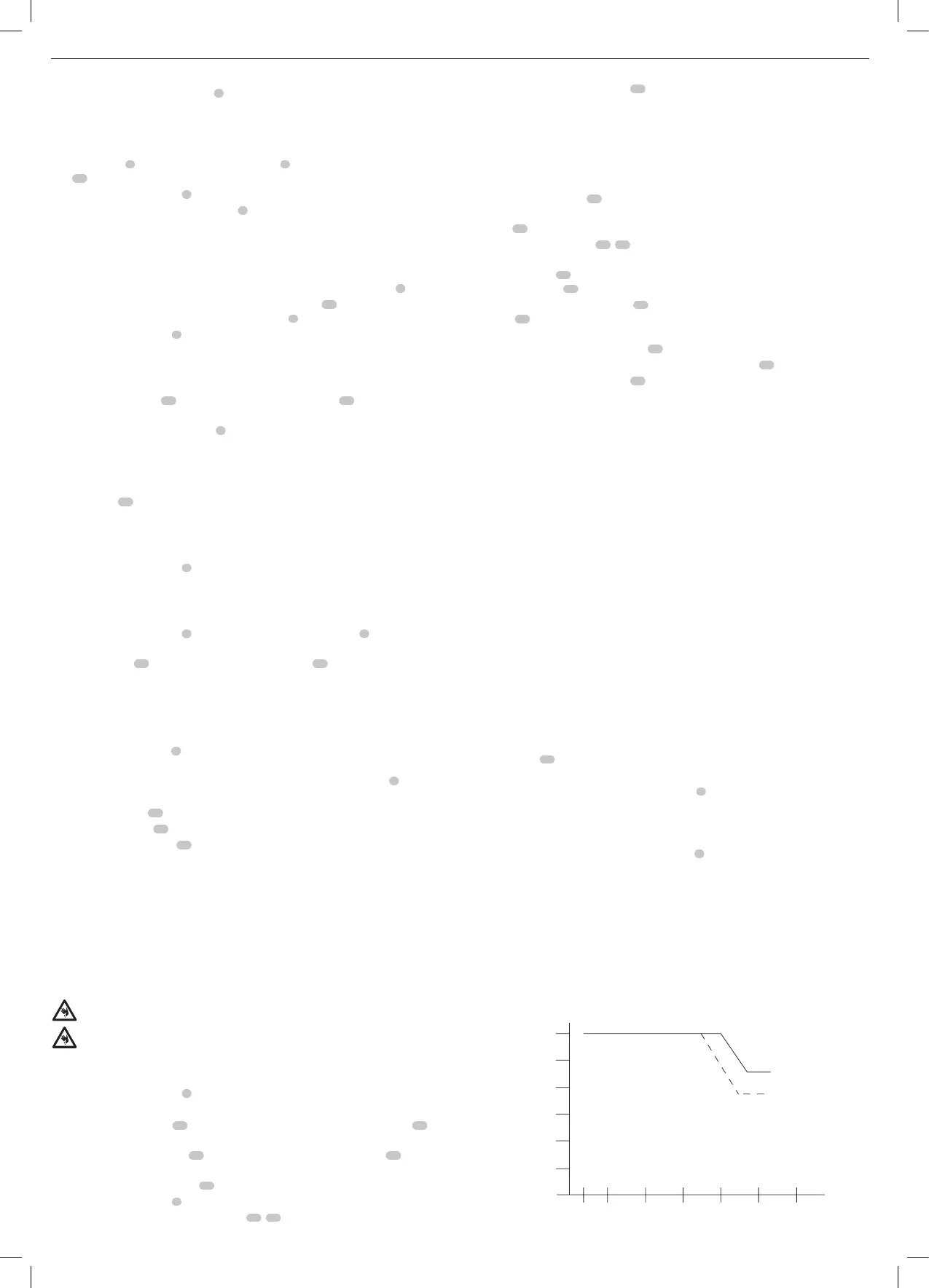

- Observe the setting of the cutting depth and cutting width shown in Fig.G.

3. Read the finished thickness of your workpiece on the depth adjustment scale

8

(Fig.D3).

4. Make sure the material is under the material removal gauge

21

. Read the amount of

wood being removed on the material removal scale

9

(Fig.D4).

5. Lock the head lock lever

2

(Fig.D3).

Fine Adjustment (Fig.D2)

Fine adjustments are ideal for shaving small amounts from planed material. For example, if

your planed workpiece is 77.5 mm and should be 76.0 mm, proceed as follows:

1. Turn the circular label

22

until the 0mark aligns with the arrow

23

. Do not make any

otheradjustments.

2. Turn the depth adjustment handle

3

clockwise until the 1.5 mm mark aligns with

thearrow.

3. Plane your workpiece. The final thickness is now 76.0mm.

Depth Stop (Fig.A2, D3, D5)

The depth stop

15

(Fig.A2) can be used for repetitive planing of preset depths. Stops are set

at 0, 6, 12and 19mm.

Use the 0mm stop for cutting depths between 3.2 and 6mm.

1. Turn the depth stop until the desired measurement isindicated.

2. Unlock the head lock lever

2

(Fig.D3) and turn the depth adjustment handle clockwise

until it contacts the depth stop. Do not turn the handle anyfurther.

Use the 19mm stop for other thicknesses.This will not affect the other

depth stopsettings.

1. Unlock the head lock lever

2

and turn the depth adjustment handle

3

counterclockwise

to raise the headfully.

2. Loosen the nut

24

and adjust the depth adjustment bolt

25

as required (Fig.D5).

