6

3. Lower the lateral arm assembly until the shoul-

der’s keys engage the shoulder base’s grooves

at positions (1) and (3). See FIG. 12.

PINCH POINT HAZARD. Keep clear of pivot

area when raising or lowering lateral arm

assembly. Failure to obey this caution could

result in injury.

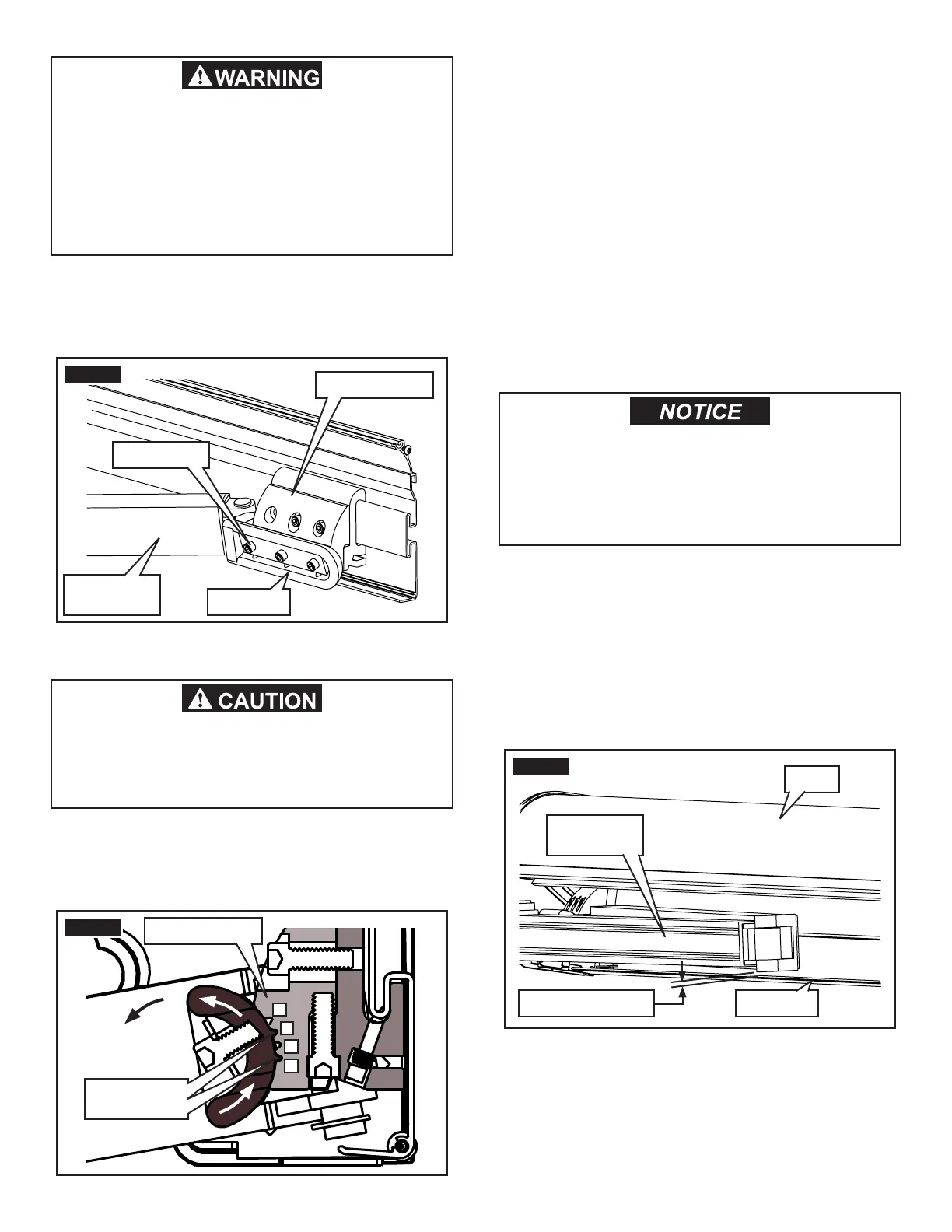

2. Loosen the (3) cap screws (3.5 turns maximum)

clamping the shoulder to the shoulder base on (1)

lateral arm assembly only. See FIG. 11.

IMPACT OR CRUSH HAZARD. Make sure lat-

eral arm assemblies are taped and supported

securely with lead rail before loosening fas-

teners. Otherwise, the lead rail and lateral arm

assemblies could shift or drop quickly and

unexpectedly. Failure to obey this warning

could result in death or serious injury.

