92

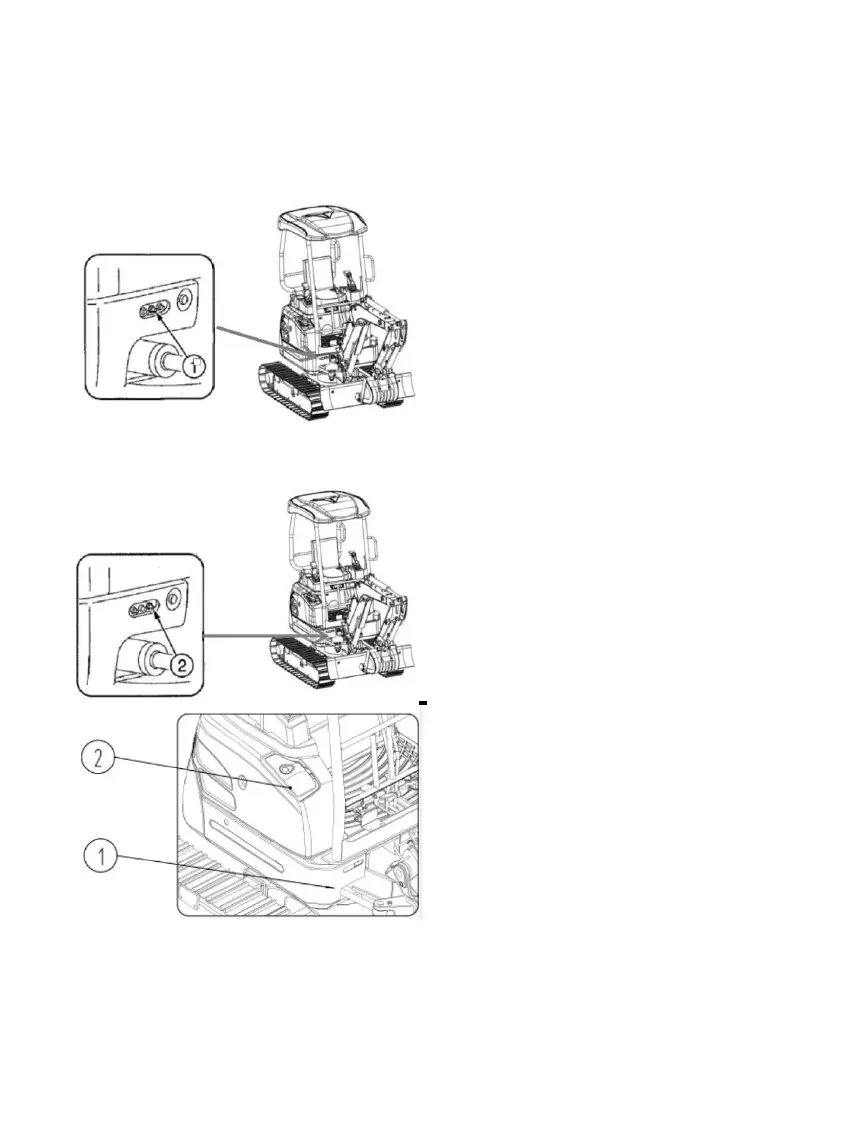

Lubricate the slewing bearing

Do not slew during lubrication. Otherwise, you may be entangled into the machine.

Take out the cover plate (1).

Use a grease gun to inject lubricating grease via the grease fitting (3) of grease

Stop the machine as per the posture shown in

above diagram and stop the engine.

Lubricate the grease fitting (1) by a grease gun.

Start the engine, lift the bucket, and rotate

clockwise for 90°.

Lower the bucket onto the ground and then

stop the engine.

Repeat above steps 2~4 for 3 times.

Wipe away the grease drained from the

slewing bearing and grease pipe.

Lubrication of slewing motor gear

Lubricate the grease fitting (2) by a grease gun.

Wipe away excessive grease.

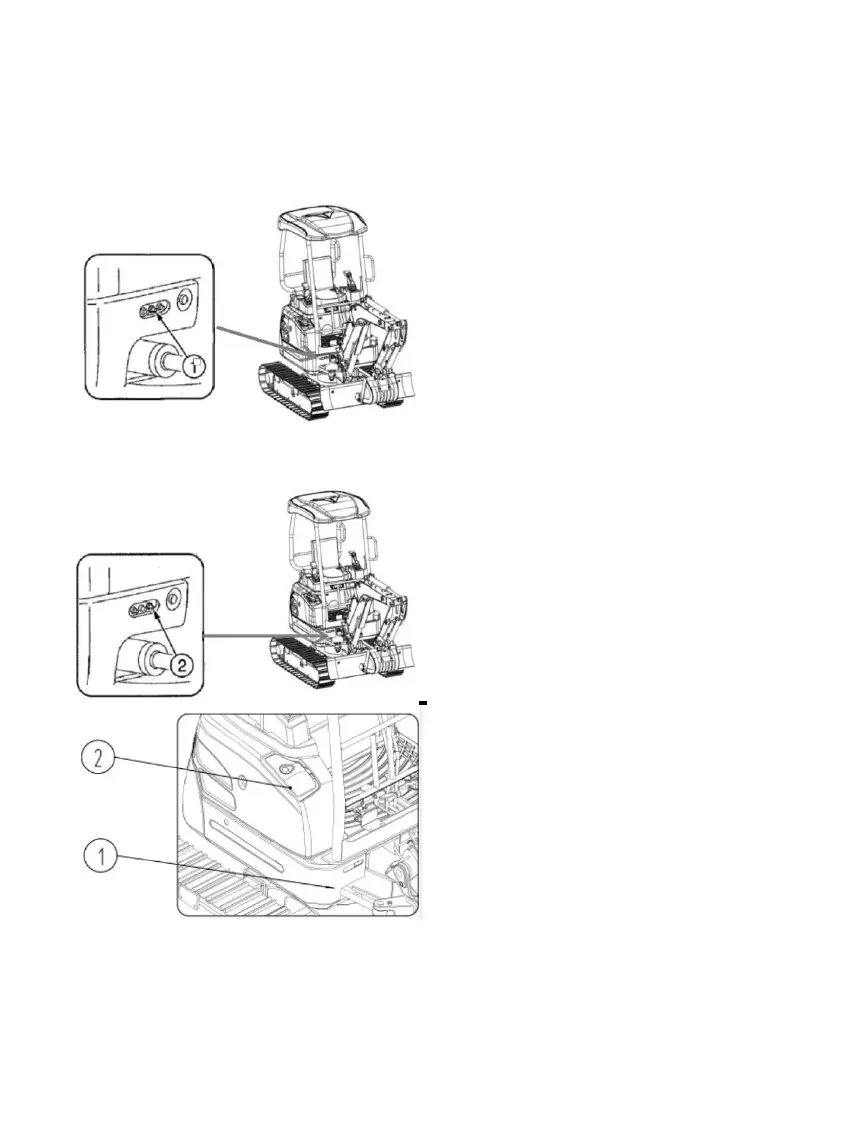

Water drainage from fuel tank

Tighten the fuel tank cap securely.

Use correct fuel grade based on the season.

Take out the fuel tank cap (2).

Place a box beneath the water drainage plug

(1).

Loosen the water drainage plug (1) to fully

drain the water and the deposits from the

tank.

Tighten the water drainage plug (1).

Tighten and lock the fuel tank cap (2).

Bleed the air.

Air Bleeding of Fuel System

Note: The air content in the fuel system will cause start failure or start difficulty of engine. Bleed

the air by same procedure described above when the fuel tank is empty.

Loading...

Loading...