Do you have a question about the Dhollandia DH-VOU 16 K2K9 and is the answer not in the manual?

| Brand | Dhollandia |

|---|---|

| Model | DH-VOU 16 K2K9 |

| Category | Lifting Systems |

| Language | English |

Important legal notices and limitations of liability for DHOLLANDIA.

Specific terminology for the DH-VOU K2K9 liftgate model.

Defines installation dimensions and measurement parameters for liftgate fitting.

Initial steps and considerations before beginning the liftgate installation.

Specifies key dimensions required for liftgate mounting and fitment.

Information on where to find additional installation resources and support.

General installation advice, including risk assessment and compliance.

Specific safety and functional guidelines for liftgates operating above vehicle floor.

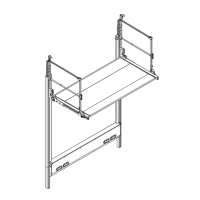

Requirements and considerations for fitting guard rails to prevent falls.

Guidelines on installing audible and visible alarms for safety.

Safe procedures for handling and lifting the lift frame components.

Detailed steps and precautions for welding the liftgate components.

Procedures for installing the liftgate using bolted connections.

Guidance on marking and drilling holes for bolt-on installation.

Steps for securing the lift frame using bolts and ensuring proper alignment.

Instructions for mounting the power pack unit onto the vehicle chassis.

Procedures for trimming lift columns to ensure proper ground clearance.

Detailed guide for installing the primary toggle control switch.

Instructions for installing the cabin-mounted control switch.

Guide for installing an optional 2-button remote control system.

Procedures for connecting the main battery and ground cables to the liftgate.

Provides the general hydraulic and electric schematic for the liftgate.

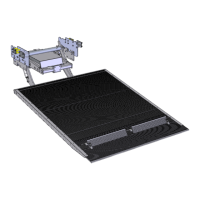

Steps to adjust the platform pitch for level ground alignment.

How to adjust the platform lock mechanism for opening and closing.

Guidance on adjusting or servicing the platform fold/unfold assist mechanism.

Adjusting the upper end stops for proper platform parallelism.

A checklist for performing the final quality inspection before delivery.

Proper placement and use of the 'out of service' warning decal.

Detailed explanation of various safety, mandatory action, and prohibition signs.

Table of specified torque values for different bolt types and classes.

Recommended cable sizes and battery/generator requirements for the system.

Guidelines for safe operator positioning to avoid hazards on the platform.

Final closing remarks and contact information for additional support.

References for obtaining general hydraulic and electric wiring diagrams.

Checklist for performing routine maintenance and repair tasks.

Loading...

Loading...