3. Refuelling

WARNING!Beforellingtheproduct,ALWAYS

ensurethatthecontrolleverisinitslowest

position.ONLYusebutanegastofueltheproduct.

Important: This product is not shipped with butane gas

and MUST be fuelled before use.

1 Fig.

(A)

1. Turn the soldering iron upside-down and push the

butane can nozzle rmly into the lling valve (A).

2. Filling begins automatically and takes only a few

seconds.

The fuel level can be viewed through the window (B)

beneath the control lever (C).

3. Allow a few minutes after lling for the gas in the

product to stabilise.

WARNING!Allowescapedgastodispersebefore

lighting the soldering iron. NEVER light the

product while a gas canister is inserted into the

llingvalve.

4. IgnitionandUse

WARNING! Keep your hands and face away from

thebarrelwhenignitingandoperatingthe

product.Gripthesolderingironbythehandleonly.

1. Fuel the product and allow the gas to settle.

2. Move the control lever (C) to the ON position to start

the fuel supply.

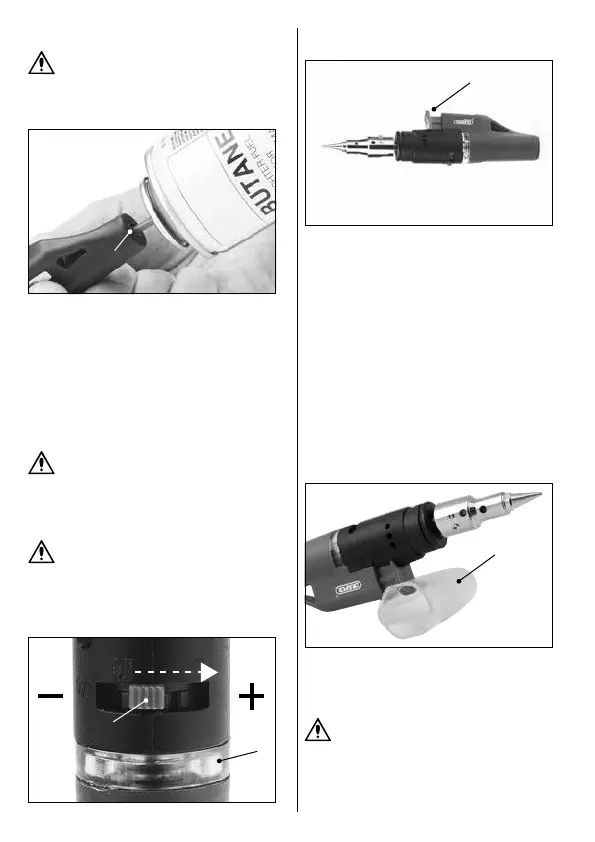

2 Fig.

(C)

(B)

3. Depress the ignition button (D) repeatedly until the

ame is lit.

3 Fig.

(D)

4. Adjust the size and temperature of the ame using

the control lever.

5. Allow approximately 30 seconds for the ame to

reach temperature, then direct the soldering tip

safely towards the workpiece.

6. Place the soldering tip against the appropriate area

of the workpiece and apply solder to the point of

contact as required.

Important: DO NOT apply excessive solder; use only

as much as is required for the connection.

7. To switch o the product, move the control lever

fully to the OFF position. Allow the soldering iron to

cool thoroughly.

– The clear lid (E) can be used as a stand while

cooling.

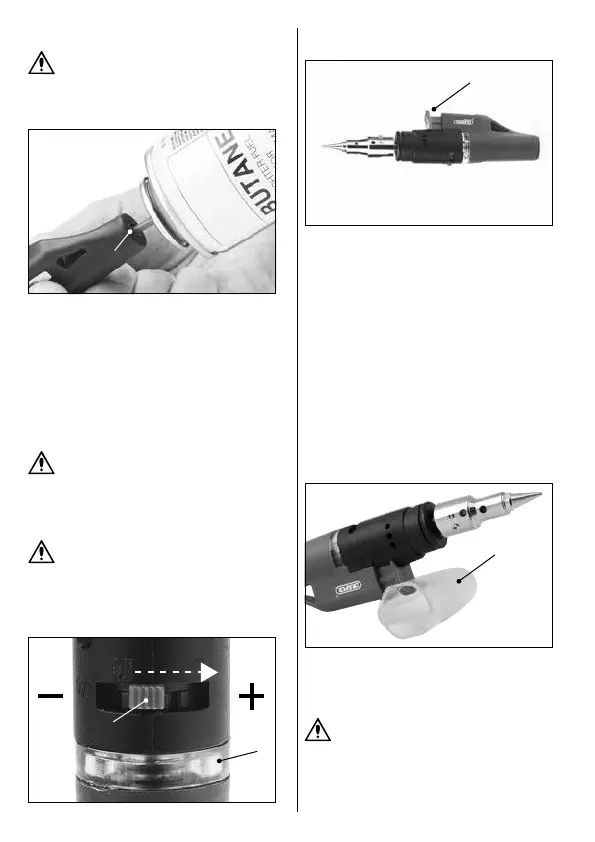

4 Fig.

(E)

Important: Avoid using the product in sideways or inverted

orientations as this may interrupt the ow of fuel to the

ame.

WARNING!ALWAYSensurethatthecontrollever

remainsintheopositionafteruse.Ifthefuel

supplyisre-engaged,residualheatcancause

reignitionwithoutoperatingtheignitionbutton.

Oncethetoolhascooled,followthenormal

ignition procedure to reignite.

Loading...

Loading...