Module failed/short: With tool unplugged rotate

the bare spindle back and forth swiftly by hand

and feel for a viscous like resistance to

turning; in that the resistance increases as

speed is increased. Its best to compare this

turning resistance against a known good unit

to help understand how it should feel. If this

higher resistance is felt then either the module

or stator has shorted causing the increased

resistance.

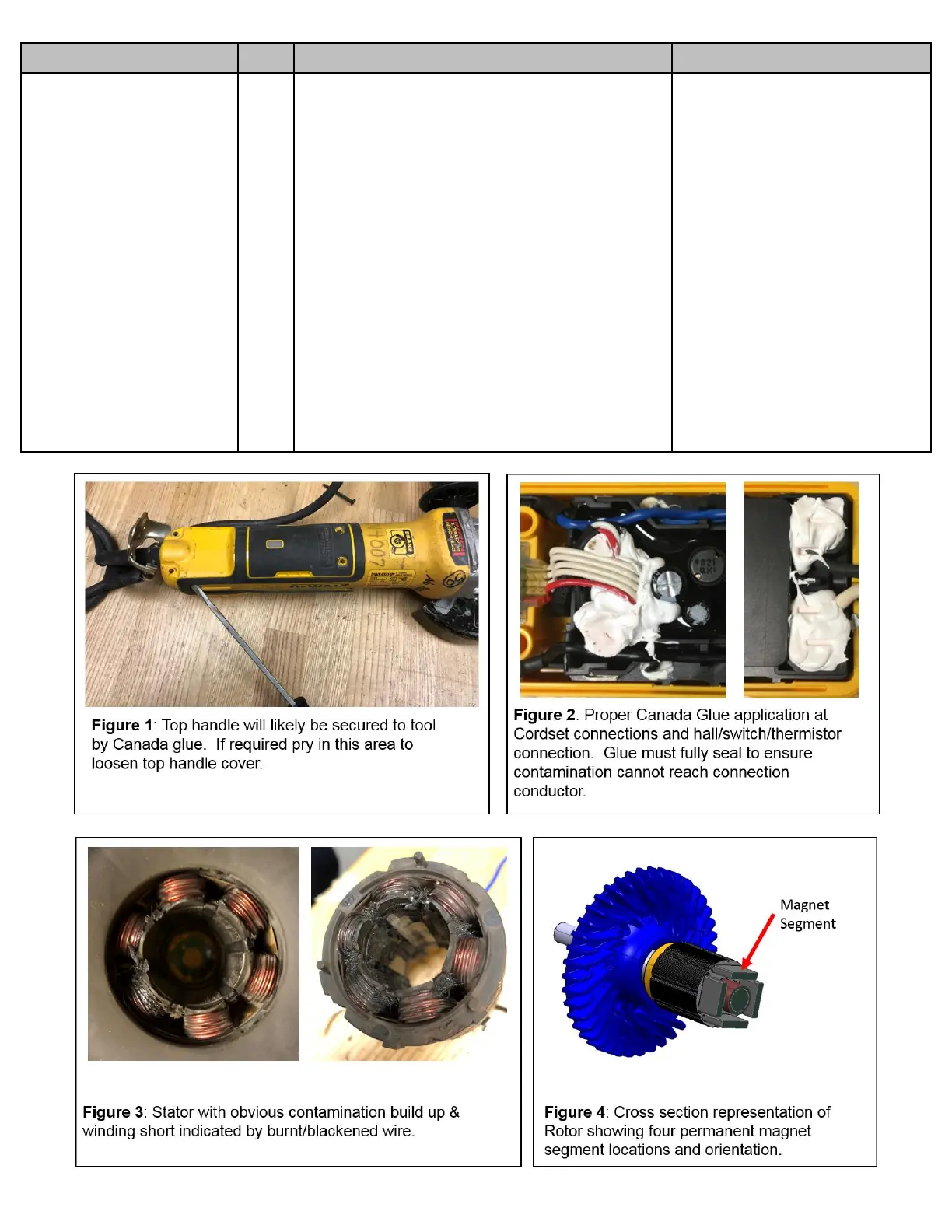

With tool unplugged remove handle covers

and shrink tube caps from the three motor-

module connections. Disconnect the three

motor-module connections while continually

checking the spindle turning resistance. If the

spindle resistance is significantly reduced

when the phases are disconnected the module

is shorted and must be replaced.

Loading...

Loading...