© 2023 No reproduction in whole or in part without prior written approval. 55101_Instructions

55101: CHOKE CONVERSION KIT PAGE 2 OF 9

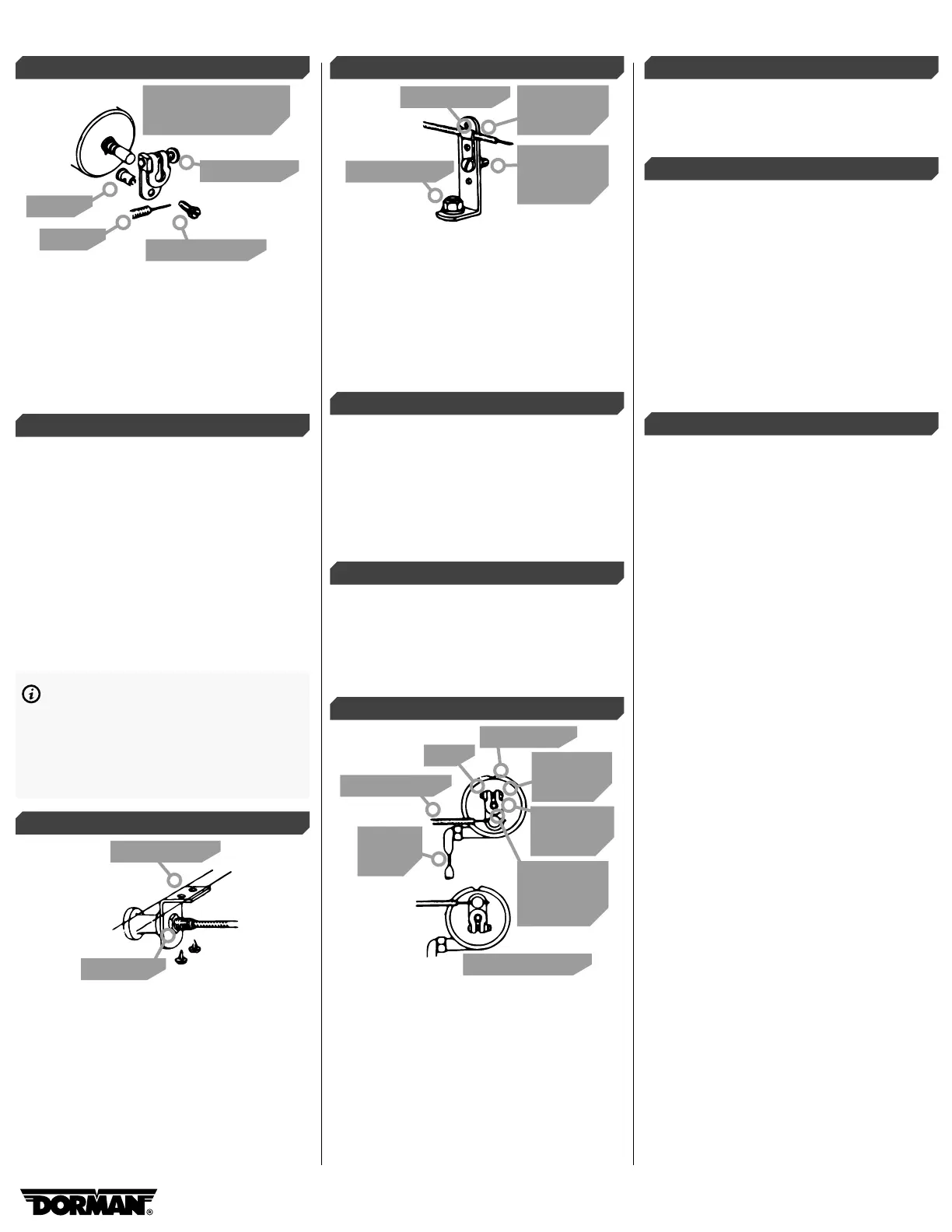

STEP 4:

Collar

Cable

Long screw

Machine screw

Mount on activator

shaft outside cap

Mount the swivel assembly on the shaft on the

outside of the cap. This requires two operations.

