37

ENGLISH

Performing an Application (Fig.A)

WARNING: TO REDUCE THE RISK OF PERSONAL

INJURY, ALWAYS ensure workpiece is anchored or

clamped firmly. If drilling thin material, use a wood

“back-up” block to prevent damage to thematerial.

WARNING: Always wait until the motor has come to

a complete standstill before changing the direction

ofrotation.

1. Choose and install the appropriate chuck, adapter, and/or

bit onto the tool. Refer to Bit and BitHolder.

2. Using the mode selector dial

3

, selectthe mode

appropriate to desired application. Refer to

OperationModes.

3. Adjust the side handle

5

asnecessary.

4. Select the direction ofrotation using the forward/reverse

control button

2

. When changing the position of the

control button, be sure the trigger isreleased.

Operation Modes (Fig.A)

WARNING: Do not select the operating mode when the

tool isrunning.

Your tool is equipped with a mode selector dial

3

to selectthe

mode appropriate for the desiredoperation.

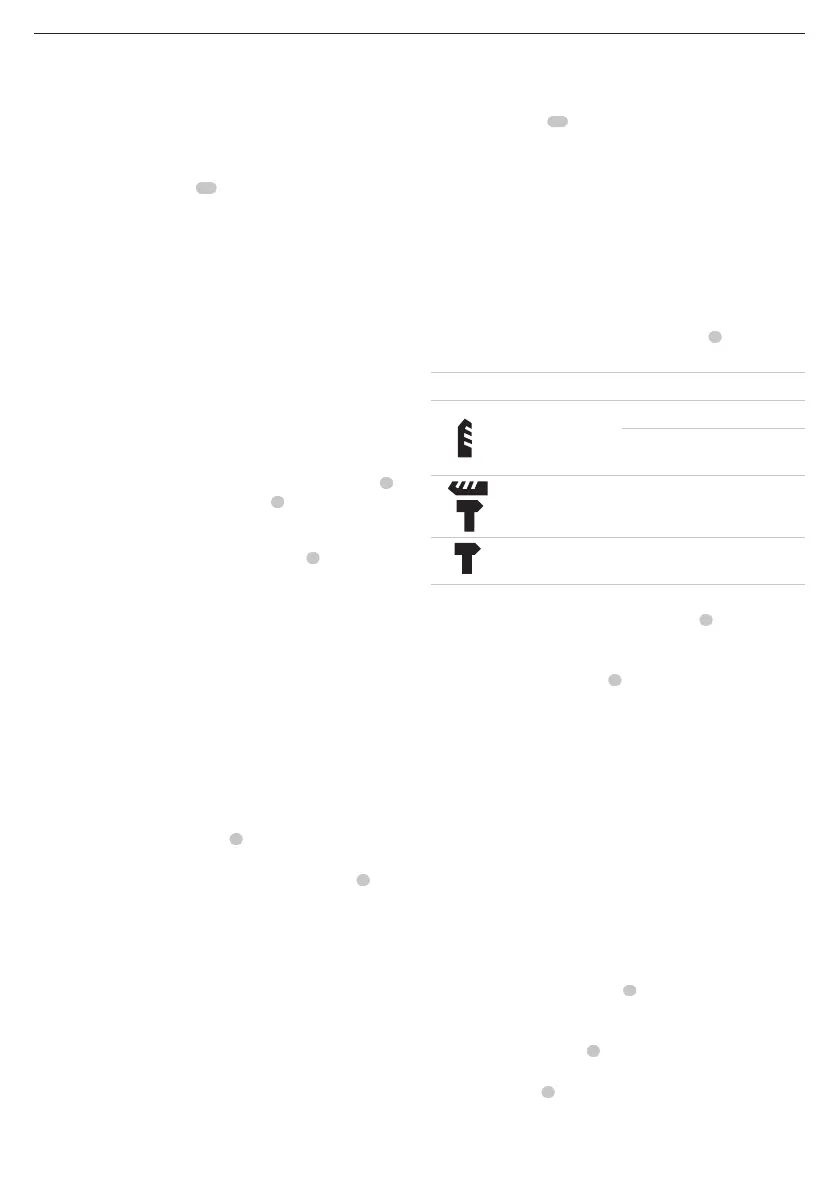

Symbol Mode Application

Rotary Drilling

Screwdriving

Drilling into steel, wood

andplastics

Rotary

Hammering

Drilling into concrete and

masonry

Hammering

only

Lightchipping

To select an operating mode:

1. Depress the mode selector release button

4

.

2. Rotate the mode selector dial so that the arrow points to the

symbol corresponding with the desiredmode.

NOTE: The mode selector dial

3

must be in rotary drilling,

rotary hammering or hammering only mode at all times. There

are no operable positions in between. It may be necessary to

briefly run the motor after having changed from 'hammering

only' to 'rotary' modes in order to align thegears.

Worklight (Fig.A)

CAUTION: Do not stare into worklight. Serious eye

injury couldresult.

There is a worklight

13

located on the front of the tool. The

worklight is activated when the trigger switch is depressed, and

will automatically turn off 20seconds after the trigger switch is

released. If the trigger switch remains depressed, the worklight

will remainon.

NOTE: The worklight is for lighting the immediate work surface

and is not intended to be used as aflashlight.

Forward/Reverse Control Button (Fig.A)

A forward/reverse control button

2

determines the direction of

bit rotation and also serves as a lock-offbutton.

To select forward rotation, release the trigger switch

1

and

depress the forward/reverse control button on the right side of

thetool.

To select reverse, depress the forward/reverse control button

on the left side of thetool.

The centre position of the control button locks the tool in

the off position. When changing the position of the control

button, be sure the trigger isreleased.

NOTE: The first time the tool is run after changing the direction

of rotation, you may hear a click on start-up. This is normal and

does not indicate aproblem.

Trigger Switch (Fig.A)

To turn the tool on, squeeze the trigger switch

3

. To turn the

tool off, release the trigger switch. Your tool is equipped with

a brake. The chuck will stop as soon as the trigger switch is

fullyreleased.

Variable Speed Trigger Switch

The variable speed trigger switch enables you to select the best

speed for a particular application. The farther you squeeze the

trigger switch, the faster the tool will operate. For maximum

tool life, use variable speed only for starting holes orfasteners.

NOTE: Continuous use in variable speed range is not

recommended. It may damage the trigger switch and should

beavoided.

Proper Hand Position (Fig.A,E)

WARNING: To reduce the risk of serious personal injury,

ALWAYS use proper hand position asshown.

WARNING: To reduce the risk of serious personal

injury, ALWAYS hold securely in anticipation of a

suddenreaction.

Proper hand position requires one hand on the side handle

5

,

with the other hand on the main handle

8

.

Active Vibration Control (AVC) System (Fig. A)

For best vibration control, hold the tool as described in Proper

Hand Position and apply just enough pressure so the damping

device on the main handle is approximately midstroke.

The active vibration control

16

neutralises rebound vibration

from the hammer mechanism. Lowering hand and arm

vibration, it allows more comfortable use for longer periods of

time and extends the life of theunit.

The hammer only needs enough pressure to engage the active

vibration control. Applying too much pressure will not make

the tool drill or chip faster and active vibration control will

notengage.

installing attachments or accessories. An accidental

start-up can causeinjury.

Loading...

Loading...