19

Donaldson Company, Inc.

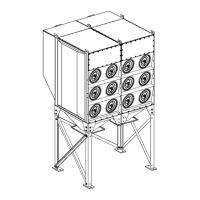

Filter Removal

1. Turn off power to the collector.

2. Begin filter replacement at one of the top filter

access ports. Continue by replacing the remaining

filters in the top row. Proceed to replace filters in the

next rows.

Replacing filters row by row starting at the top will

help limit dusting during replacement.

3. Remove access cover by turning knob

counterclockwise.

Do not use the access cover

features as climbing equipment.

Use safe practices for maintenance and

installation.

Do not drop filters

4. Break the seal between the filter cartridge and the

sealing surface.

5. Slide each filter out the access port along the

suspension yoke and dispose of properly.

6. Inspect and clean the sealing surface if necessary.

Clean dust from gasket sealing

area to ensure a positive filter

gasket seal.

7. Clean any dust from the yoke threads that may have

accumulated during the filter removal.

8. Check for any accumulation of dust in the storage

area and remove as necessary.

Compressed Air Components

1. Periodically check the compressed air components

and replace damaged or worn components as

necessary.

2. Drain moisture following the manufacturer’s

instructions.

3. With the compressed-air supply ON, check the

cleaning valves, solenoid valves, and tubing for

leaks. Repair or replace as necessary.

Dust Disposal

To avoid possible damage to

the fan motor, maintain a seal

below the collector if servicing the dust storage

device while the fan is running.

1. Empty dust container(s) (drum or bin) as necessary to

minimize dust in the hopper.

2. If the optional 55-gallon drum attachment is used,

empty when dust container is 2/3 full.

3. If optional slide gate is used, close gate before

servicing dust container.

Sharp edge of slide gate may

result in personal injury while

closing the slide gate. Keep hands clear when

operating the slide gate.

4. Check integrity of gasket under drum cover.

5. Replace or reinstall dust container and open gate (if

applicable).

Filter Installation

1. Slide the gasket end of each new filter onto the end

of the suspension yoke.

The filter shape and yoke work

together to ensure proper filter

alignment during filter installation. To assist

with alignment, an alignment mark (r) at the

top of the filter endcap (non-gasketed end)

must match with the alignment mark (s) at the

top of the filter access opening.

2. Inspect cover gaskets. Clean and/or replace as

necessary.

3. After new filters have been installed, place the

access cover on the yoke and and hold it in position

while tightening the knob securely by hand (3 turns)

before using tool assist option.

The access cover must be

properly aligned to ensure a dust

tight seal to the housing.

Do not exceed 150 in-lbs (12.5 ft-lbs) torque

when securing the access cover as over

tightening may cause damage to the filter and/

or equipment.

When filter installation is complete, check to

ensure that each access cover is seated and

sealed against the filter housing to ensure a

dust tight housing seal.

Loading...

Loading...