•Allow adequate access for servicing pump and

piping.

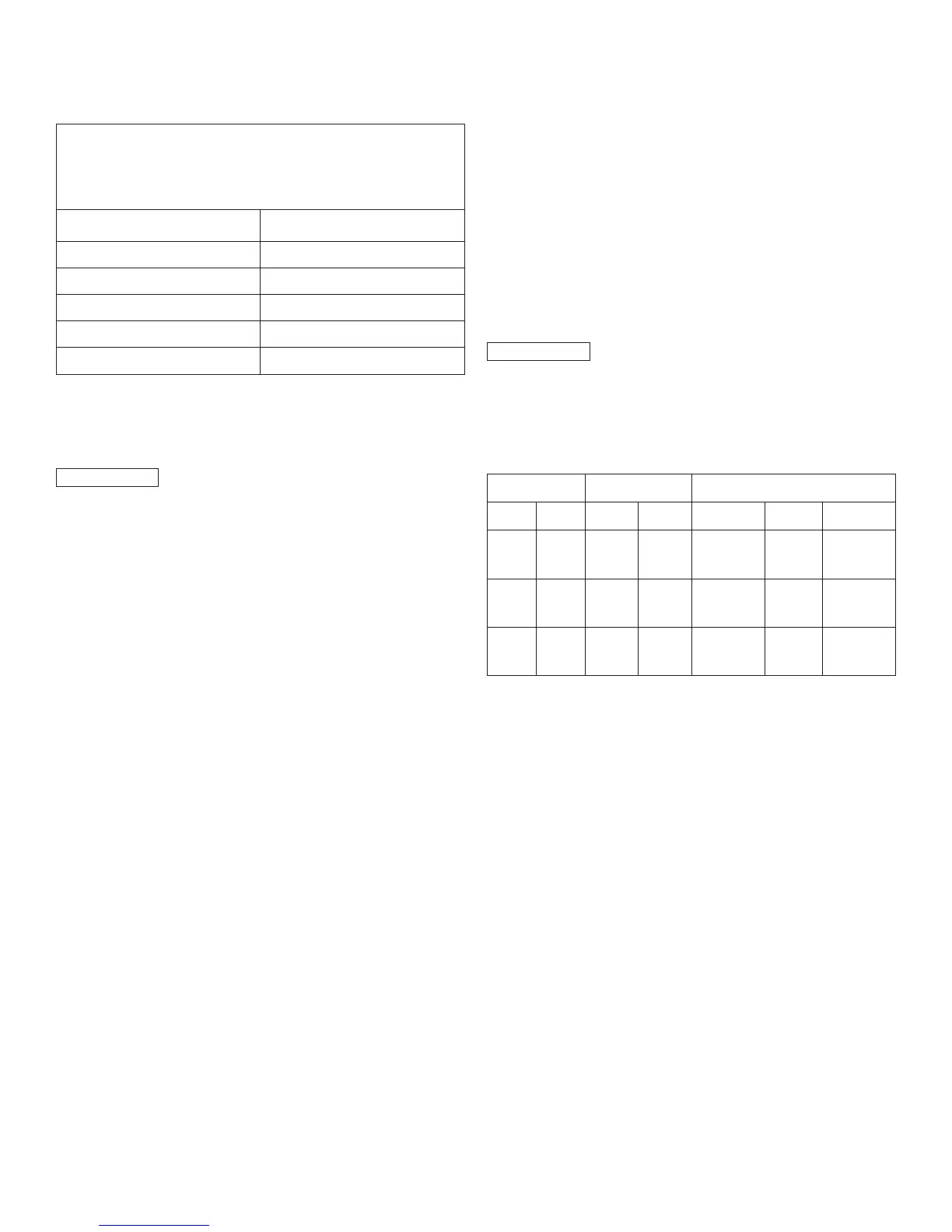

Pipe Sizing Chart

NOTE: It is recommended that a minimum length

of piping, equivalent to 10 pipe diameters, be used

betweenthepumpsuctioninletandanyplumbingttings.

▲WARNING Hazardous Pressure.

