8

EN

Installation Magnetic-Drive Centrifugal Pump

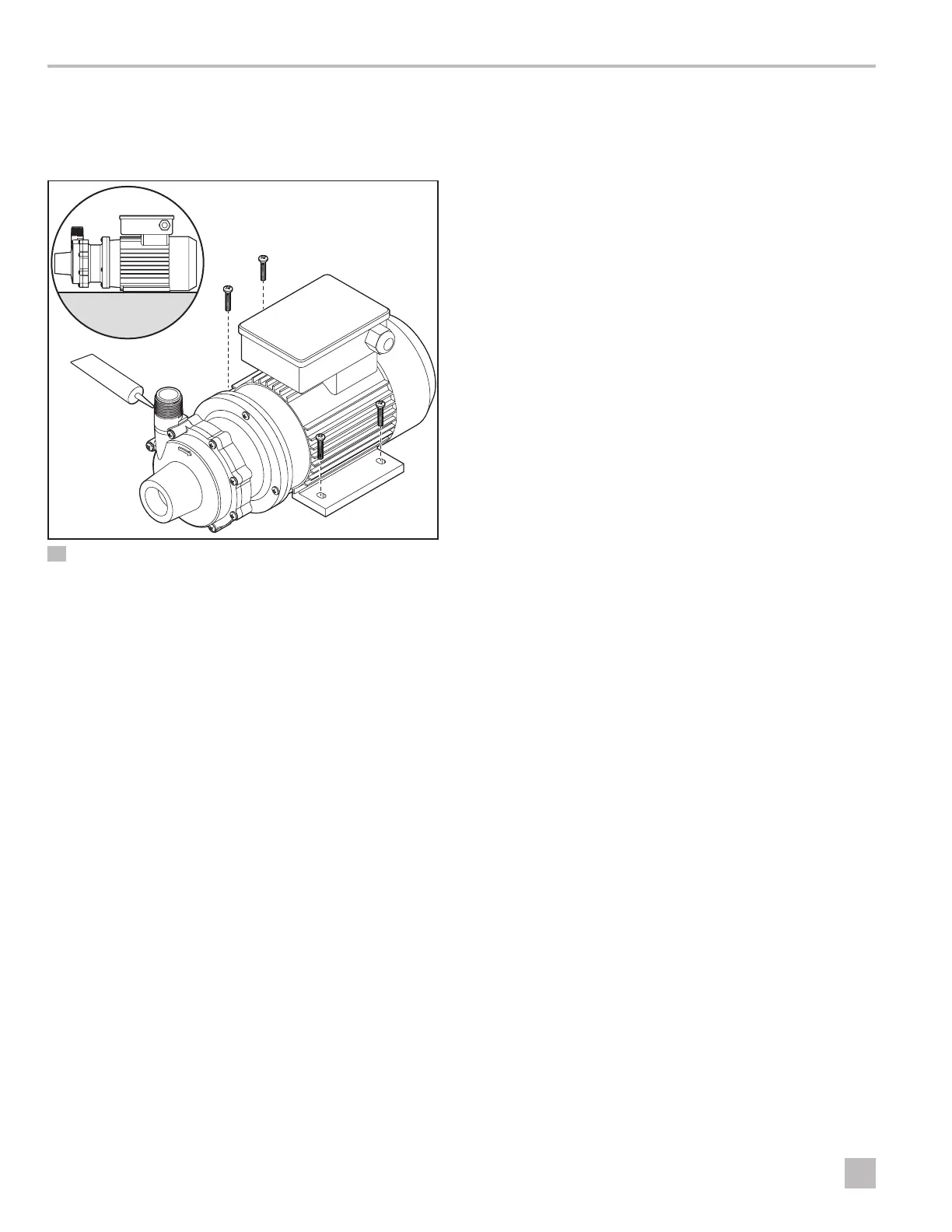

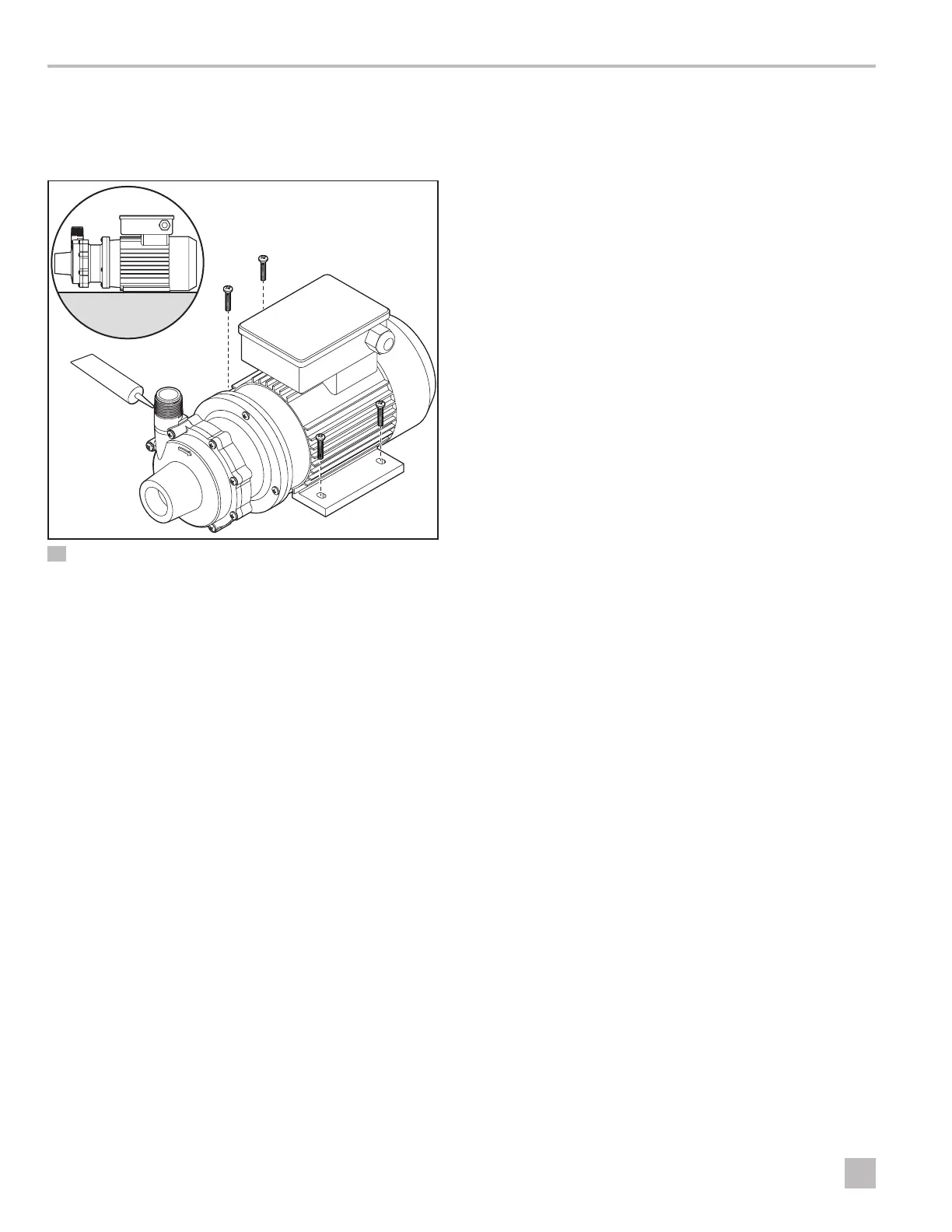

5.3 Mounting the Pump

Use the following instructions to securely mount the

pump in the desired location.

q

e

w

r

4 Mounting With Vertical Discharge Orientation (P030 Shown)

q

Sealant

e

Foot

w

Motor

r

Pump Head

1. Place the pump motor in the desired location and

mark the position of the mounting holes.

2. Drill holes for the mounting screws.

3. If the pump was packaged with plastic shipping

shims, place the shims under the motor feet.

4. Tighten the screws to secure the pump into position.

5. Use an appropriate pipe sealant or tape on the

threads and other piping connections.

6. Tighten all connections, using appropriate tools for

the selected piping materials.

5.4 Connecting the Piping

Use the following guidelines for connecting the piping.

• Place the piping with independent support near the

pump to eliminate any strain on the pump casing.

• A strainer on the inlet pipe should be used to remove

debris before the liquid enters the pump.

• Position the piping on the suction side of the pump

in a straight and short configuration to minimize pipe

friction.

• Keep bends and valves at least ten pipe diameters

away from the suction and discharge.

• Install the suction piping to be level or sloping slightly

upward toward the pump. To prevent air pockets, the

suction line should not have any high spots.

• The suction line should be at least as large as the

suction inlet port or one pipe size larger so that it

does not affect the NPSHa. Do not reduce the suction

line size.

• A check valve and control valve (if used) should be

installed on the discharge line. The check valve helps

prevent the pump from water hammer damage. This

is particularly important when the static discharge

head is high. The control valve is used for regulating

flow.

• Isolation valves on the suction and discharge lines

can be used to make the pump accessible for

maintenance.

• If flexible hose is preferred, use a reinforced hose

rated for the proper temperature, pressure and

chemical resistance against the fluid being pumped.

• Use an appropriate pipe sealant or tape on the

threads and other piping connections.

• The suction valve must be completely open to avoid

restricting the suction flow.

• A flush system in the piping can be installed to allow

the pump to be flushed before it is removed from

service.

I

P048, P075, P100, P137, P150, and P200 pump

models are provided with a provision for a

customer-installed 1/4 in. (6 mm) drain in the

impeller housing. For the best performance, ensure

the pump piping is sized appropriately for the flow

rate.

Loading...

Loading...