20

PM-000005 - Trencher Operators Manual - December 2012

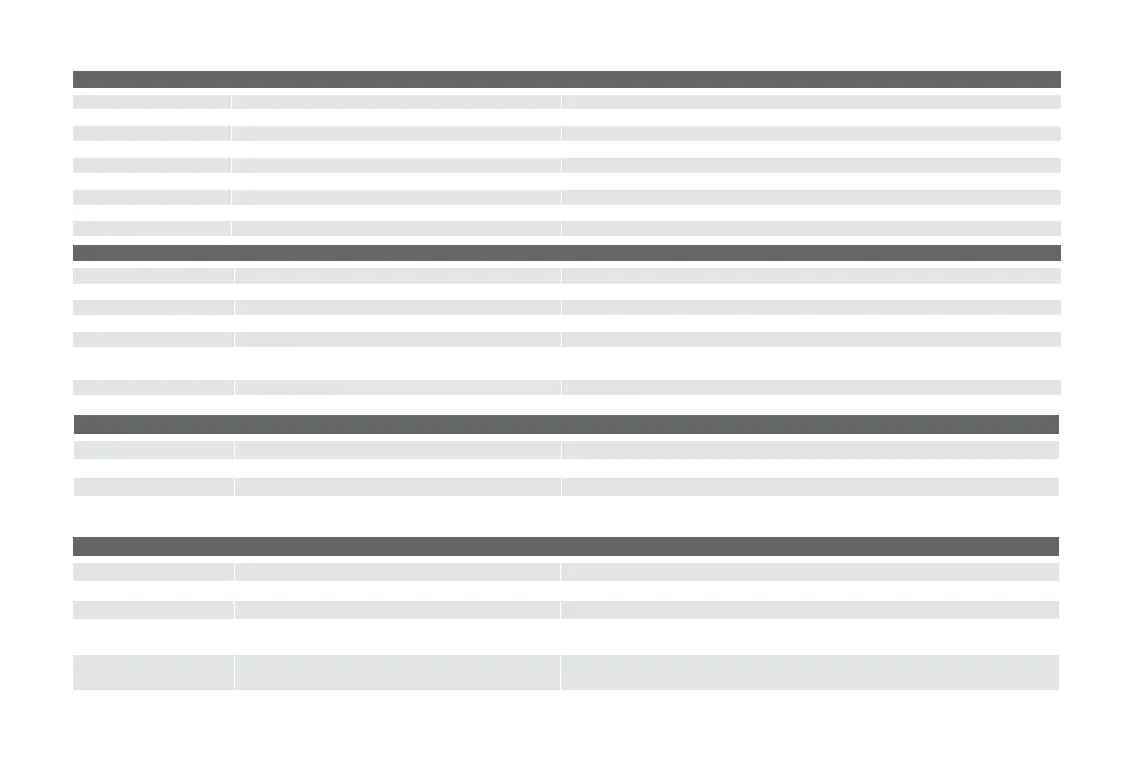

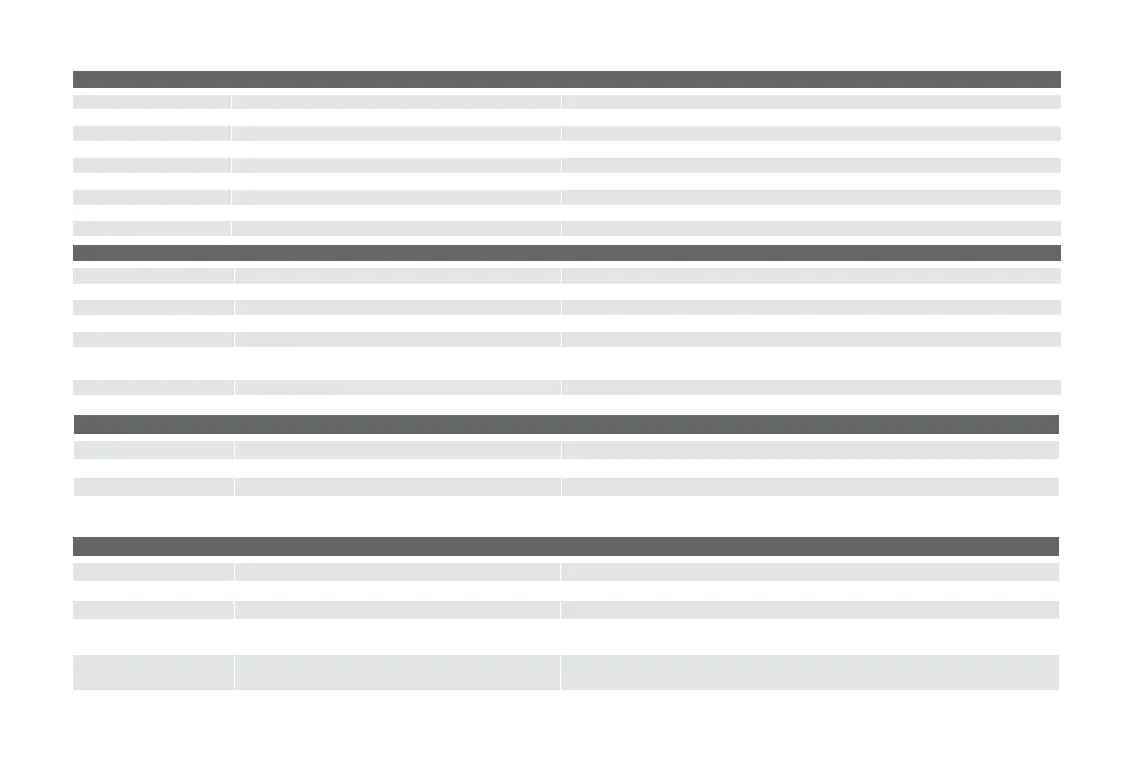

8 TroubleshooTinG

CHAIN

TROUBLE POSSIBLE CAUSE REMEDY

Chain does not turn Quick Coupler not completely engaged Check and complete engagement

Quick Coupler failure Replace faulty coupler

An obstruction in one of the hose Remove obstruction

Hydraulic Motor failure Repair or replace. Contact DIGGA dealer

Chain drive failure Check & repair. Contact DIGGA dealer

Nose roller bearing failed Replace bearing

Digging chain too tight Loosen chain tension

Sand or spoil material build up in tooth root of sprocket Raise out of ditch, reverse chain & run to clear build up OR Loosen chain tension

DIGGING

TROUBLE POSSIBLE CAUSE REMEDY

Does not dig fast enough Worn Teeth Replace teeth if necessary

Relief valve set below specications Test and reset if necessary

Quick coupler or Hose restriction Inspect and repair as needed

Hydraulic system too hot Shut down and cool

Cutting a ditch size beyond the machine capabilities REMEMBER: Your Trencher only has the horsepower transmitted through the Hydraulic

Hoses, NOT the full horsepower of the engine

Auger/s running on the ground Raise Trencher - Keep Auger/s off ground

Chain too tight Adjust to Proper Tension

BOOM, DANGER BAR, FOLDBACK CRUMBER BAR

TROUBLE POSSIBLE CAUSE REMEDY

Trenching Boom bent Abuse Replace

Danger Bar bent Abuse Replace

Fold back CRUMBER

BAR bent

Abuse Replace

HYDRAULIC OIL

TROUBLE POSSIBLE CAUSE REMEDY

Hydraulic oil overheating Relief valve set too low on Parent Machine. Test & set as needed.

Restriction in Quick Release Coupler or hose. Inspect and repair as needed

Hydraulic Motor or hoses not size balanced to

Parent Machine

Check ows and recommendations and change if necessary. (see DIGGA Dealer)

Parent Machine not equipped with oil cooler or sufcient

sump capacity

Stop and allow to cool naturally when it gets hot.

Loading...

Loading...