3. Turn the depth adjustment handle until it contacts the depth stop. Do not turn the handle

anyfurther.

4. Plane your workpiece and check its thickness. Make additional adjustments ifrequired.

Calibrating the Depth Adjustment Scale (Fig.D3)

The depth adjustment scale

8

is factory set. In the case of extended use, it is recommended to

check the scale foraccuracy.

Plane a piece of wood, noting the measurement on the depth adjustment scale

8

.

If adjustment is required, proceed as follows:

1. Loosen the screws

34

.

2. Adjust the indicator

35

until its reading matches the finished thickness of theworkpiece.

3. Firmly tighten the screws

34

.

Consult your dealer for further information on the appropriate accessories. These include spare

blades (1004540‑00).

Changing Blades (Fig.A1, A2, E1–E5)

WARNING: use only cutting blades designed for thismachine.

WARNING: Wear gloves when changing blades because of sharpedges.

Your DW733 is equipped with a cutterhead which holds twoblades. For new blades contact

or an authorised serviceorganisation.

WARNING: Sharpedges.

WARNING: The blades can be re-sharpenedmax. 3mm down from their original size.

If the blade size has decreased by more than 3mm, the blades have to be replaced. The

blades can be re-sharpened at 42°.

Removing the Blades (Fig.A1, A2, E1–E4)

1. Unlock the head lock lever

2

(Fig.A1).

2. Adjust the depth of cut to approx. 75mm.

3. Loosen the three screws

41

, then rotate and remove the dust extraction adaptor

14

(Fig.A2).

4. Remove the two hex screws

26

(Fig.E1) and carefully remove the tool tray

13

(Fig.A2) to

expose theblades.

5. Carefully rotate the cutterhead

31

(Fig.E4) until the first blade becomesvisible.

6. Lock the head lock lever

2

(Fig.A1).

7. Loosen the seven blade clamping screws (

27

,

29

) (Fig.E2) using the wrenchsupplied.

8. Remove the blade from the cutterhead for re‑sharpening orreplacement.

9. Press the cutterhead locking lever

30

(Fig.E3) and slowly rotate the cutterhead until the

other blade can beremoved.

Replacing the Blades (Fig.E2–E5)

WARNING: Make sure that the cutting blades are properly adjusted. Do not allow the

blades to protrude from the cutterhead by more than 1.1mm.

NOTE: Before installing the knife, ensure the cutterhead and knife are free of debris; clean

ifneeded.

1. Position the cutterhead

31

as shown in FigureE4.

2. Place the blade in the cutterhead and ensure that the head of the height adjustment

screw

28

(Fig.E4) locates into the bladeslot.

3. Loosen the seven screws (

27

,

29

) (Fig.E2) on the blade clamp against the blade a little

bit to allow the blade to be adjusted forheight.

4. Place the gauge

33

(Fig.E4) on the cutterhead as close as possible to the height

adjustment screw

28

while still allowing movement of the hexkey.

5. Turn one height adjustment screw

28

with the hex key until the blade tip touches the

gauge

33

(Fig.E5). Repeat the procedure with the other height adjustment screw. Check

to ensure the blade height is even. Repeat this procedure ifneeded.

6. Tighten the two end clamping screws

29

(Fig.E2) to 8.0Nm.

7. Remove the gauge and tighten the five middle clamping screws

27

(Fig.E2) to 8.0Nm.

8. Press the cutterhead locking lever

30

(Fig.E3) and slowly rotate the cutterhead until the

other blade can be replaced following the aboveprocedure.

OPERATION

Instructions for Use

WARNING: Always observe the safety instructions and applicableregulations.

WARNING: To reduce the risk of serious personal injury, turn tool off and

disconnect tool from power source before making any adjustments or removing/

installing attachments or accessories. An accidental start-up can causeinjury.

WARNING: Make sure there is sufficient space for the workpiece at the outfeedside.

The attention of UK users is drawn to the “woodworking machines regulations 1974” and any

subsequentamendments.

Ensure the machine is placed to satisfy your ergonomic conditions in terms of table height

and stability. The machine site shall be chosen so that the operator has a good overview and

enough free surrounding space around the machine that allows handling of the workpiece

without anyrestrictions.

The workpiece may only be inserted into the machine from the side on which the circuit

breaker is located. Note the arrow on the top of thedevice.

To reduce effects of vibration make sure the ambient temperature is not too cold, the machine

and accessories are well maintained and the workpiece size is suitable for thismachine.

Switching On and Off (Fig.F1, F2)

The On/Off switch of your DW733 is equipped with a circuit breaker. In case of motor overload,

the power supply to the motor will be cut off. If this happens, turn the machine off and press

the reset button

36

(Fig.F1).

• The workpiece should not be in contact with the cutterhead when switchingon.

To turn on, press the green start button of the switch

1

(Fig.F2). The tool now works in

continuousoperation.

• Allow the motor to reach full speed before feeding theworkpiece.

• Allow the blades to cut freely. Do notforce.

To switch off, press the red stop button of the switch

1

.

WARNING: Always turn off the tool when work is finished and beforeunplugging.

Planing (Fig.G)

WARNING:

• Remove all foreign objects. Do not plane wood with loose knots. Do not plane wood

that is severely knotted orwarped.

• Your DW733 works best with at least one flatsurface.

• For optimal results, plane both sides of your workpiece to reach the desiredthickness.

2.5

0.8

0

20 50 100 150 200

250

300

Follow the depth of cut and width guidelines shown in the table below

Width of stock (mm)

Softwood

Depth of cut (mm)

1.6

Hardwood

Loading...

Loading...