73

Утилизация

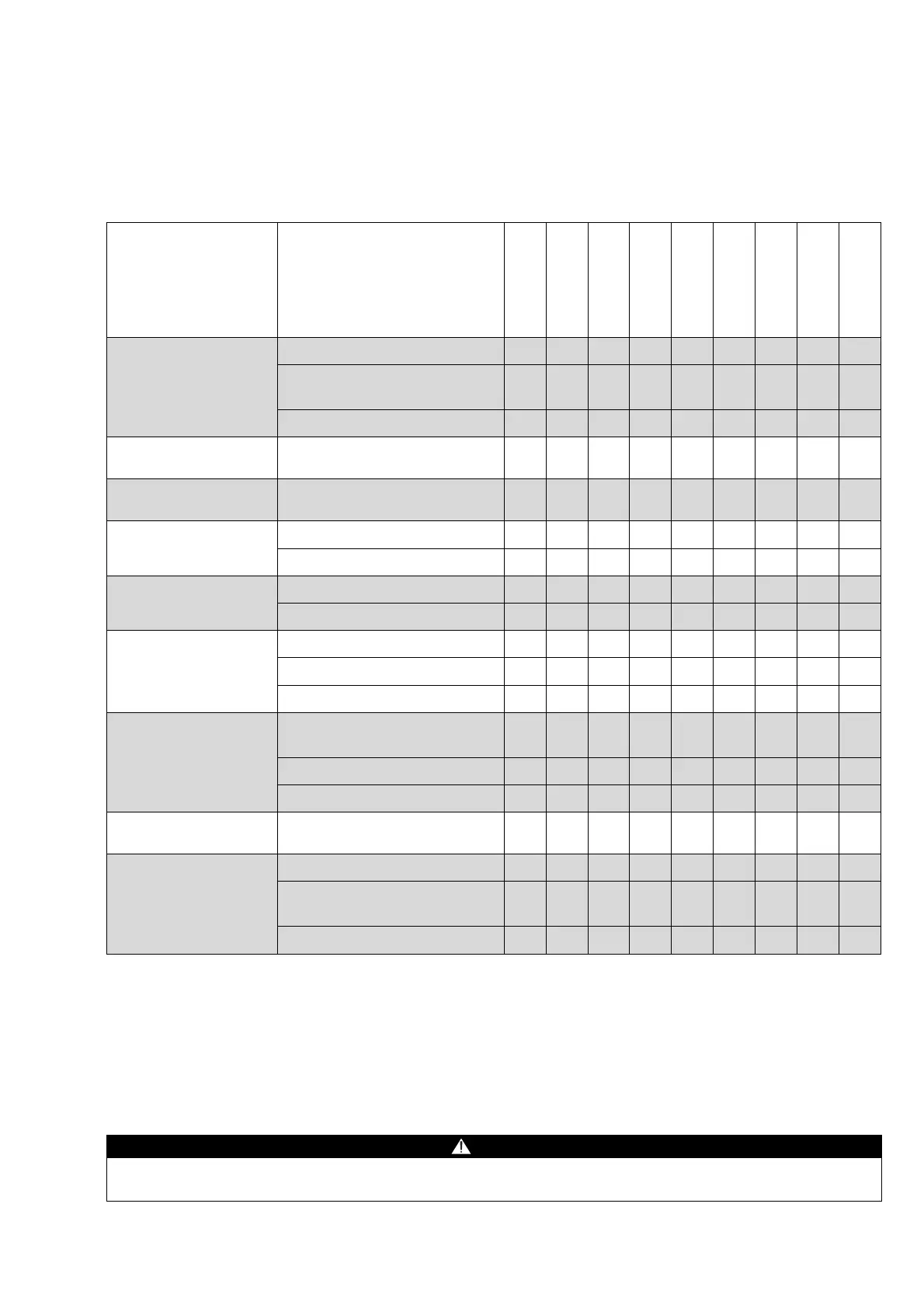

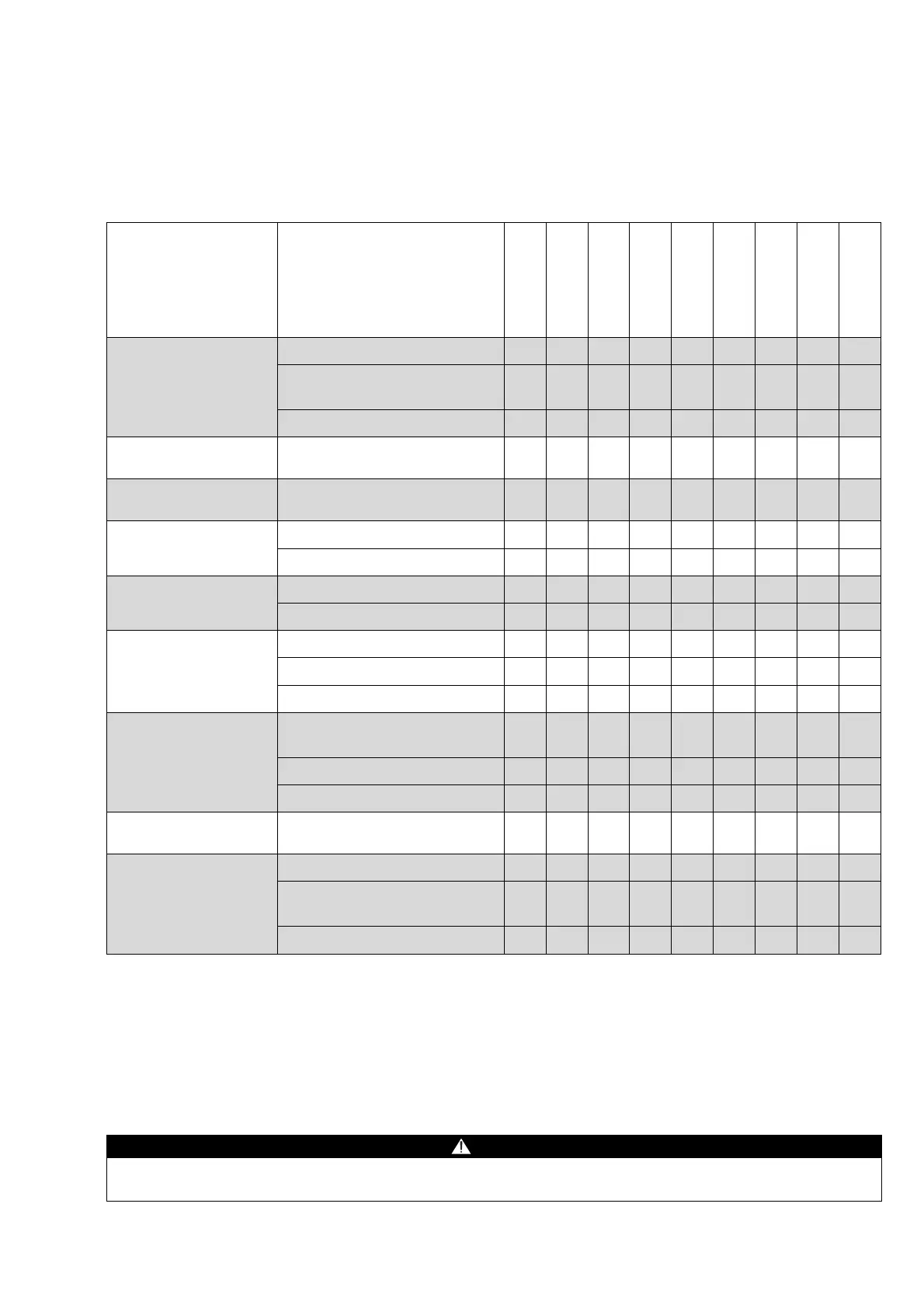

Maintenance Intervals

Part of the apparatus Work required

before approval

for use

1)

1) According to BGR 190 (valid for Germany).

before use

after use

half-yearly

annually

every 3 years

every 4 years

every 5 years

every 6 years

PSS BG 4 (complete)

Check readiness for operation X

Check correct functioning and

absence of leaks

X X X

2)

2) For apparatus in constant use.

X

3)

3) For reserve stocks (heed CO

2

absorber maintenance intervals, however).

Clean and disinfect X X

CO

2

absorber

(single-use cartridge)

Replace X X

4) 5)

4) Applies to apparatus stored in vehicles, tested as described on page 59 onwards and having a sealing cap R 33 588 fitted to the

plug-in connector.

5) Applies to apparatus stored stationary at a depot, tested as described on page 59 onwards and having a sealing cap R 33 588 fitted

to the plug-in connector.

X

6)

6) Stored stationary at a depot in the original packaging. Note "use by" date.

CO

2

absorber

(refill cartridge)

Fill according to filling instructions X X

5)

7)

7) Stored stationary at a depot when the CO

2

absorber was filled according to filling instructions, sealed with a plug and wrapped in a

polyethylene bag.

Inhalation and

exhalation valve

Test X

Replace X

2)

X

3)

O-ring on the

plug-in coupling

Examine X

Replace X

2)

X

3)

Pressure reducer

Thorough overhaul by experts X

Check high-pressure gasket X

Replace high-pressure gasket X

2)

X

3)

Oxygen cylinder

Official inspection by the Technical

Control Board (e.g. TÜV)

X

8)

8) Or testing according to the local requirements, which might show different figures.

Recharge X

Check charging pressure X

Control line and

medium-pressure hoses

Check X

Bodyguard

Check X

Comparative Bodyguard

measurement

X

9)

9) Test by trained personnel.

Replace battery X

DANGER

The maintenance intervals mentioned above must be strictly followed.

Failure to follow this warning could lead to death or serious injury.

Loading...

Loading...