©

DOSATRON INTERNATIONAL / 62

EN

© DOSATRON INTERNATIONAL / 61

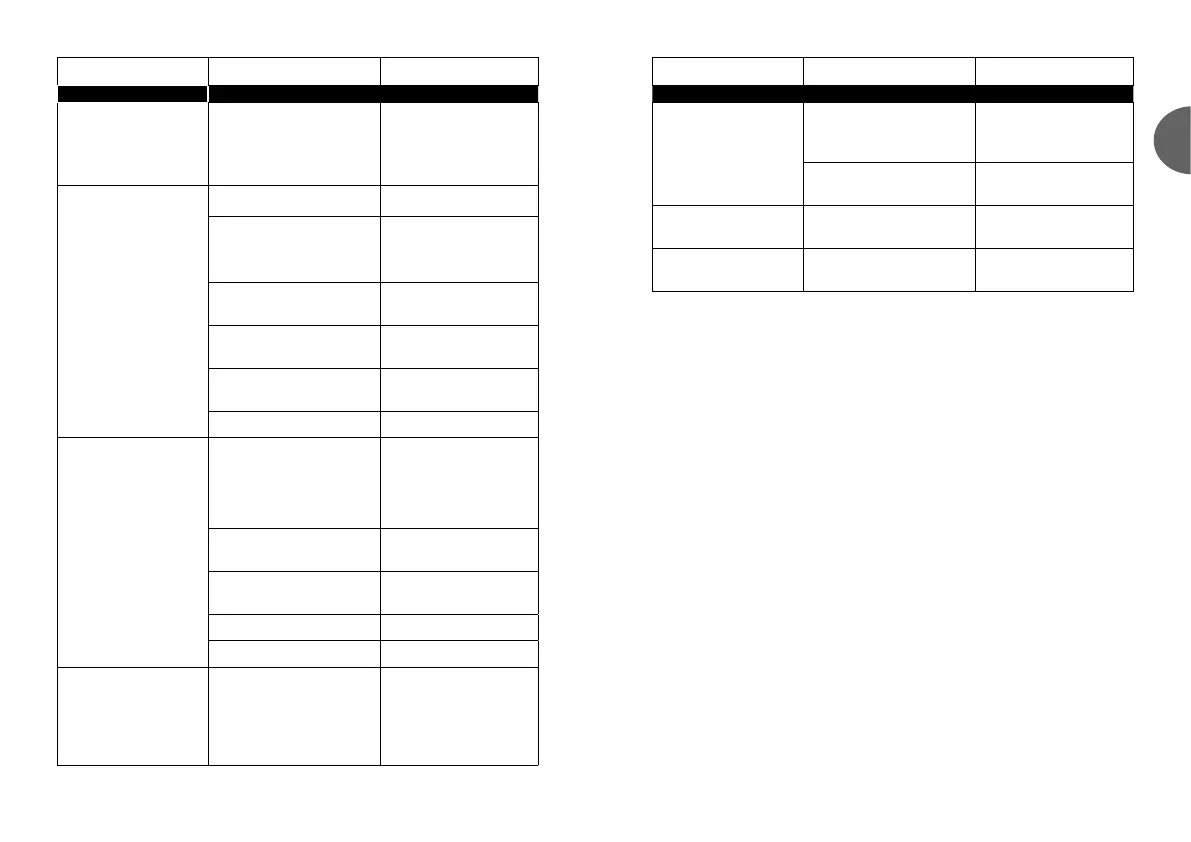

SYMPTOM CAUSE SOLUTION

Injection

Water flowing back

into concentrate

container.

Contamined, worn, or

missing check valve

parts.

Clean or replace it.

Check it has been

properly reassembled.

No suction of

concentrate.

The motor has stopped. See motor section.

Air leak (inlet) in the

suction tube.

Check the tightness

between nut and

suction hose.

Blocked suction tube or

clogged strainer.

Clean or replace

them.

Missing or worn suction

check valve o-ring.

Clean or replace it.

Missing or worn plunger

seal.

Clean or replace it.

Worn injection stem. Replace it.

Under dosing. Suction of air. 1. Check the tightness

of the nuts in the

injection area.

2. Check suction tube.

Dirty or worn check

valve seal.

Clean or replace it.

Maximum flow exceeded

(cavitation).

