DK-1100A Ink Roll Coder Operation Manual

3. INSTALLATION AND RELOCATION

3.1 Installation

3.1.1 Installation Requirements

3.1.2 Checking Home Position of the Type Holder

Packaging machine runs well

Stable power supply AC220V 10V, max. 2A fuse

Reliable printing signal can be from relay, proximity sensor or PLC

Enough space for installing printer

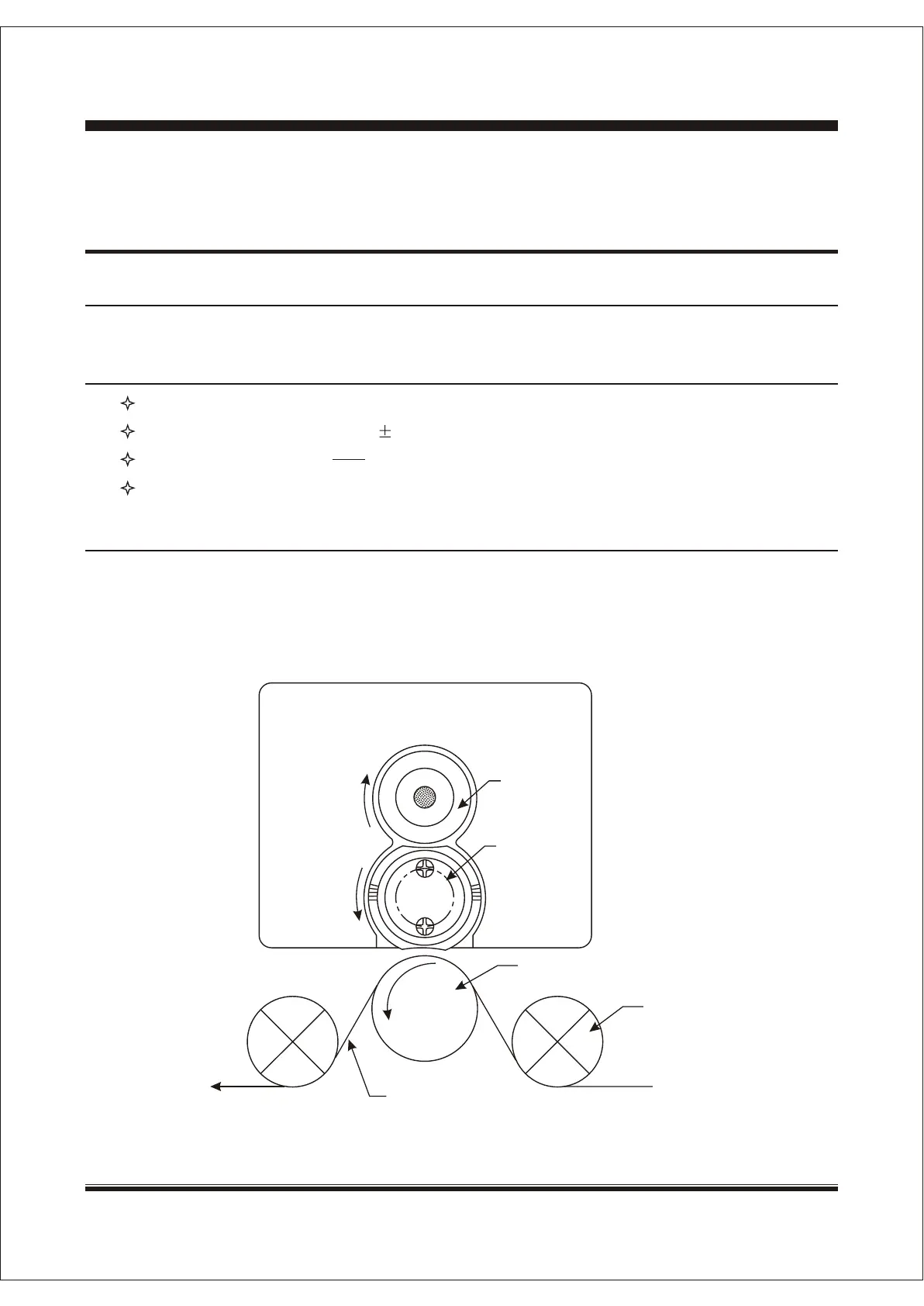

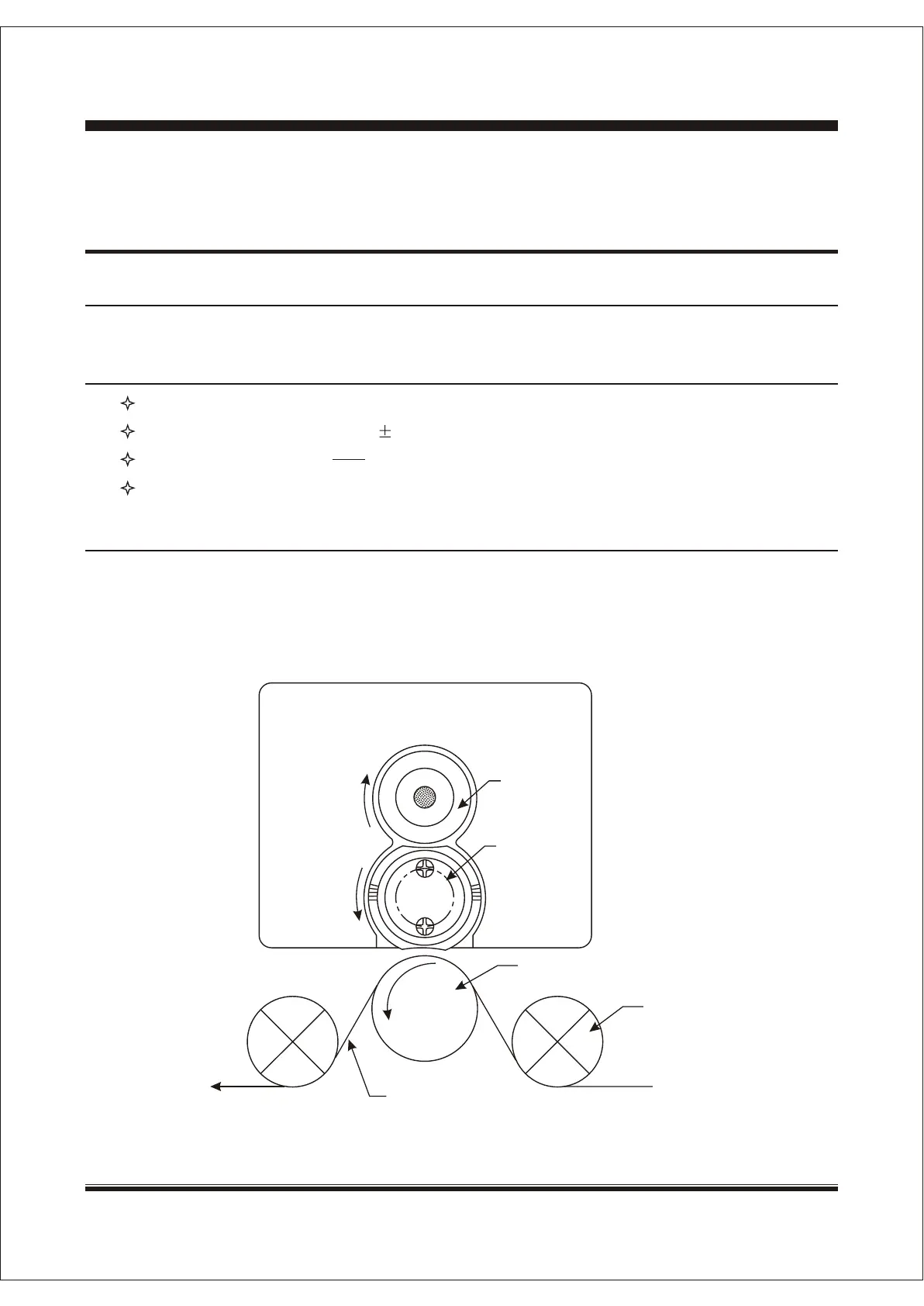

At the very beginning of the installation, manually check the home position, that is the Hot Ink Roll,

Rubber Roller and Pressure Roller should be in position as diagram 4. The rubber wheel can not

touch pressure roller or packing film. Otherwise, it will cause failed or missed printing.

Diagram 4

Hot Ink Roll

Rubber Wheel

Hot Ink Roll

Rubber Wheel

Pressure RollerPressure Roller

RollerRoller

Packaging FilmPackaging Film

SHANGHAI DIKAI SEPARATE MACHINERY CO., LTD.SHANGHAI DIKAI SEPARATE MACHINERY CO., LTD. 3-123-12

Loading...

Loading...