Pumps,lters,andotherequipment/components

ofaswimmingpoolltrationsystemoperateunder

pressure. Incorrectly installed and/or improperly

testedltrationequipmentand/orcomponentsmay

fail resulting in injury and/or property damage.

2. Plumbing: Use Teon tape to seal threaded

connections on molded plastic components. All

plasticttingsmustbeneworthoroughlycleaned

before use. NOTE: Do NOT use Plumber’s

Pipe Dope as it may cause cracking of the plastic

components.WhenapplyingTeontapetoplastic

threads, wrap the entire threaded portion of the

malettingwithonetotwolayersoftape.Windthe

tape clockwise as you face the open end of the

tting,beginningattheendofthetting.Thepump

suction and outlet ports have molded-in thread

stops. Do NOT attempt to force hose connector

tting past this stop. It is only necessary to tighten

ttingsenoughtopreventleakage.Tightenttingby

hand and then use a tool to engage tting an

additional1-1/2turns.UsecarewhenusingTeon

tape as friction is reduced considerably. Do NOT

over-tighten tting or you may cause damage. If

leaksoccur,removeconnector,cleanoffoldTeon

tape, re-wrap with one to two additional layers of

Teontape,andre-installconnector.

3. Fittings:Fittingsrestrictow.Forbetterefciency,

use the fewest possible ttings (but at least two

suctionoutlets).Avoidttingsthatcouldcausean

airtrap.PoolandspattingsMUSTconformtothe

International Association of Plumbing and

Mechanical Ofcials (IAPMO) standards. Use a

non-entrapping suction tting in pool (multiple

drains) or double suction (skimmer and main drain).

CHAPTER 3: ELECTRICAL

1. Ground and bond motor before connecting to

electrical power supply. Failure to ground and bond

pump motor can cause serious or fatal electrical

shock hazard.

2. Do NOT ground to a gas supply line.

3. To avoid dangerous or fatal electrical shock, turn

OFF power to motor before working on electrical

connections.

4. Ground Fault Circuit Interrupter (GFCI) tripping

indicates electrical problem. If GFCI trips and won’t

reset, consult electrician to inspect and repair

electrical system.

▲WARNING Fire Hazard.

5. Match supply voltage to motor nameplate voltage.

Insure that the electrical supply available agrees

with the motor’s voltage, phase, and cycle, and

that the wire size is adequate for the H.P. (KW)

rating and distance from the power source.

NOTE: All electrical wiring MUST be performed

by a licensed electrician, and MUST conform

to local codes and NEC regulations. Use copper

conductors only.

6. Voltage: Voltage at motor MUST NOT be more

than 10% above or below motor name plate rated

voltage, or motor may overheat, causing overload

tripping and reduced component life. If voltage is

less than 90% or more than 110% of rated voltage

when motor is running at full load, consult Power

Company.

7. Grounding and Bonding: Install, ground, bond,

and wire motor in accordance with local or national

electricalcoderequirements.Permanentlyground

motor. Use green ground terminal provided under

motor canopy or access place; use size and type

wire required by code. Connect motor ground

terminal to electrical service ground. Bond motor

to pool structure. Bonding will connect all metal

parts within and around the pool with a continuous

wire. Bonding reduces the risk of a current passing

between bonded metal objects, which could

potentially cause electrical shock if grounded

6950 51st Street Kenosha WI 53144|Orders and Customer Care: 1-800-574-7665|Fax: 1-800-323-5932|Doheny.com

MAXIMUM RECOMMENDED SYSTEM FLOW

Pipe Size Flow Rate GPM

[mm] [Liter/Min]

1 in. [32 mm] 20 GPM [75]

1-1/4 in. [40 mm] 30 GPM [110]

1-1/2 in. [50 mm] 45 GPM [170]

2 in. [63 mm] 80 GPM [300]

2-1/2 in. [75 mm] 110 GPM [415]

3 in. [90 mm] 160 GPM [600]