Reduce flow.

Worn plunger seal. Replace it.

Worn injection stem. Replace it.

Overdosing. Siphoning. Check your

installation.

Amend it and install

the necessary anti-

siphoning devices.

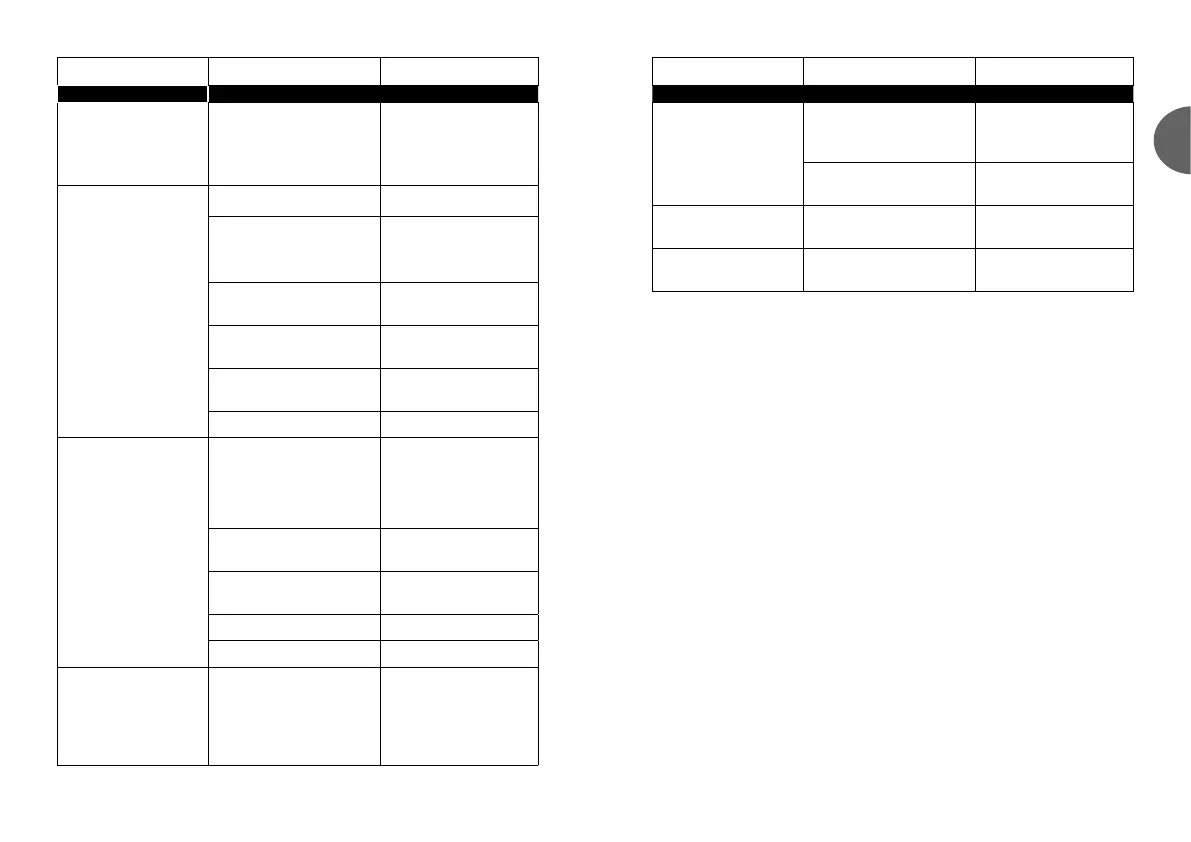

SYMPTOM CAUSE SOLUTION

Leaks

From the top cap,

actuator assembly or

transfer parts.

Screws untightened. Rescrew the screws.

It is not recommended

to open the top cap.

Dirty, not fitting or

missing seals.

Clean or replace the

seals.

From the by-pass. Dirty, worn or missing

seals.

Clean or replace the

seals.

From the injection

part.

Dirty, worn or missing

seals.

Clean or replace the

seals.

THE MANUFACTURER DECLINES ALL RESPONSIBILITY IF THE DOSATRON

IS USED IN CONDITIONS THAT DO NOT CORRESPOND TO THE OPERATING

INSTRUCTIONS.

Loading...

Loading...