First, assemble long screw and nut as shown, but

do not tighten. Second, insert the small machine

screw at the bottom of the assembly and screw

into the collar. Do not tighten because the choke

control wire will have to be inserted in the collar.

STEP 5:

Place the cap as assembled on the carburetor,

making sure the U-shaped opening in the

activator lever catches the choke tang. Using the

same screws and clip which held the automatic

choke in place, fasten the new choke cap and

conversion mechanism on the carburetor. Move

the buttery on top of the carburetor back and

forth, making certain the activator shaft and

swivel assembly are also moving. If they are not,

the choke tang is not engaged in the U-shaped

opening on the activator lever or the shaft is not

set deep enough to catch the tang. Adjust as

necessary and proceed.

NOTE: Some carburetors have a double

choke tang. If the tangs are metal, use

pliers to bend one of the prongs down 90°.

If they are nylon, use cutters to remove

one of the prongs. Next, install so that the

lever catches the remaining tang.

STEP 6:

Dash bracket

Lock nut

Locate a convenient position on the underside

of the instrument panel (dash) for mounting the

dash bracket. Use the bracket as a template to

drill two 1/16” diameter holes and the mount

bracket with two supplied sheet metal screws.

STEP 7:

Manifold nut

Cable clamp

Manifold

L-bracket

Cable

clamp nut

and bolt

Remove the lock nut from the control cable

and thread the cable through the dash bracket.

Replace the nut over the control cable and fasten

the control cable securely to the bracket. Thread

control cable through the rewall. For best results,

use a wire hole near the top and center

of the rewall. You may have to drill a hole

on some models.

STEP 8:

Mount the manifold L-bracket to the manifold

in line with the swivel assembly. Use a manifold

bolt that is within 6 inches from the carburetor.

The manifold L-bracket may then be bent, if

necessary, to create better alignment. On some

four and in-line six cylinder engines, the L-bracket

can be mounted on the rewall or other location.

STEP 9:

Place the choke cable clamp over the choke

cable. Using the remaining screw and nut,

assemble to the manifold L-bracket. Use the

bracket hole giving the best alignment with the

swivel assembly.