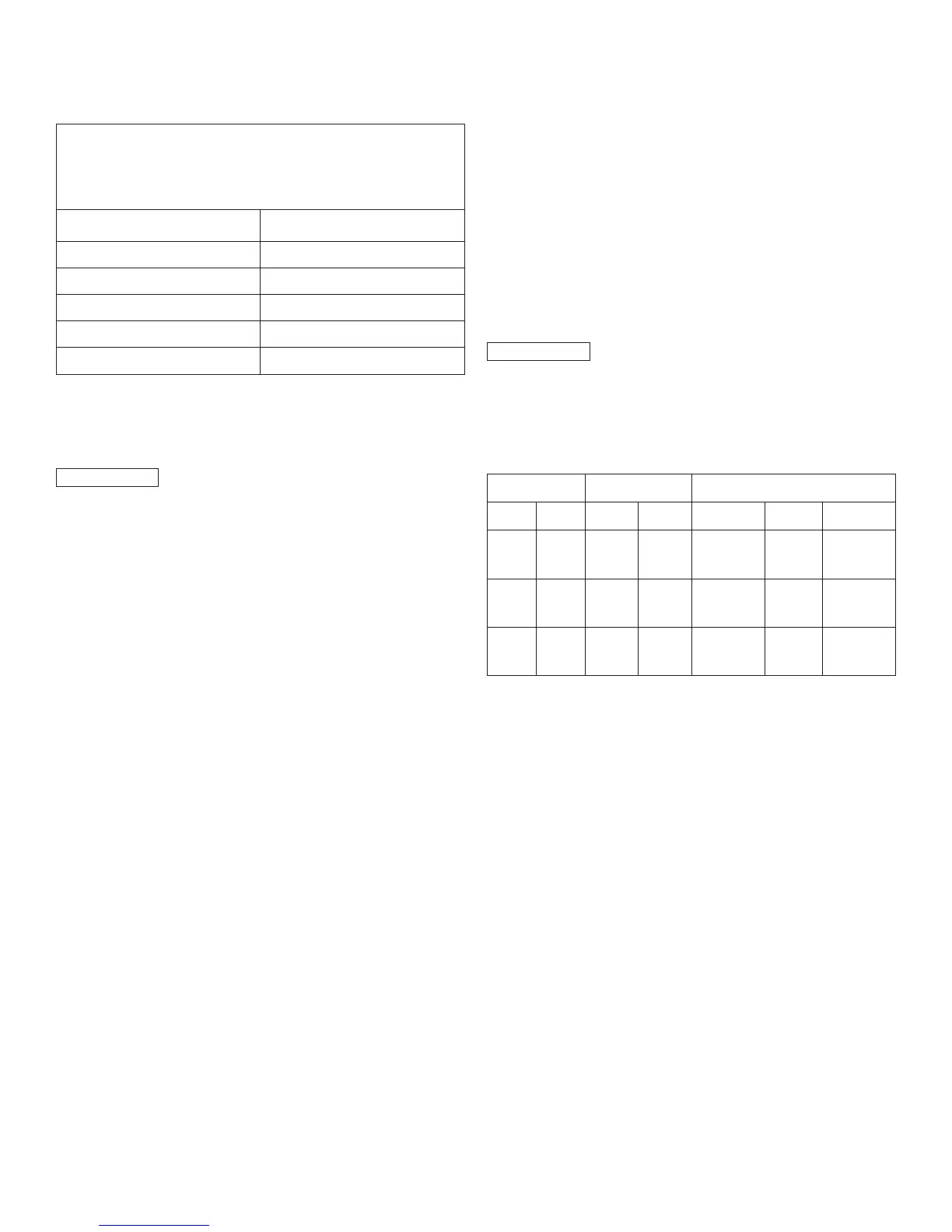

MAX RATE FULL RATE 60 HZ 1PH

HP KW HP KW Voltage Amps Wire

- - 1/2 0.37 208-230 10A 14 AWG

115 15A 14 AWG

1 0.75 3/4 0.55 208-230 10A 14 AWG

115 15A 14 AWG

1-1/2 1.10 1 0.75 208-230 15A 14 AWG

115 20A 12 AWG

Loading...

Loading...