Do you have a question about the Dhollandia DH-VO.15.K1 and is the answer not in the manual?

| Brand | Dhollandia |

|---|---|

| Model | DH-VO.15.K1 |

| Category | Lifting Systems |

| Language | English |

Ramp for securing gas bottles.

Compulsory safety feature requiring two hands.

Warning about crushing and shearing hazards.

Prohibiting intoxication or distraction.

Maintaining visual control and keeping others clear.

Stowing platform and switching off power when unattended.

Stowing tail lift before moving vehicle.

Using common sense and reading the manual.

Stay clear of platform movement.

Prevent feet crushing by lowering platform.

Prevent toe/foot crushing between platform and floor.

Prevent head/limb crushing by closing platform.

Falling from height can cause serious injury or death.

Lowering onto a person causes injury or death.

Toes/feet can be crushed between platform and floor.

Feet can be crushed by lowering platform.

Crushing between platform and vehicle floor inside.

Severe crushing of feet by platform edge.

Min. 40x40cm area, 25cm from hazard zone.

Min. 40x40cm area, 25cm from hazard zone.

Min. 50cm from platform side edge.

Safe operator position for internal controls.

Auxiliary controls dependency on safety switch.

Contact agent for safety issues.

Stand on the side of the load.

Using damaged equipment poses serious risk.

Check safety systems and functions.

Contact agent for immediate repair.

Report all issues.

Covers decals, switches, battery, cables, and controls.

Do not use until serviced by technician.

Risk of falling platform impact causing injury or death.

Valid at center point, diminishes further.

Pressure relief valve protects during lifting.

Risk of injury, damage, or failure.

Best circumstances: center of gravity, mid-point.

Position close to rear, mid-point between arms.

Must be observed for safety.

Avoid load extension beyond edges.

Keep on surface near inboard edge.

Rest loads to prevent shifting.

Never drop loads onto platform.

Never drive forklifts onto platform.

Essential securing for safety.

Strongly recommended for hydraulic closure lifts.

Mind danger zones and safe operator position.

Risk of serious injury/death.

Comply with load charts and instructions.

Ensure platform lock is re-engaged.

Raise lever, manually open to 90 degrees.

Lower/lift to 15cm, then manually close.

Close until overpressure, lift for stow lock.

Turn off power and close control box.

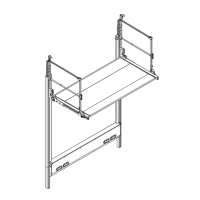

For foldable platform or retention ramps.

Lift until hydraulic system overpressure.

Step-by-step guide for opening the platform.

Lower platform 15cm to disengage stow lock.

Open until platform lands in horizontal position.

Always follow guidelines.

For loading/unloading operations.

Continue lift until hydraulic system overpressure.

Prevent shifting, falling, and injury.

Apply brakes, engage wheels.

Read manual, wear protective gear.

Observe capacity and load charts.

Keep area clear of obstacles and people.

Maintain constant visual control.

Be aware of potential pinch points.

Ensure visibility via lights, flags, cones.

Load placement and operator stance.

Keep feet clear of platform edge.

Stand clear of platform area and pinch points.

Crushing, falling hazards, load stability, footing.

Immediate stop of liftgate.

Loading...

Loading...