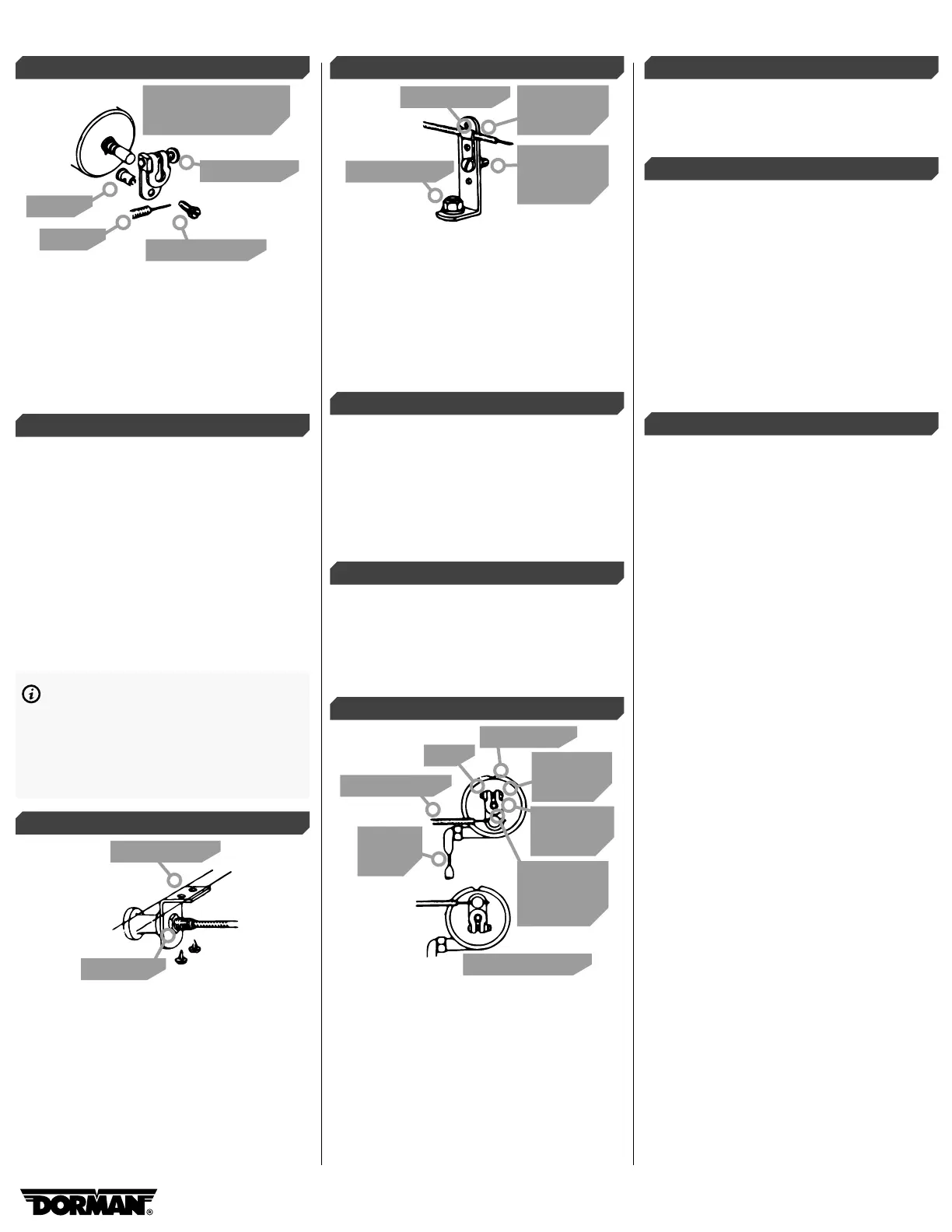

STEP 10:

Control cable

Nut

Machine

screw

Swivel

assembly

Plastic cap

Shaft

and lever

assembly

Alternate set-up

Crimp

tight

Determine the direction in which your choke

buttery operates, so that when installation is

completed, the choke buttery will close when

you pull out the control on the instrument

panel and open when you push it in. This is

done by having the swivel assembly point down

to the manifold or straight up. Once you have

determined the correct position, tighten the

screw nut assembly on the shaft.

STEP 11:

Insert the choke cable wire inside the cable and

through the hole in the collar tting referred to in

Step 4.

STEP 12:

To adjust the manual choke, have an assistant

sit in the automobile to depress and hold the

accelerator all the way down and operate the

choke by pulling it in and out. When the knob is

pulled all the way in against the dash bracket,

the choke buttery should be completely open.

If adjustment is needed, loosen the screw on the

choke wire, open the choke buttery to its upright

position and then retighten. Adjustments may

also be made by loosening and re-adjusting the

swivel assembly on the shaft. Tighten all ttings

and reinstall air lter.

STEP 13:

In the event the air lter housing interferes with

the swivel assembly, be sure the assembly is all

the way on the shaft, against the cap. If the swivel

assembly is in the up position and responsible

for the interference, disconnect the control cable

from the swivel assembly and the large L-bracket.

Re-route the cable around the carburetor. Re-

locate the large L-bracket on the opposite side of

the engine and mount it in a convenient location.

Loosen the swivel assembly and set it down as

shown in the top part of Step 10. Reconnect the

control cable to the bracket and swivel assembly

as fed from the other side of the carburetor.

This will allow the choke buttery to operate

normally with the swivel downward and should

solve clearance problems. The activator shaft

which extends beyond the swivel assembly may

also interfere with the air lter housing. This

extra length of shaft may be cut with a hacksaw.

Now you have a new, properly working manual

choke. If you have a heat tube connected to the

carburetor body, crimp tight with a pair of pliers,

as shown in Step 3.

Loading...

Loading...