FIG. 12

4

3

2

1

Shoulder’s

Keys

Shoulder Base

FIG. 11

Shoulder Base

Shoulder

Lateral Arm

Assembly

Cap Screws

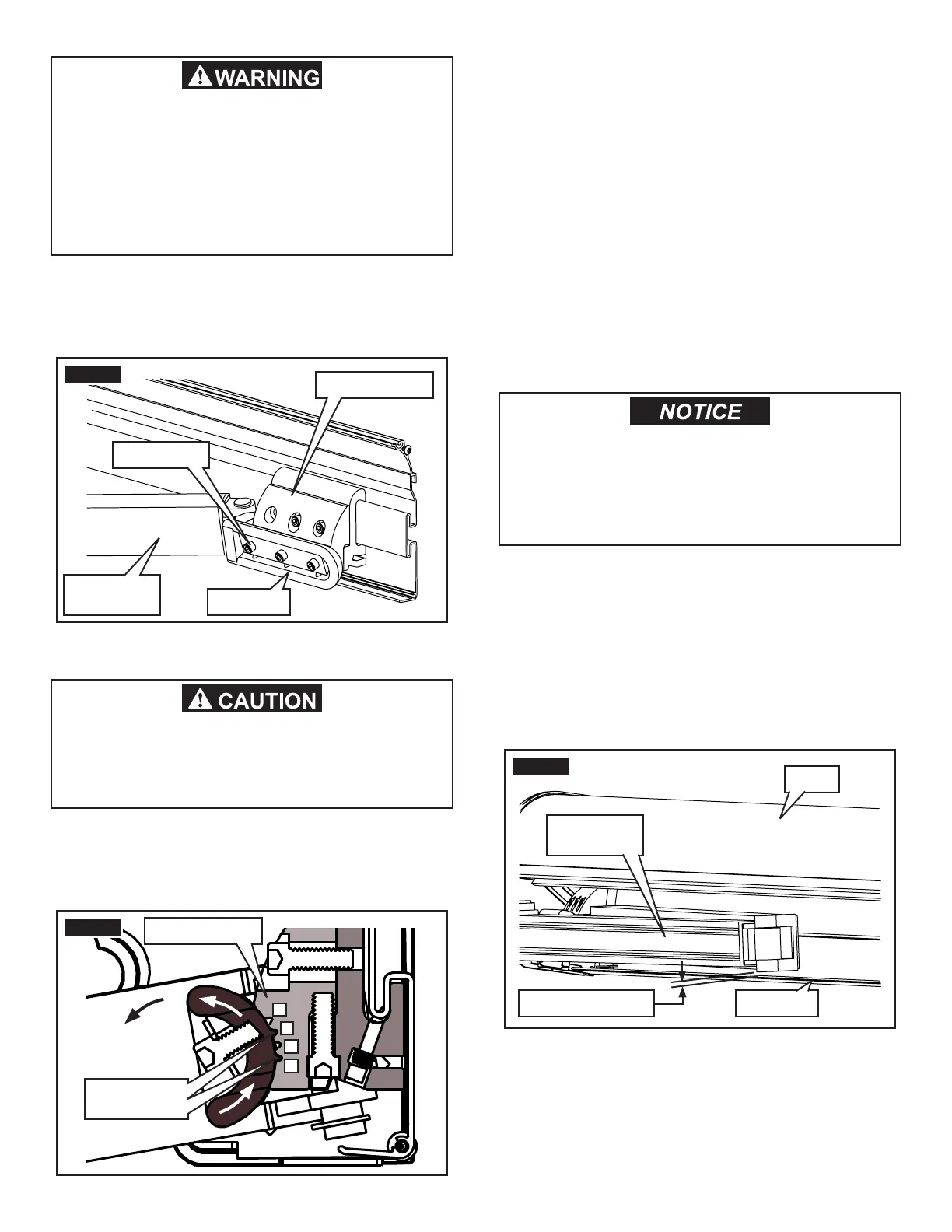

C. Readjust Lateral Arm Assemblies (If

Required)

After fabric slope adjustment, verify that cassette awning

will close without interference. If awning will not close

properly, or if lateral arm assembly’s elbow will not clear

back rail, it will need readjustment. See FIG. 13.

Note: The lateral arm assembly’s elbow should just clear

(slightly above) lower lip of back rail without rubbing. Ad-

justing too high may interfere with top, or cause rubbing

on awning fabric.

4. Tighten cap screws to 140 in-lb torque to re-clamp

the shoulder to the shoulder base. See FIG. 11.

5. Repeat steps (2) through (4) for each lateral arm

assembly. Remove tape when done.

FIG. 13

Elbow Clearance

Lateral Arm

Assembly

Top

Back Rail

Do not allow lateral arm assemblies to rub

against lower lip of back rail when closing,

or against awning fabric when in fully opened

position. Failure to obey this notice could

result in property damage.

Loading...

Loading...